Magnetic-electric composite material and preparation method thereof

A magnetoelectric composite material and composite material technology, applied in the field of magnetoelectric composite materials and their preparation, can solve the problems of not being able to significantly improve the magnetoelectric conversion coefficient, weaken the stress transmission of the magnetostrictive layer to the piezoelectric layer, etc., and achieve increased force Transmission, the effect of the large magnetoelectric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

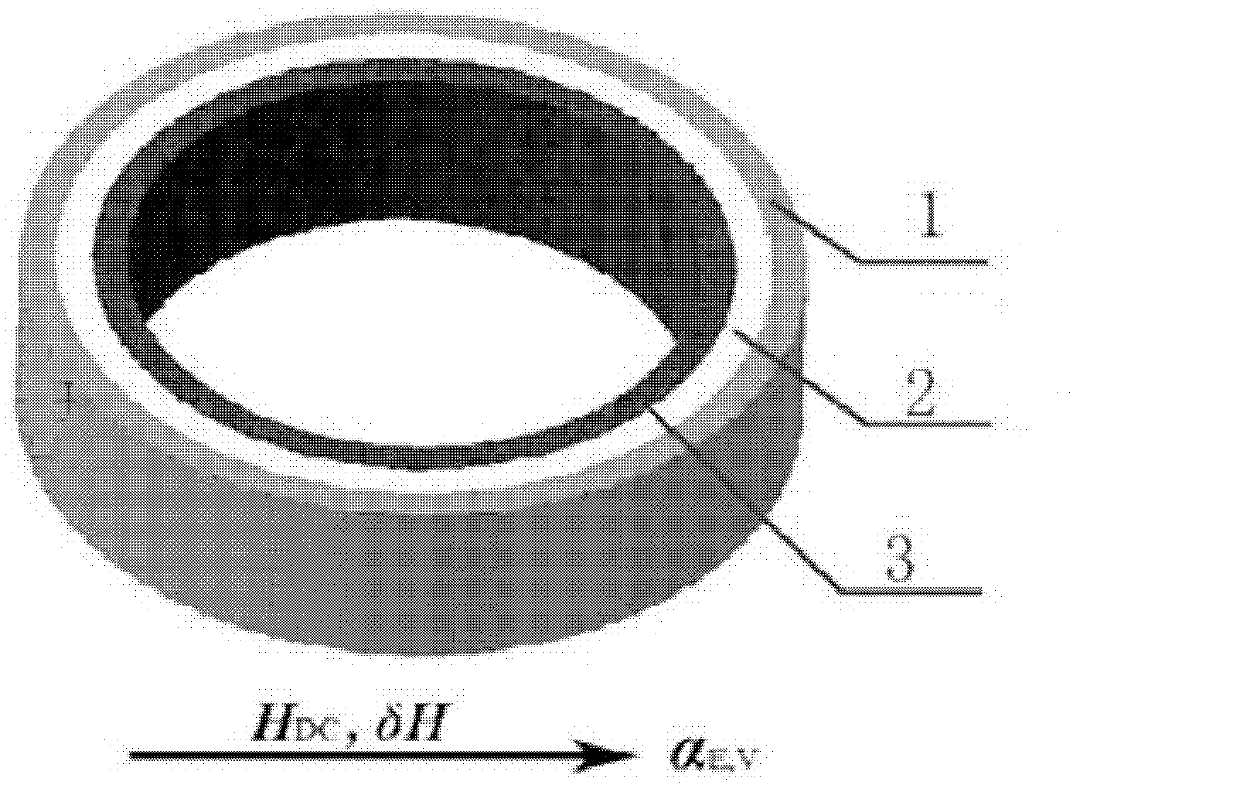

[0025] Cut the PZT into circular samples with the size of f25mm×f23mm×5mm, and perform metallization after ultrasonic cleaning in a mixed solution of alcohol and acetone for 10 minutes. First, put the sample in 0.08M stannous chloride solution, sensitize it at room temperature for 10 minutes, take it out and rinse it with distilled water; put the sample in 0.001M palladium chloride solution, activate it at room temperature for 10 minutes, take it out Rinse with distilled water; finally place the sample in 0.2M sodium hypophosphite solution for 30-60 seconds, and complete the PZT metallization treatment after rinsing with distilled water.

[0026] PZT is put into the prepared electroless plating solution to perform electroless plating of positive magnetostrictive material FeCo. First, weigh the medicines required for the chemical plating FeCo plating solution formula, dissolve them separately and mix them, adjust the pH value to 9 with NaOH solution, and then dilute to the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com