Production method of toothpaste-grade heavy calcium carbonate

A technology of heavy calcium carbonate and a production method, which is applied in the field of calcium carbonate, can solve the problems of difficult control of heavy metals and microbial indicators, and many harmful substances, and achieves the effects of low heavy metal and microbial indicators, high whiteness, and high output rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The production method of this toothpaste grade ground calcium carbonate, the method comprises steps as follows:

[0020] (1) For the initial beneficiation, after the ore arrives at the factory, the fixed-point sampling method is used to detect the whiteness, main content, iron content and other items of the ore. Generally, the whiteness is required to be 97%, and the main content is 99.5%-100.5%. Iron content ≤ 200ppm, select high-quality ore raw materials;

[0021] (2) One-time cleaning, the ore raw materials that pass the test enter the primary washing machine for cleaning, and initially wash off the impurities such as yellow mud and gravel adhering to it;

[0022] (3) Mineral beneficiation again, the ore after the first cleaning must be piled into the designated storage place, the place must be free from pollution and bacteria growth, keep clean and tidy, and then carry out manual beneficiation. At the same time, remove the yellow skin attached to the calcite, and p...

Embodiment 2

[0027] Embodiment 2: the difference from Example 1 is: in the grinding step, add 0.01% of the rare earth material of the ore raw material weight, the rare earth material is one or more of lanthanum, cerium, praseodymium, neodymium, add a trace amount of rare earth material, Make the product quality more stable, and can play a role in degrading toxic substances to a certain extent.

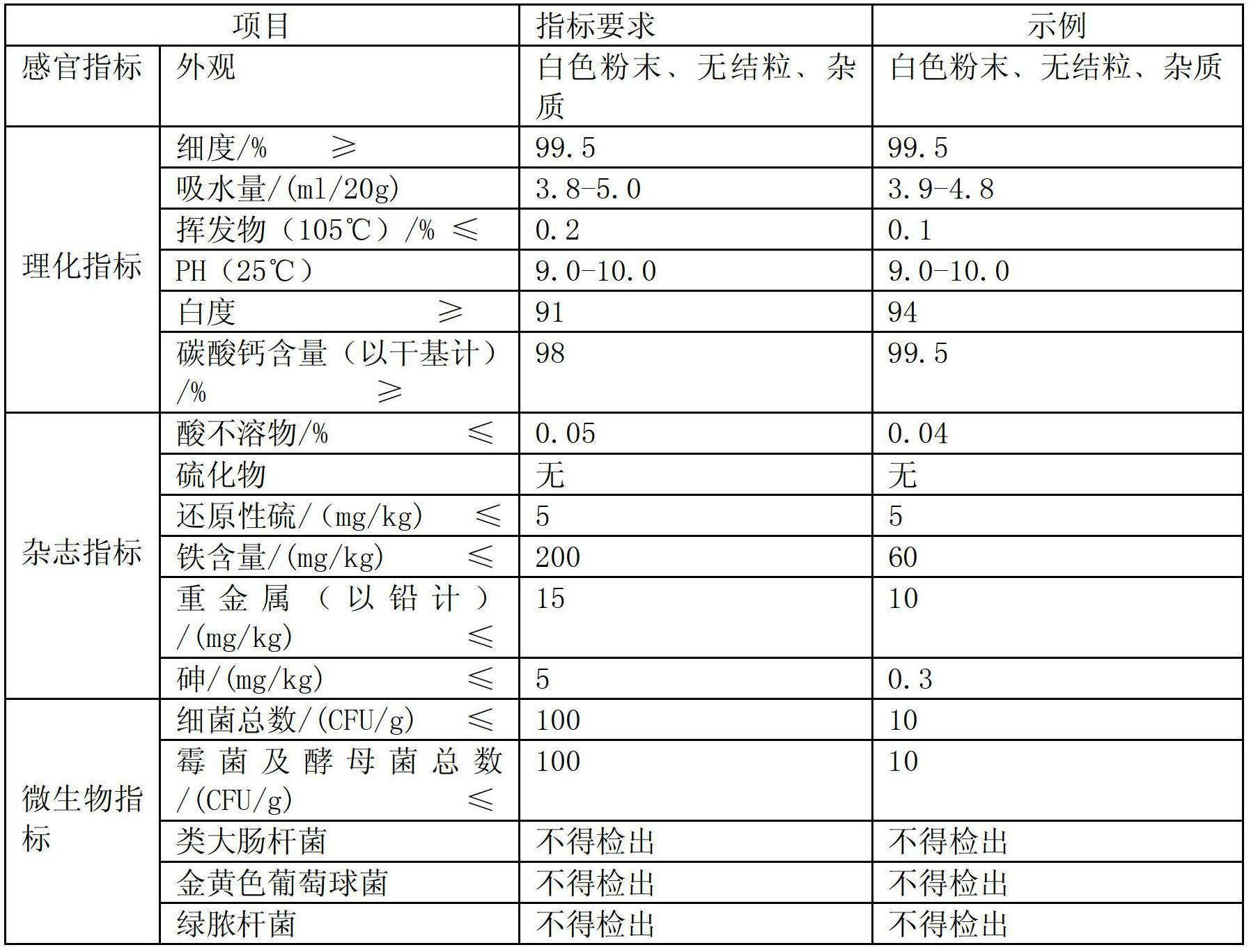

[0028] Table 1 Comparison of physical and chemical indicators of calcium carbonate

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com