Preparation method of graphite olefince modified electrochemical sensor electrode

A sensor electrode and graphene technology, which is applied in the field of preparation of graphene-modified electrochemical sensor electrodes, can solve the problems of not preparing electrochemical sensors and achieve high sensitivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with implementation.

[0013] A kind of preparation method of graphene modified electrochemical sensor electrode, its steps are as follows:

[0014] (1) The synthesized graphene oxide (GO) is dispersed in water to form an aqueous solution with a concentration of 0.125 mg / mL;

[0015] (2) The pure glassy carbon (GC) electrode was first polished with 0.3 μm aluminum powder, then washed with deionized water twice, and then ultrasonicated in ethanol, acetone and water for 5 minutes;

[0016] (3) 10 μL GO solution was dropped on the surface of the GC electrode, and then the electrode was dried at room temperature to obtain a graphene oxide-modified glassy carbon electrode, which was labeled as GO / GC electrode;

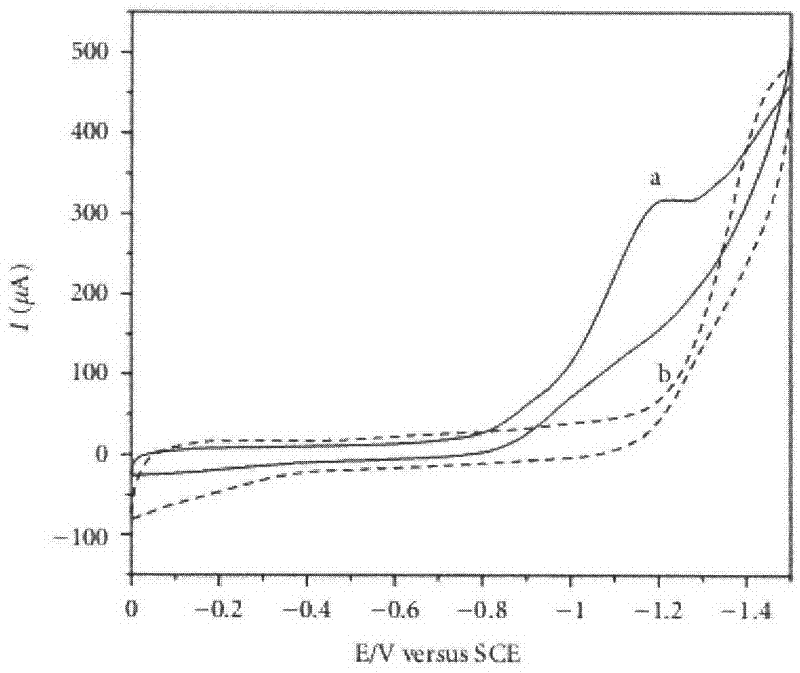

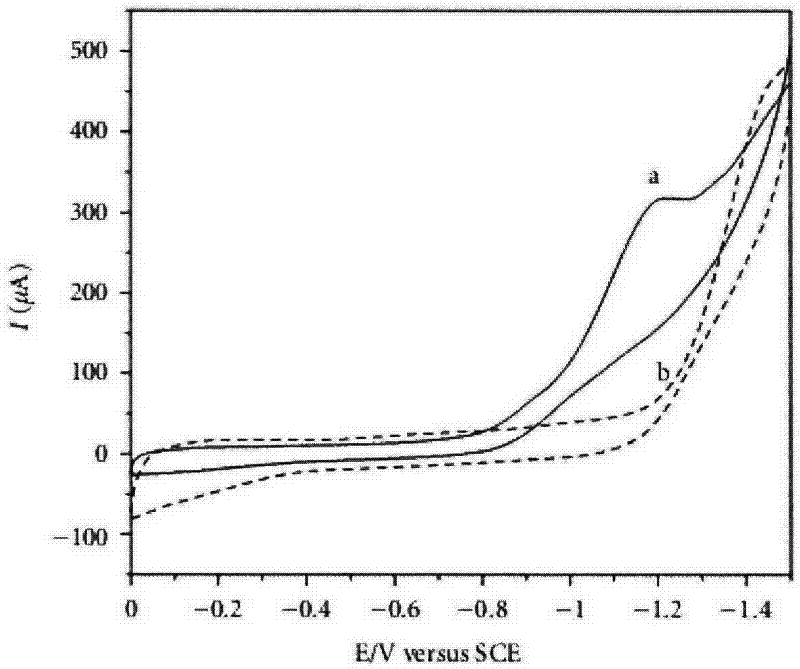

[0017] (4) Immerse the GO / GC electrode in 10mmol / L phosphate buffer solution with a pH value of 5, and then perform 5 cyclic potential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com