Process for recycling aluminum hydroxide from acid wastewater containing aluminum ions

A technology of acidic wastewater and aluminum hydroxide, applied in aluminate/alumina/aluminum hydroxide purification, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of aluminum hydroxide having no recycling value, solubility Problems such as many impurities and wide particle size distribution have achieved significant social and economic benefits, scientific process routes, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

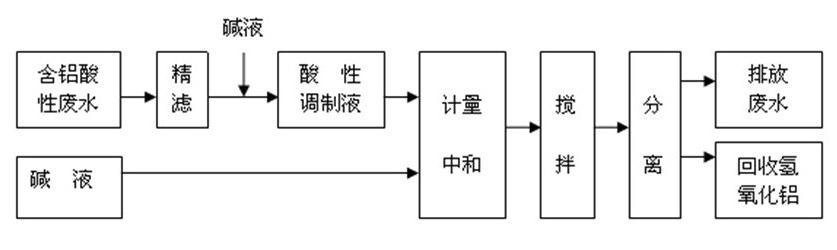

[0016] The present invention reclaims the technique of aluminum hydroxide from the acidic wastewater containing aluminum ions, see figure 1 , take the following process steps: first fine filter the aluminum-containing acidic wastewater, then add lye to prepare a pH 3.0 preparation solution, use a metering pump to absorb the preparation solution and lye respectively for instantaneous neutralization, and the suspension after neutralization The liquid enters the stirring tank and stirs, so that the small particles of aluminum hydroxide gradually disappear, and the large particles of aluminum hydroxide gradually grow up; separation; waste water is discharged up to the standard; aluminum hydroxide sludge is recycled.

[0017] In the above steps, the aluminum-containing acidic wastewater is subjected to fine filtration to remove the suspended solids; soluble alkali is added to the fine filtrate to adjust the pH to 3.0 to make a preparation solution; Neutralization; stirring the neut...

Embodiment 2

[0020] The technology of the present invention reclaims aluminum hydroxide from aluminum-containing ion acidic waste water, see figure 1 , the technology includes the following steps: (1) pretreatment of acidic wastewater containing aluminum ions, (2) neutralization to completely convert aluminum ions into insoluble aluminum hydroxide, and then after slow stirring at neutralization temperature, Solid-liquid separation, discharge of waste water up to standard, recycling of insoluble aluminum hydroxide sludge.

[0021] The pretreatment of the acidic wastewater containing aluminum ions described in step (1) refers to the fine filtration of the acidic wastewater containing aluminum to remove the suspended matter in it to obtain clear and transparent acidic wastewater containing aluminum; and then the finely filtered acidic wastewater containing The aluminum acid wastewater is prepared by adding a neutralizing agent, the neutralizing agent is a soluble alkali, and the pH value is c...

Embodiment 3

[0026] The process for recovering aluminum hydroxide from acid wastewater containing aluminum ions of the present invention comprises the following steps: (1) pretreating the acid wastewater containing aluminum ions first, (2) neutralizing to completely convert aluminum ions into Insoluble aluminum hydroxide, after slow stirring at neutralization temperature, solid-liquid separation, discharge of waste water up to standard, recycling of insoluble aluminum hydroxide sludge.

[0027] The pretreatment of the acidic wastewater containing aluminum ions described in step (1) refers to the fine filtration of the acidic wastewater containing aluminum to remove the suspended matter in it to obtain clear and transparent acidic wastewater containing aluminum; and then the finely filtered acidic wastewater containing The aluminum acid wastewater is prepared by adding a neutralizing agent, the neutralizing agent is a soluble alkali, and the pH value is controlled to be 4 during preparation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com