Preparation method of biplanar super-resolution imaging lens

A super-resolution imaging, biplane technology, applied in the direction of lens, optics, instrument, etc., can solve the problem that it is difficult for the adjacent silver film and dielectric layer to meet the matching conditions, and achieve the effect of efficient processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, making a super-resolution imaging lens with double-plane zooming magnification, its specific manufacturing process is as follows:

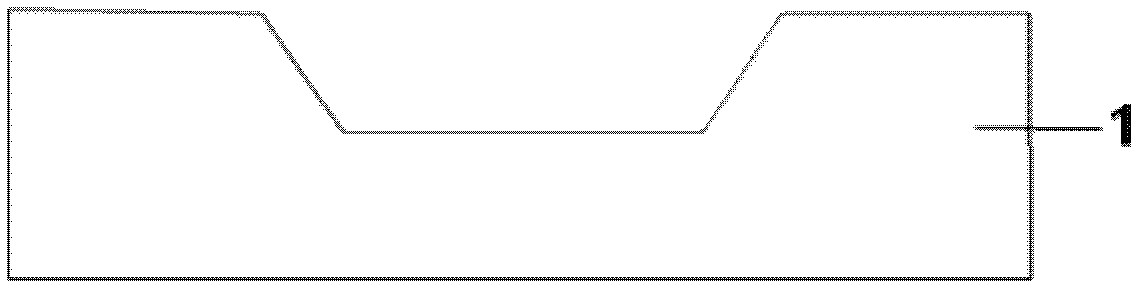

[0027] (1) in such as figure 1 Prepare a circular groove on the flat and clean quartz substrate as shown: figure 2 As shown, the bottom surface of the circular groove is parallel to the substrate surface, the diameter of the upper bottom of the circular groove is 800nm, the diameter of the lower bottom is 600nm, and the depth is 200nm.

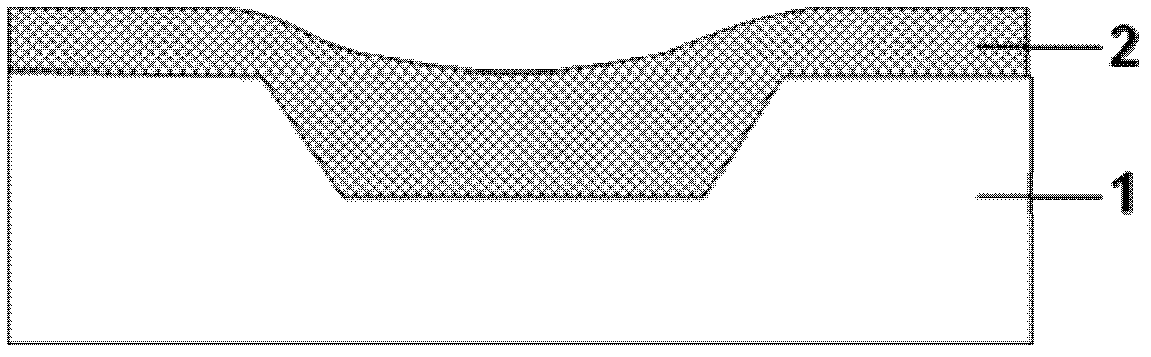

[0028] (2) if image 3 As shown, a layer of ethanol dispersion of silver nanoparticles with a silver concentration of 0.3g / ml is spin-coated on the substrate, and after drying at 160°C to remove the ethanol, the silver nanoparticles combine to form a silver film layer, in which the silver nanoparticles in the circular groove The thickness of the inner silver film layer is 15-30 nm. The thickness distribution law of the first silver film layer in the groove is: the central area of the gr...

Embodiment 2

[0031] Embodiment 2, making a super-resolution imaging lens with biplane zooming magnification, its specific manufacturing process is as follows:

[0032] (1) in such as figure 1 Prepare a square groove on the flat and clean quartz substrate as shown, the bottom surface of the groove is parallel to the substrate surface, the side length of the upper bottom of the groove is 1500nm, the diameter of the lower bottom is 1000nm, and the depth is 400nm.

[0033] (2) Spin-coat a layer of AgNO with a concentration of 2g / ml on the substrate 3 aqueous solution, and then post-bake at 80°C to evaporate the AgNO 3 Moisture in the aqueous solution, the substrate is subjected to ultraviolet light to make AgNO 3 Decompose into silver film layer, wherein the thickness of the silver film layer in the square groove is 10-20 nanometer. The thickness distribution law of the first silver film layer in the groove is: the central area of the groove is thin, and the edge area of the groove is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com