Petroleum coke powder full oxygen combustor

An all-oxygen combustion, petroleum coke powder technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of not energy saving and environmental protection, insufficient combustion of coke powder, low utilization rate of coke powder, etc. Reasonable structure, improved utilization, convenient and quick loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

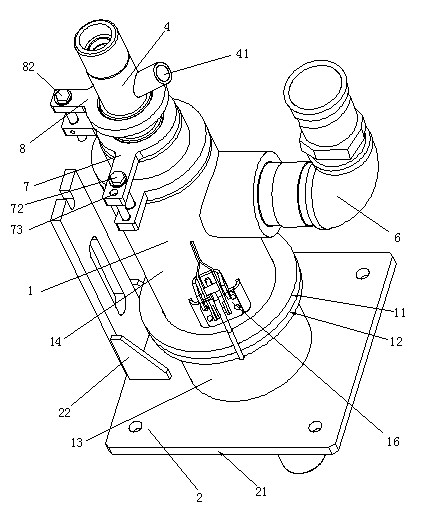

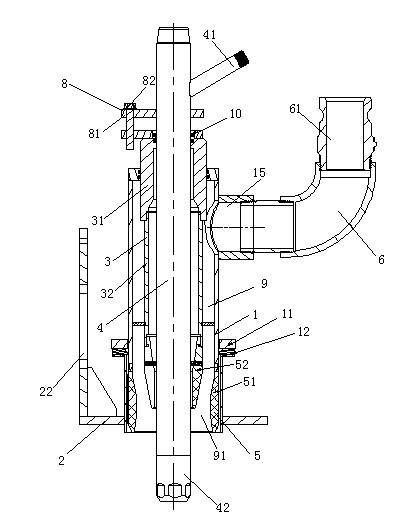

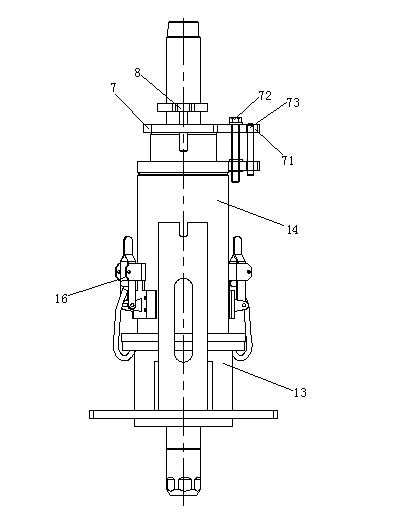

[0018] The present invention is a petroleum coke powder full-oxygen (pure oxygen) combustion-supporting burner. In this embodiment, as figure 1 , 2 As shown, it includes an outer pipe 1, a burner bracket 2 for fitting the outer pipe 1, an inner pipe 3 fitting in the outer pipe 1, a coke powder gun 4 fitting in the inner pipe 3 and extending into the combustion kiln , and the Venturi tube 5 installed on the head end of the inner tube 3 and the outer tube 1; Inner and outer tube 52; the outer wall of the outer tube 1 and the outer wall of the inner tube 3 surround an oxygen channel 9, and the tail end of the oxygen channel 9 is connected with the external oxygen supply equipment through the oxygen interface 15 arranged on the outer tube 1, and the oxygen channel 9 The head end forms an injection port 91 through the Venturi channel of the Venturi tube 5, and the tail end of the coke powder gun 4 is connected with an external coke powder supply device, and is provided with an ato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com