Pre-treatment system for acid water of oil refinery

A sour water and oil refinery technology, which is applied in the field of sour water pretreatment system in oil refineries, can solve the problems of unsatisfactory vapor-liquid balance in the stripper, large environmental pollution, and poor quality of liquid ammonia, etc., and achieve stable desulfurization effect , avoid secondary pollution, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

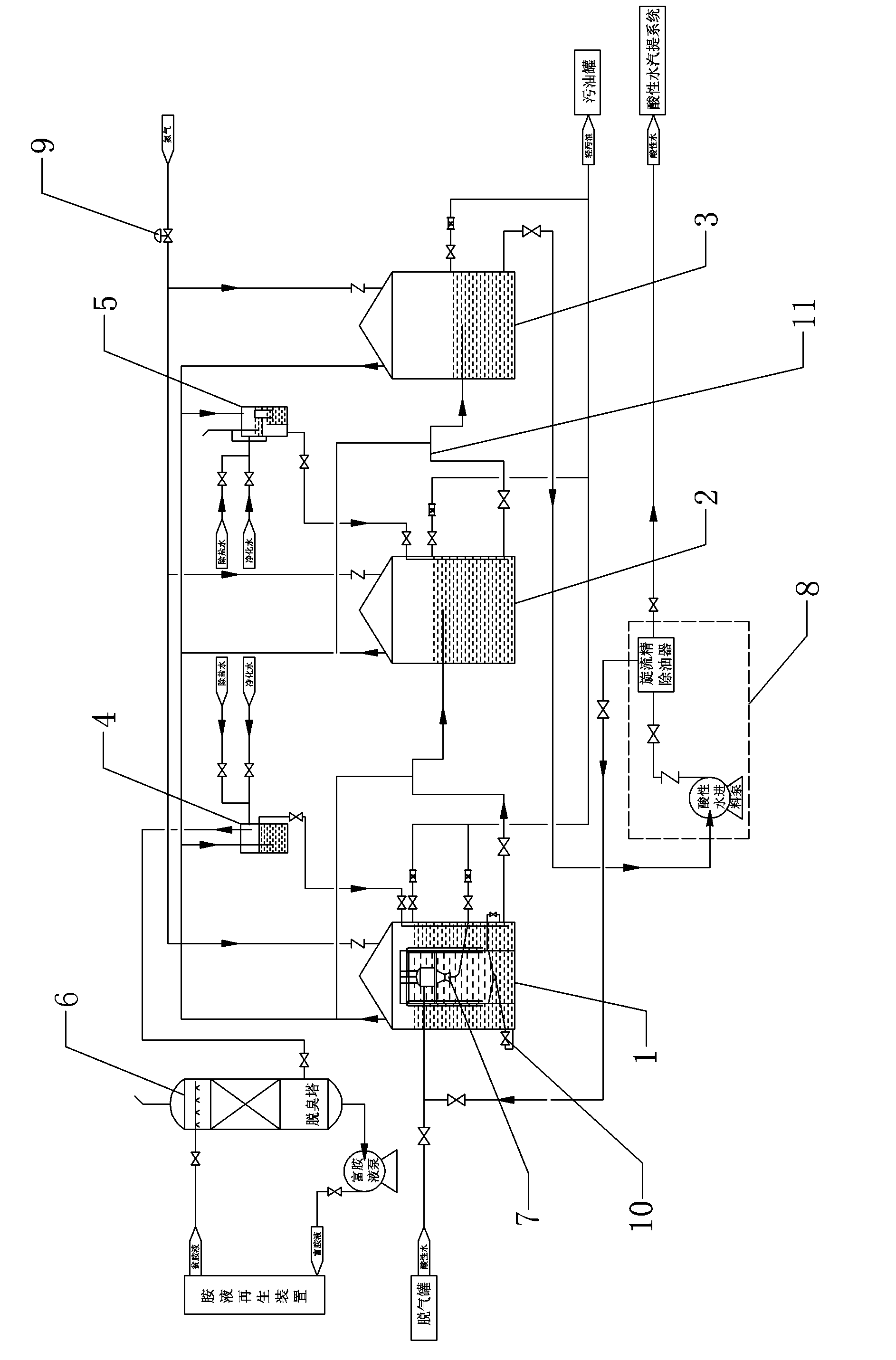

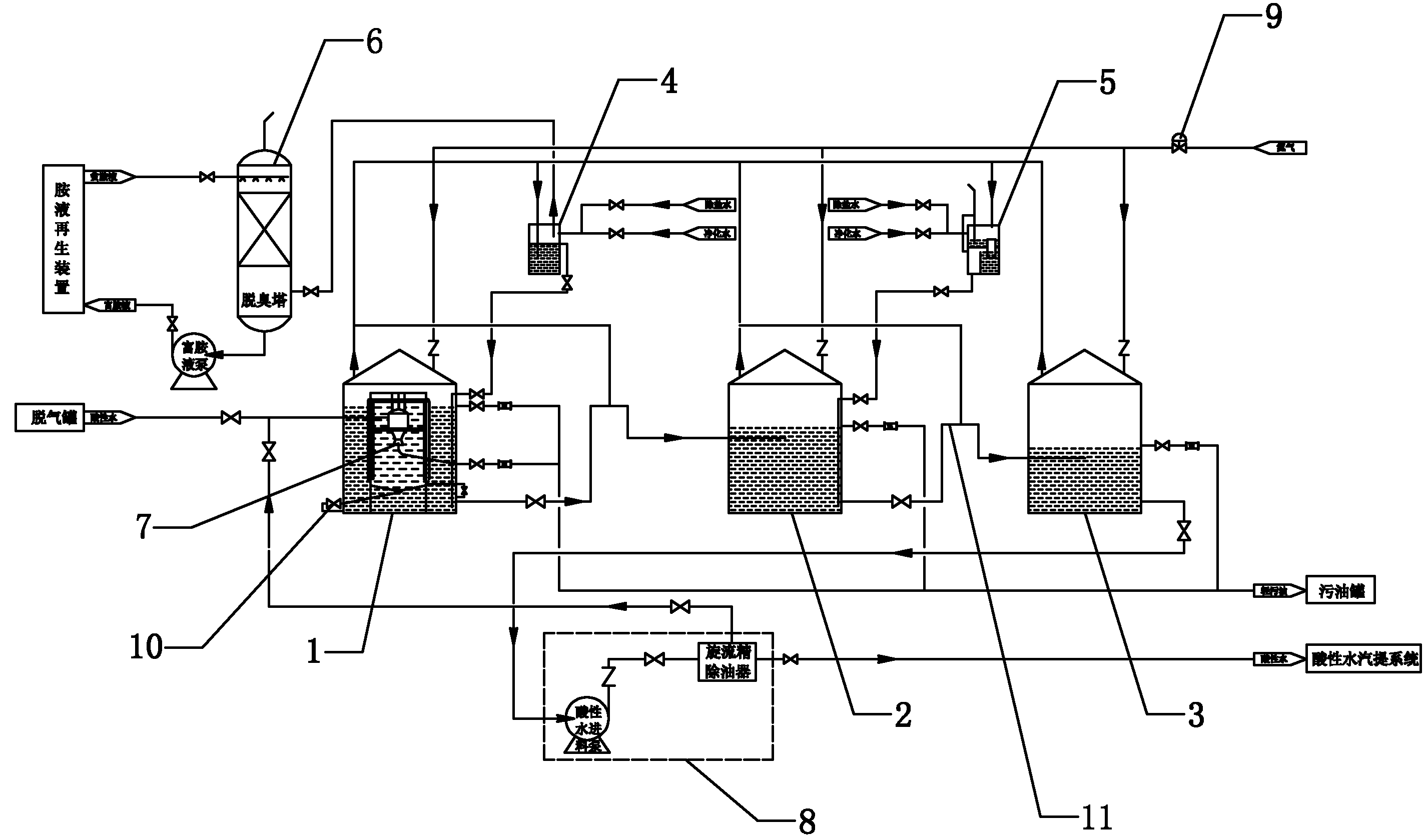

[0026] see figure 1 , an acidic water pretreatment system in an oil refinery is mainly composed of 3 acidic water storage tanks connected in sequence, 2 water-sealed tanks, 2 sets of impurity and oil removal equipment, and 1 set of acidic water top gas degassing and deodorizing equipment 6; The above three acidic water storage tanks include impurity and oil removal tank 1, stabilization tank 2 and stripper feed tank 3; two water seal tanks include positive pressure water seal tank 4 and safety water seal tank 5; two sets of impurity removal The oil removal equipment includes a tank-in-tank oil removal and impurity removal equipment 7 and a cyclone fine oil removal equipment 8 . The tank-in-tank degreasing and impurity removal is built in the impurity and oil removal tank 1, and the raw acidic water is connected to the inlet of the impurity and oil removal tank 1 through the degassing tank; Between, the outlet of stabilizing tank 2 and the inlet of stripper feed tank 3 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com