Tool holder, and tool system comprising a tool holder and a tool

A tool holder and cutting tool technology, which is applied to the accessories of tool holders, tools for milling machines, tools for lathes, etc., can solve problems such as insufficient guidance and unsatisfactory machining results, and achieve clamping savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

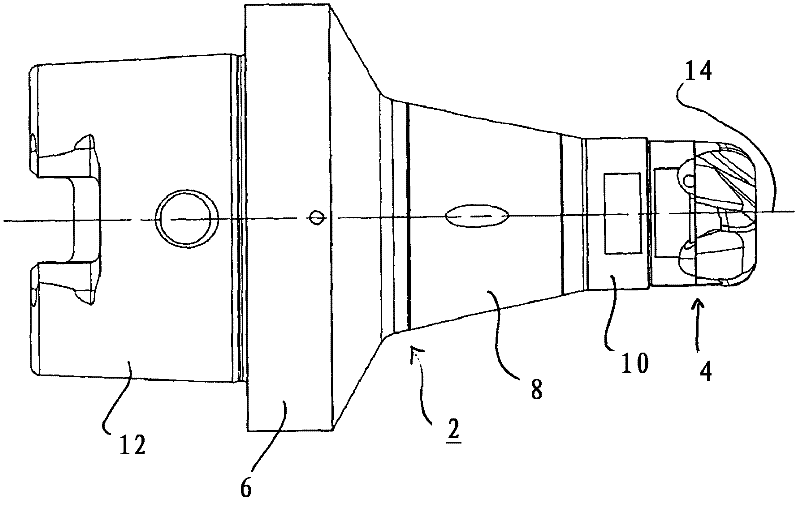

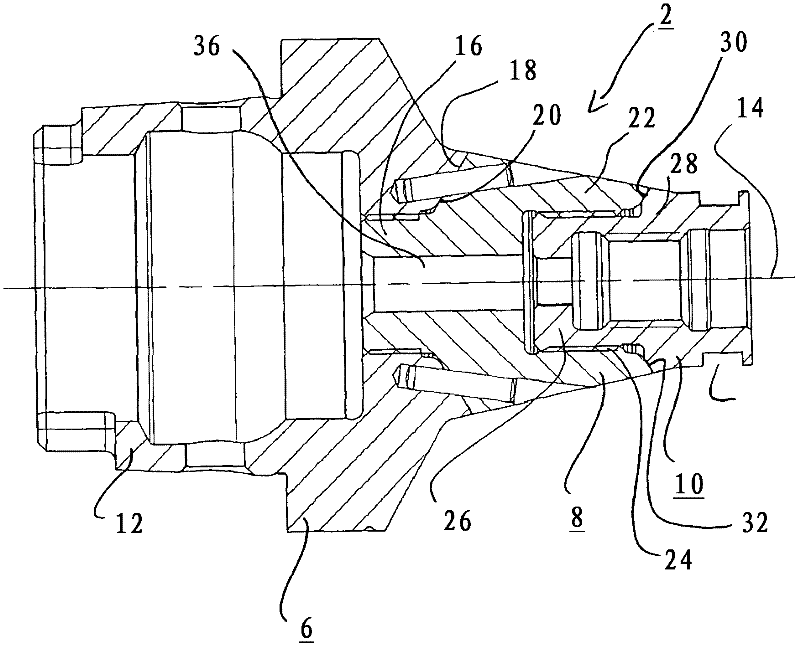

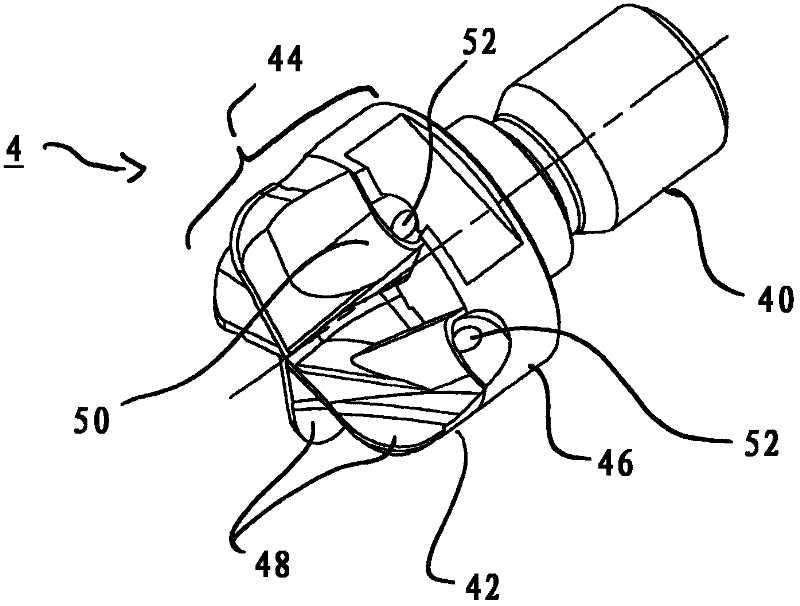

[0034] Will figure 1 and 2Tool holder 2 shown in, specifically with image 3 used in combination with special ball shank milling cutters shown in , for metal removal machining, in particular in the automotive sector for the production of ball races to enable an articulated wheel suspension. The tool holder 2 and the ball milling cutter 4 thus form a tool system, one of which is matched to the other.

[0035] The products in this case are mass-produced products and require good machining quality with short machining times. During machining, high loads occur, which can cause vibrations that lead to permanent tool wear and also lower machining quality. Tool holder 2 described hereinafter, specifically with image 3 The combination of the ball shank milling cutter 4 shown in , makes it possible to achieve high machining quality with a longer service life than the systems currently in use.

[0036] In this case the tool holder 2 is realized in three parts and has a rear machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com