Metal powder-cored flux-cored wire for welding chrome-molybdenum steel and its preparation and application

A technology of flux-cored welding wire and metal powder core, applied in welding equipment, metal processing equipment, welding media, etc., can solve the problems of poor impact toughness and crack resistance, achieve good cold crack resistance, improve room temperature impact toughness, and weld Good sewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

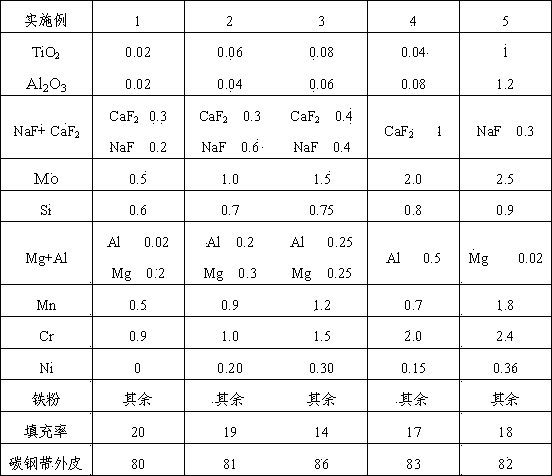

[0030] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

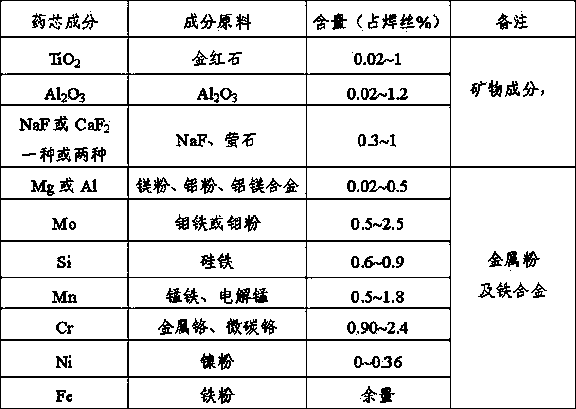

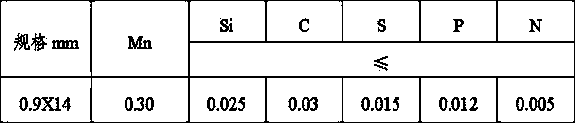

[0031] The metal powder-cored flux-cored welding wire for welding chromium-molybdenum steel of the present invention includes a carbon steel sheath and powder filled in the carbon steel sheath, wherein the medicine powder contains the following components and their percentages of the total weight of the welding wire (medicine powder + carbon steel sheath) The percentages are as follows: TiO 2 0.02~1%;Al 2 o 3 0.02~1.2%; Si 0.6~0.9%; Mn 0.5~1.8%; Cr 0.90~2.4%; NaF or CaF 2 One or its arbitrary ratio mixture 0.3~1%; Mg or Al one or its arbitrary ratio mixture 0.02~0.5%; Mo 0.5~2.5%; Ni 0~0.36%.

[0032] The weight of the powder is 14-20% of the total weight of the welding wire, and the balance is Fe.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com