Constructing method for mining embedded artificial boundary ore pillar from open-pit to underground mine

A technology of open-pit to underground and construction method, which is applied in the field of construction of embedded artificial boundary pillars in open-pit to underground mining, which can solve problems such as hidden safety hazards, deterioration of operating conditions, and air leakage of underground ventilation systems, so as to ensure normal operation and airtight Excellent performance and improved maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

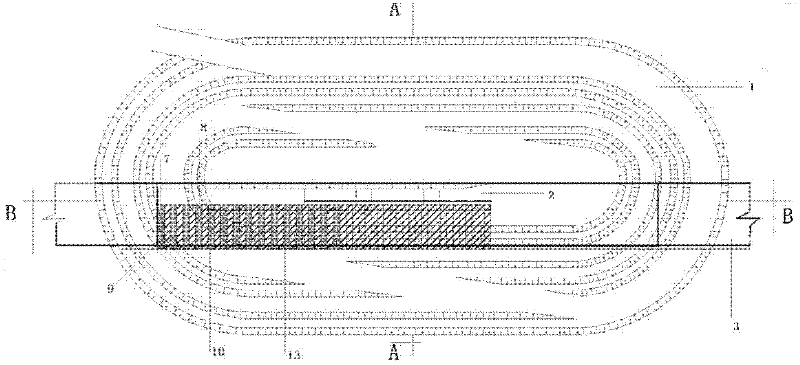

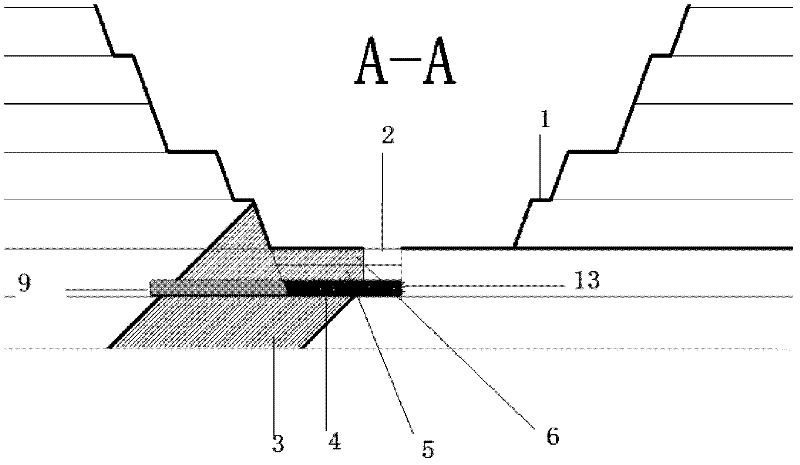

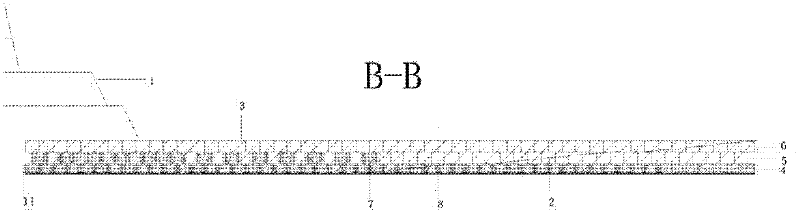

[0032] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0033] refer to Figure 1 to Figure 6 , In this embodiment, the method for constructing an embedded artificial boundary ore pillar from open-pit to underground mining in a gold mine, the construction steps are as follows:

[0034] (1) First excavate the trench 2 from the bottom elevation of the open pit 1, and the trench is set at the junction of the pit bottom ore body 3 and the surrounding rock. The footwall of the ore body is pulled apart and pushed to the toe of the side slope.

[0035](2) The ore body in the pit is divided into three layers from bottom to top (the first layered approach 4, the second layered approach 5 and the third layered approach 6) by using the upward approach filling mining method. Mining, the mining approach is arranged vertically to the ore body, the width of the mining approach is 4m, the first stratification app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com