Preparation method of industrial hemp full stalk pulp

A technology of industrial hemp and hemp stalks, which is applied in pulp beating/refining methods, pulping with inorganic alkali, non-woody plant/crop pulp, etc. It can solve problems such as complicated processes, waste of resources, and large differences in organizational structure , to achieve the effect of increasing pulp yield, reducing pulp dust, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

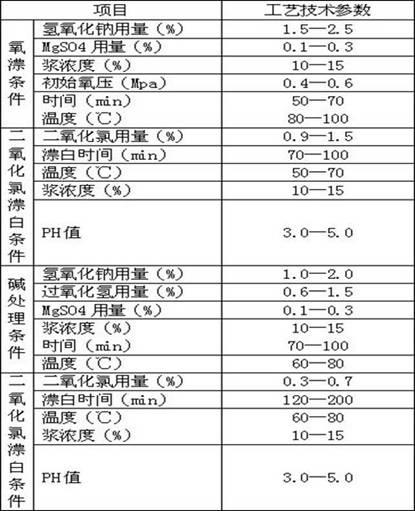

Image

Examples

Embodiment 1

[0020] A method for preparing industrial hemp whole stalk pulp, the method steps are as follows:

[0021] (1) Cut the air-dried hemp stalks into small pieces with a length of 10 mm to 30 mm, put them in the retting pool for retting to remove part of the pectin and non-fibrous impurities, and send them to the cooking pot after dehydration;

[0022] (2) The kraft method is used to cook hemp stalks; specifically, caustic soda with 18% weight of hemp stalks and sulfide alkali with 3% weight of hemp stalks are used to cook hemp stalks with water; the liquid ratio during cooking is 1:3, and the heating curve It is: heating time 90min, holding time 120min, maximum temperature 155°C; after cooking, a slurry is obtained;

[0023] (3) After the pulp is washed, it enters the beating unit. The beating unit is a conical refining unit. The beating concentration is controlled at 2%, and the beating degree is ≤40. o SR, fiber wet weight 5.0g; after beating, screen, purify, dehydrate, wash, s...

Embodiment 2

[0025] A method for preparing industrial hemp whole stalk pulp, the method steps are as follows:

[0026] (1) Cut the air-dried hemp stalks into small pieces with a length of 10 mm to 30 mm, put them in the retting pool for retting to remove part of the pectin and non-fibrous impurities, and send them to the cooking pot after dehydration;

[0027] (2) Use the kraft method to cook cannabis stalks; specifically, use caustic soda with 15% weight of hemp stalks and sulfide alkali with 5% weight of hemp stalks, then add water to cook hemp stalks; the liquid ratio during cooking is 1:2.5, and the heating curve It is: heating time 80min, holding time 150min, maximum temperature 150°C; after cooking, a slurry is obtained;

[0028] (3) After the pulp is washed, it enters the beating unit. The beating unit is a conical refining unit. The beating concentration is controlled at 4%, and the beating degree is ≤40. o SR, the fiber wet weight is 8.0g; after beating, it is screened, purified,...

Embodiment 3

[0030] A method for preparing industrial hemp whole stalk pulp, the method steps are as follows:

[0031] (1) Cut the air-dried hemp stalks into small pieces with a length of 10 mm to 30 mm, put them in the retting pool for retting to remove part of the pectin and non-fibrous impurities, and send them to the cooking pot after dehydration;

[0032] (2) Use the kraft method to cook cannabis stalks; specifically, use caustic soda with 22% weight of hemp stalks and sulfide alkali with 2% weight of hemp stalks and add water to cook hemp stalks; the liquid ratio during cooking is 1:4.5, and the heating curve It is: the heating time is 120min, the holding time is 100min, and the highest temperature is 165°C; after cooking, a slurry is obtained;

[0033] (3) After the pulp is washed, it enters the beating unit. The beating unit is a disc refining unit. The beating concentration is controlled at 3%, and the beating degree is ≤40. o SR, the wet weight of fiber is 4.0g; after beating, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com