Preparation method of silver tin oxide or silver tin oxide and indium oxide material

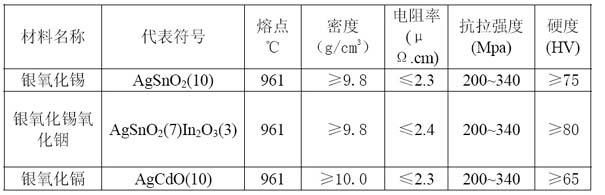

A technology of silver tin oxide and tin oxide, which is applied in the field of preparation of silver tin oxide or silver tin oxide indium oxide materials, can solve the problems of limited service life, toxicity, melting point of silver cadmium oxide, low hardness, etc., and achieve high thermal stability , The effect of reducing the size of the contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of silver tin oxide material:

[0058] 1) Preparation of complexes; take silver nitrate and dissolve it in water and pour it into a complexation tank, add high-purity ammonia water until the liquid surface is clarified, form a complex and then add water to dilute; the silver content in the complex after dilution is 0.2 Kg / L;

[0059] 2) Equipped with hydrazine hydrate solution; take the hydrazine hydrate compound and dilute it with water; the concentration is 10%;

[0060] 3) Reaction: Put tin oxide fine powder, hydrazine hydrate solution, and the complex into a container for reaction, wherein the ratio of substances is:

[0061] Tin oxide powder (Kg): hydrazine hydrate solution (L): complex (L) = 0.15: 1: 2;

[0062]4) Filtration; the reacted mixture is filtered using a cloth bag filter; solids are obtained;

[0063] 5) Cleaning; the solid matter is cleaned until the pH of the cleaning solution after cleaning is 7.4;

[0064] 6) Drying: dry th...

Embodiment 2

[0076] 1) Preparation of complexes; take silver nitrate and dissolve it in water and pour it into a complexation tank, add high-purity ammonia water until the liquid surface is clarified, form a complex and then add water to dilute; the silver content in the complex after dilution is 0.21Kg / L;

[0077] 2) Equipped with hydrazine hydrate solution; take the hydrazine hydrate compound and dilute it with water; the concentration is 12%;

[0078] 3) Reaction: Put tin oxide fine powder, hydrazine hydrate solution, and the complex into a container for reaction, wherein the ratio of substances is:

[0079] Tin oxide powder (Kg): hydrazine hydrate solution (L): complex (L) = 0.2:1:2;

[0080] 4) Filtration; the reacted mixture is filtered using a cloth bag filter; solids are obtained;

[0081] 5) Cleaning: Clean the solid matter until the pH of the cleaning solution is 7.3 after cleaning;

[0082] 6) Drying: dry the cleaned solids; dry at 100°C for 1.2 hours in a baking method;

...

Embodiment 3

[0094] 1) Preparation of complexes; dissolving silver nitrate in water and pouring it into a complexation tank, adding high-purity ammonia water until the liquid surface is clarified, forming complexes and then adding water to dilute; the silver content in the complexes after dilution is 0.23Kg / L;

[0095] 2) Equipped with hydrazine hydrate solution; take the hydrazine hydrate compound and dilute it with water; the concentration is 15%;

[0096] 3) Reaction: Put tin oxide fine powder, hydrazine hydrate solution, and the complex into a container for reaction, wherein the ratio of substances is:

[0097] Tin oxide powder (Kg): hydrazine hydrate solution (L): complex (L) = 0.4:1:2;

[0098] 4) Filtration; the reacted mixture is filtered using a cloth bag filter; solids are obtained;

[0099] 5) Cleaning; the solid matter is cleaned until the pH of the cleaning solution after cleaning is 7.2;

[0100] 6) Drying: dry the cleaned solids; dry at 150°C for 2 hours in a baking met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com