Preparation method of vanadate photocatalytic material

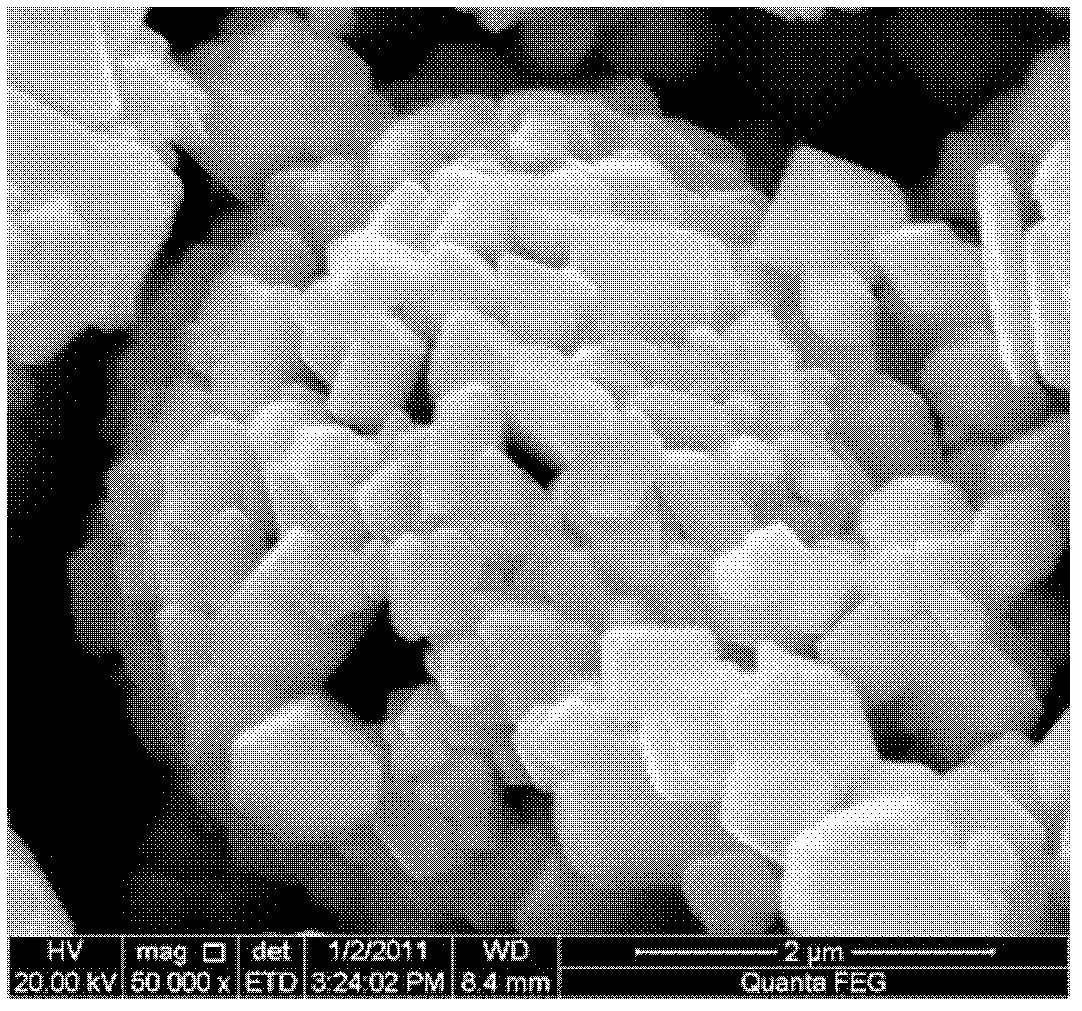

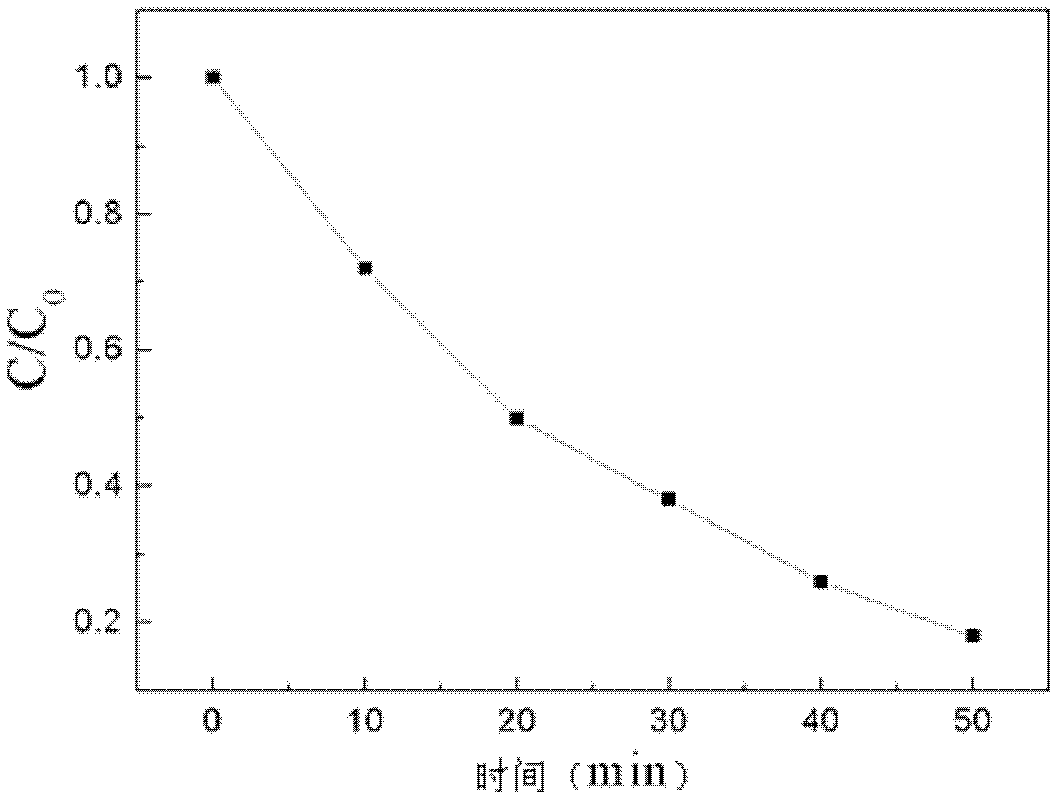

A technology of photocatalytic materials and vanadate, which is applied in the field of preparation of vanadate photocatalytic materials, can solve the problems of poor purity, high price, and difficult removal of BiVO4, and achieve the effect of uniform particles, high purity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

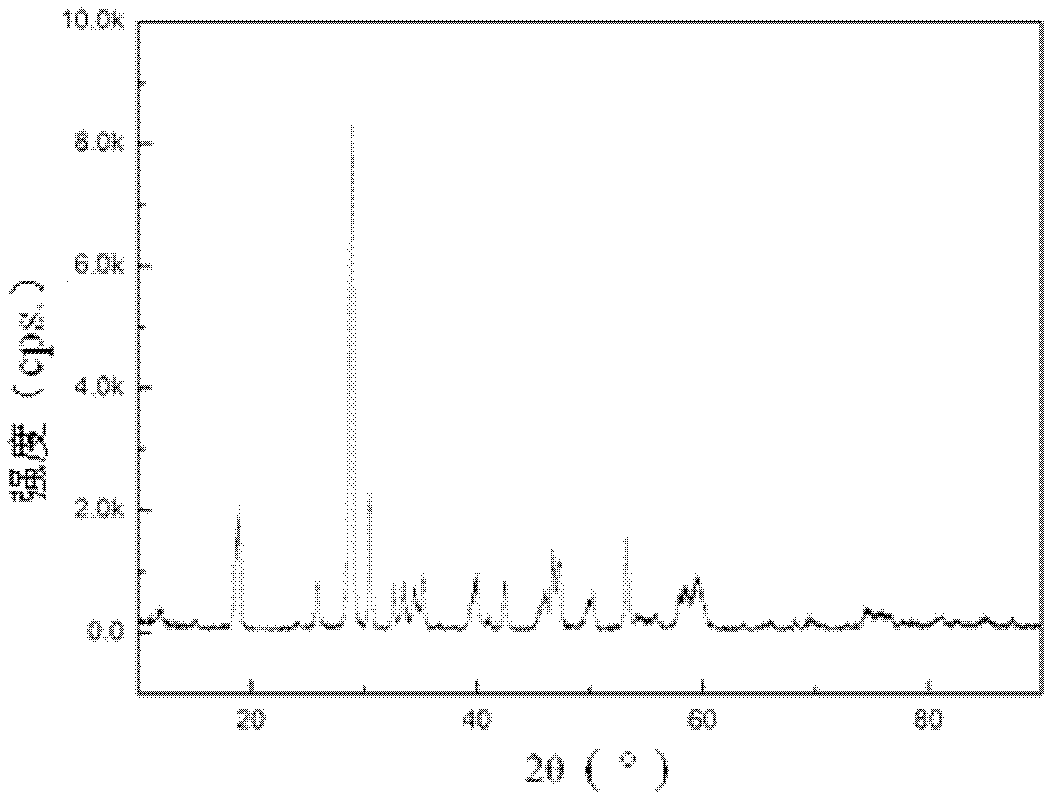

[0012] Specific embodiment one: the preparation method of a kind of vanadate photocatalytic material of the present embodiment is carried out according to the following steps:

[0013] 1. According to bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) and ammonium metavanadate (NH 4 VO 3 ) in a molar ratio of 1:1, weighed bismuth nitrate and ammonium metavanadate and added to nitric acid (HNO 3 ), under magnetic stirring, heated to 60-80°C to completely dissolve bismuth nitrate and ammonium metavanadate, and then adjust the pH value to 1-6.5 with ammonia water to obtain a mixed solution; wherein the mass percentage content of bismuth nitrate in the mixed solution 0.5% to 2%;

[0014] 2. Transfer the mixed solution obtained in step 1 to a polytetrafluoroethylene reactor, seal it and place it in an oven at 120-180°C for heat treatment for 6-12 hours;

[0015] 3. After the reaction kettle is lowered to room temperature, the obtained product is washed with ionized water, and then dried i...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, heat to a temperature of 65-75°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 1, heat to a temperature of 70°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com