A kind of preparation method of sulfonated polyphenol film

A sulfonated polyphenol and thin film technology, applied in the field of electrochemical preparation, can solve problems such as polymer membrane materials that have not yet been seen, and achieve the effects of facilitating preparation routes, improving electrical conductivity, and improving rate self-limiting problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

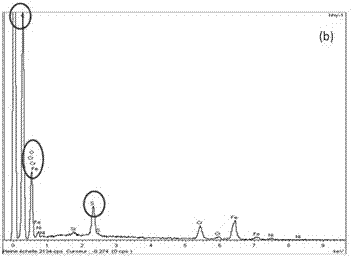

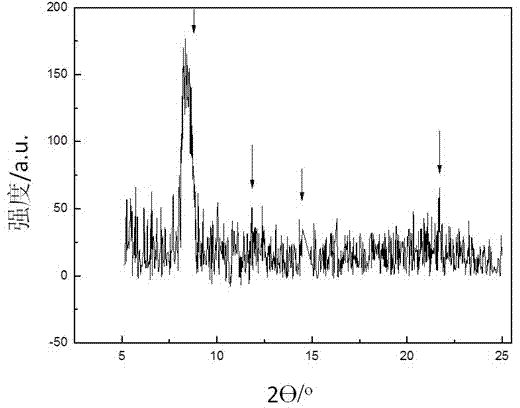

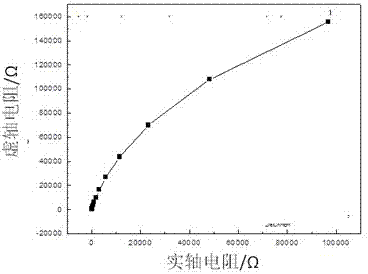

[0032] A sulfonated phenol aqueous solution with a concentration of 0.1 mol / L and pH=1 was used as the electrolyte solution, and three electrodes were used as electrodes. The three electrodes were working electrodes (disc stainless steel electrodes) and reference electrodes (saturated silver / silver chloride). Electrode) and counter electrode (platinum sheet electrode), and add supporting electrolyte sulfuric acid in the electrolyte solution to make the concentration of supporting electrolyte 0.05mol / L, and then perform cyclic voltammetry scan at room temperature in the voltage range of 0.6 to 1.6V ,Such as Figure 5 As shown, a yellow sulfonated polyphenol (polymer of sulfonated phenol) film is formed on the surface of the working electrode.

Embodiment 2

[0034] A sulfonated phenol aqueous solution with a concentration of 0.005 mol / L and pH=6.3 was used as the electrolyte solution, and three electrodes were used as electrodes. The three electrodes were working electrodes (sheet carbon electrodes) and reference electrodes (saturated silver / silver chloride electrodes). ) And the counter electrode (platinum wire electrode), carry out cyclic voltammetry scanning in the voltage range of 0.6~1.6V at 30℃, and carry out anodization reaction to realize the electrochemical polymerization of monomers, such as Image 6 As shown, a brown-yellow sulfonated polyphenol (polymer of sulfonated phenol) film is formed on the surface of the working electrode.

Embodiment 3

[0036] A sulfonated phenol aqueous solution with a concentration of 0.1 mol / L and pH=3 was used as the electrolyte solution, and three electrodes were used as electrodes. The three electrodes were the working electrode (nano-tube zirconia electrode) and the reference electrode (saturated silver / silver chloride). Electrode) and counter electrode (platinum mesh electrode), and add supporting electrolyte sulfuric acid to the electrolyte solution to make the concentration of supporting electrolyte 0.1mol / L, and then carry out cyclic voltammetry in the voltage range of 0.6~1.8V at 60℃ Scan, perform anodization reaction to realize the electrochemical polymerization of monomers, such as Figure 7 As shown, a yellow sulfonated polyphenol (polymer of sulfonated phenol) film is formed on the surface of the working electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com