Automatic slag adding machine and slag adding method

A technology of automatic slag adding machine and mold slag, which is applied in the field of automatic slag adding machine and slag adding, which can solve the problems that the shape of the crystallizer cannot be matched, the mold slag is not heated, and the nozzle cannot be covered, so as to reduce the oxide impurities of molten steel and reduce the The labor intensity of workers and the effect of reducing operational accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

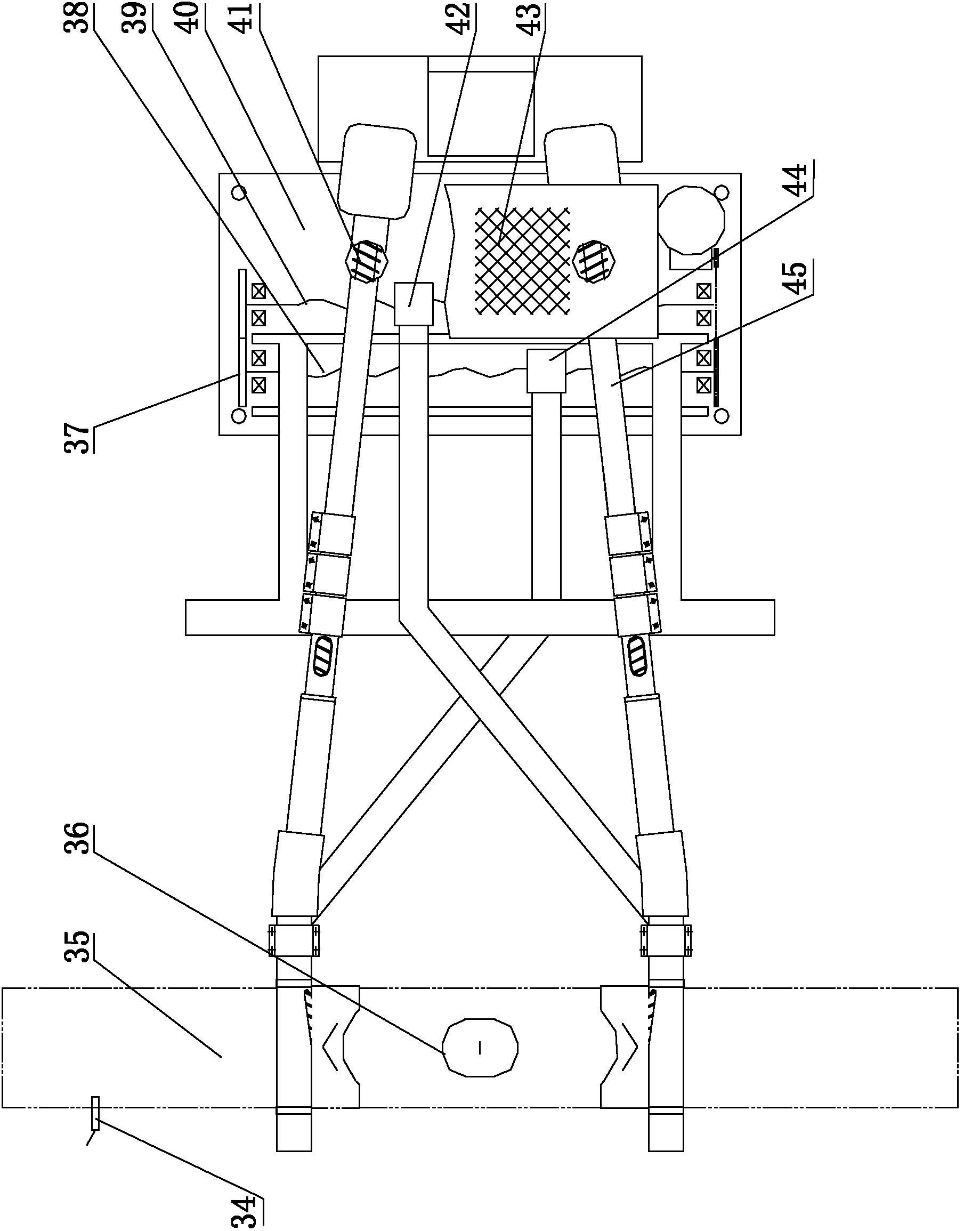

[0030] The present invention can select 1 set of conveying systems, also can select 2 sets of conveying systems, also can select a larger number of conveying systems. This embodiment only describes the embodiment in which 2 sets of conveying systems are selected.

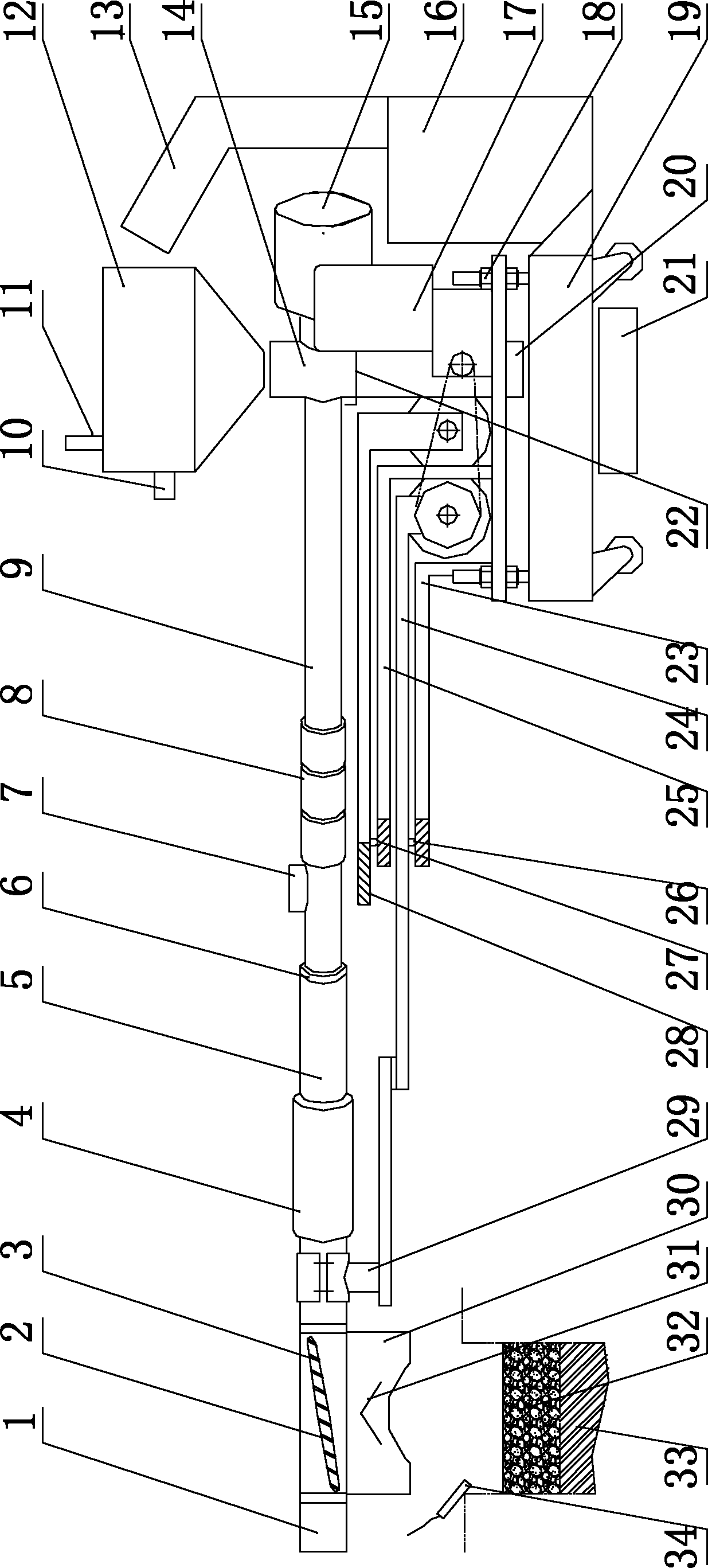

[0031] see Figure 1 to Figure 2 , an automatic slag adding machine, including a trolley mechanism 19, two sets of conveying systems are installed on the trolley mechanism in a horizontally swingable manner—the left conveying system and the right conveying system, the conveying system is near the tail A material storage system is installed, and the head of the material conveying system is a blanking tube 1, which is connected with the swing arm system, and the blanking tube moves linearly along the crystallizer 35.

[0032] Each set of feeding system is composed of feeding motor 15, feeding pipe 9, axial sealing ring 6, telescopic pipe 5, elastic connecting pipe 4, and feeding pipe 1, which are connected in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com