Hydrothermal preparation method for spinel type ferrite nanopowder

A nano-powder and spinel-type technology, which is applied in the field of hydrothermal preparation, can solve the problems of difficult control conditions, complicated process, high cost, etc., and achieve the effect of uniform size, good dispersion, and simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

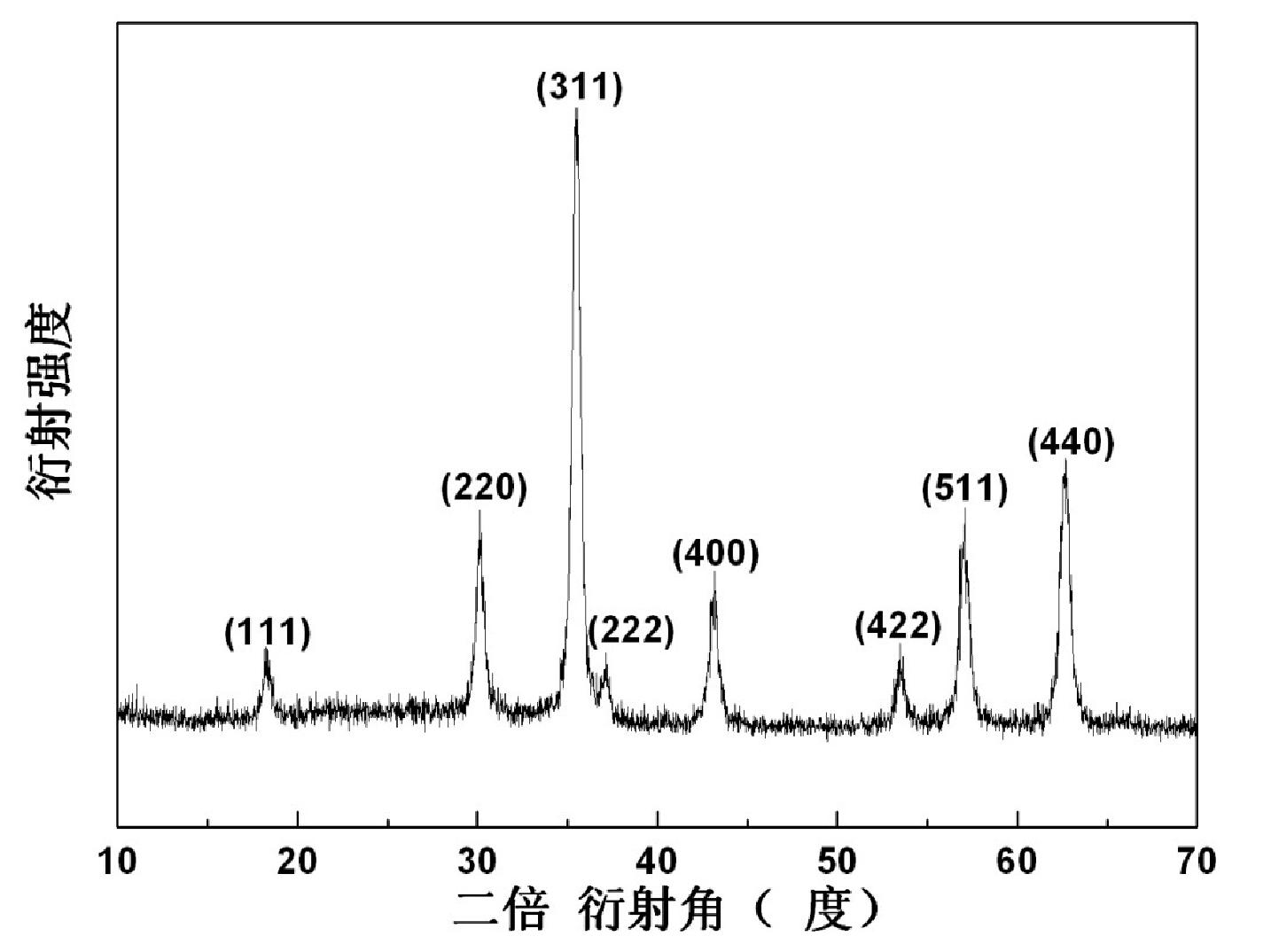

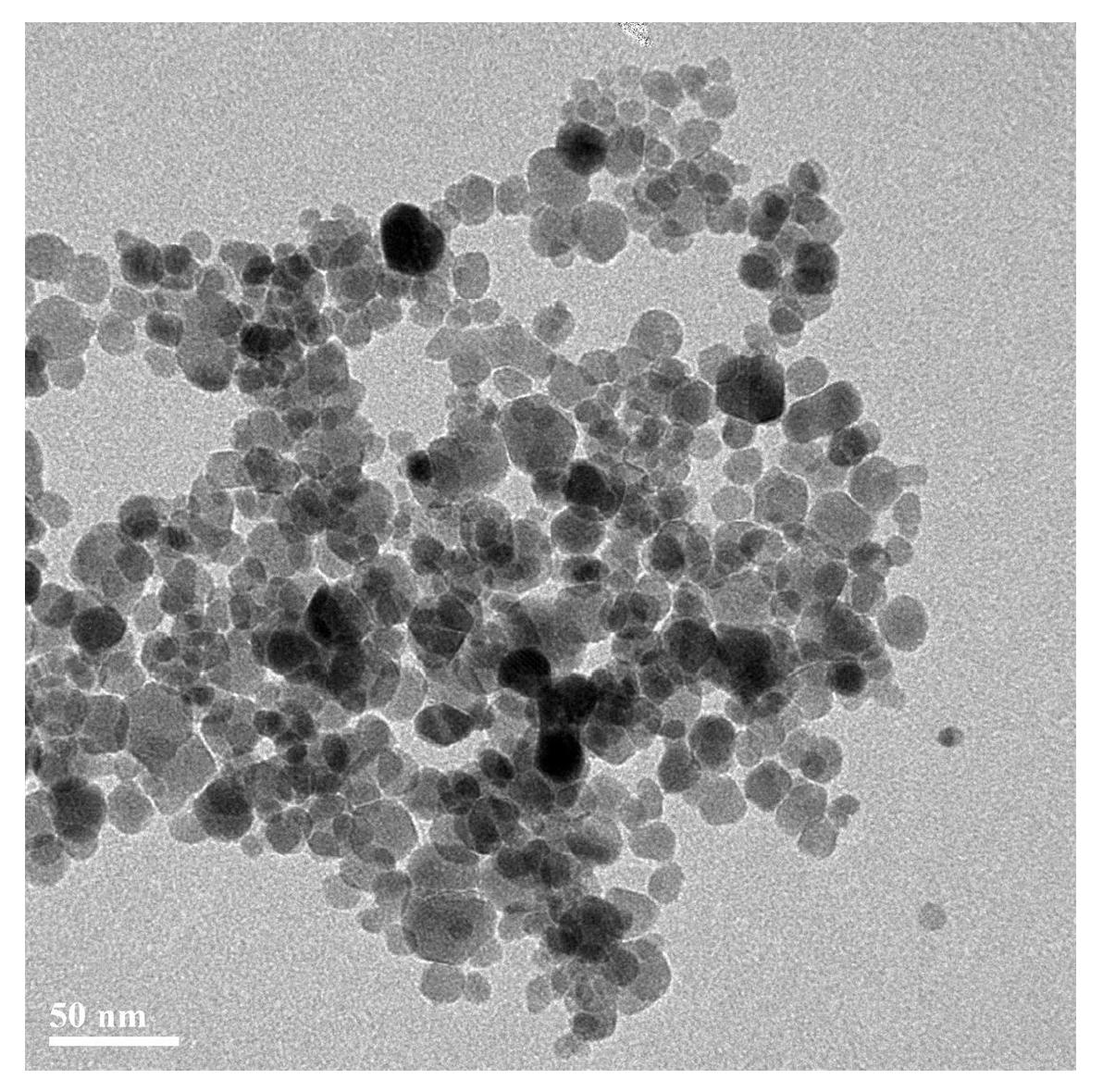

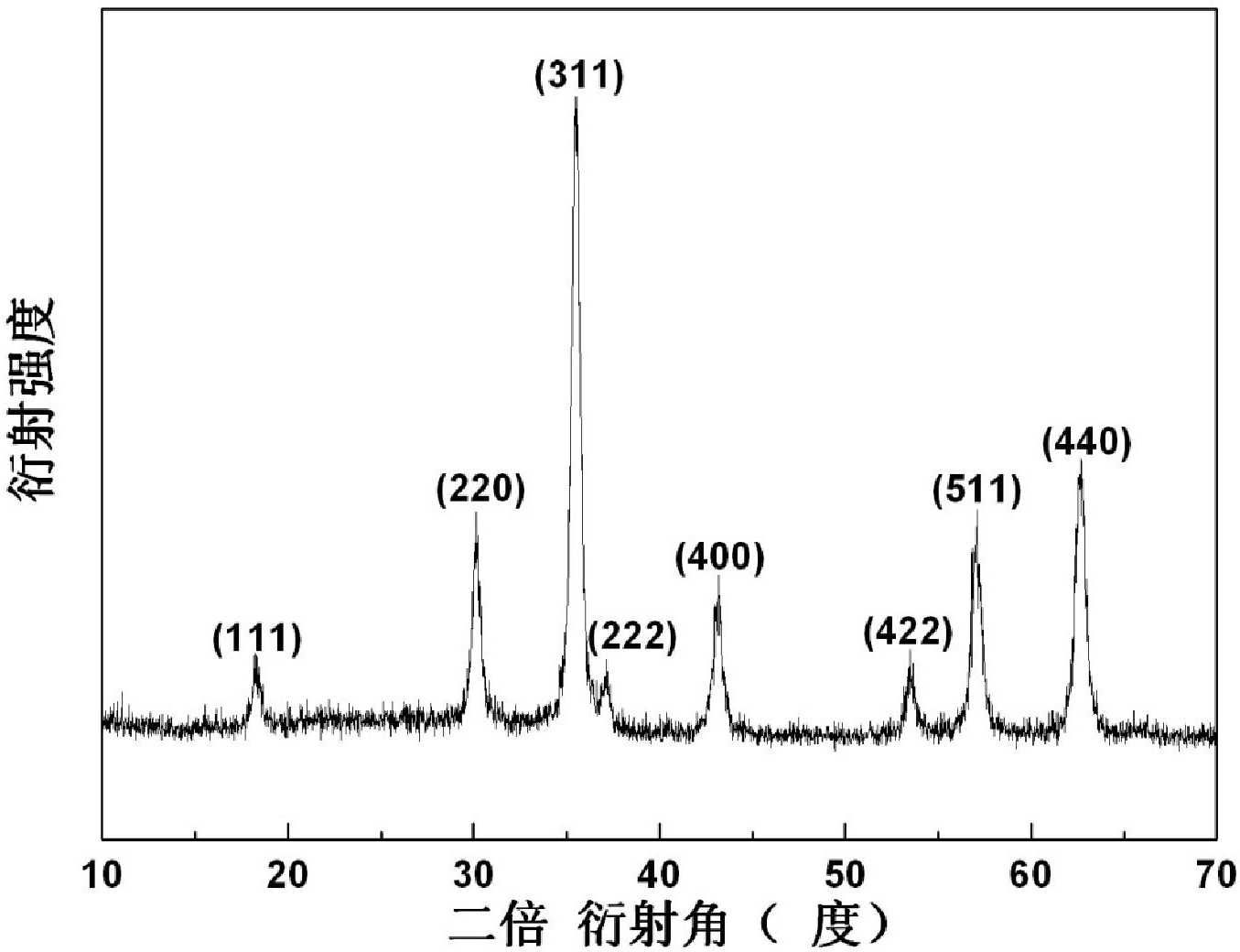

[0017] Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was completely dissolved in deionized water at a molar ratio of 1:2, and a brownish-red, transparent and stable solution was obtained. Then ethanolamine was added dropwise with constant stirring until complete precipitation. The obtained product was centrifuged three times with deionized water. Then add ammonia water, put the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 190°C for 6 hours, and centrifuge the product with deionized water for 3 times to obtain nano-ZnFe 2 o 4 .

Embodiment 2

[0019] Zn(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was completely dissolved in deionized water at a molar ratio of 1:2, and a brownish-red, transparent and stable solution was obtained. Then ethanolamine was added dropwise with constant stirring until complete precipitation. The obtained product was centrifuged three times with deionized water. Then add ammonia water, put the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 200°C for 6 hours, and centrifuge the product with deionized water for 3 times to obtain nano-ZnFe 2 o 4 .

Embodiment 3

[0021] Will Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was completely dissolved in deionized water at a molar ratio of 1:2, and a brownish-red, transparent and stable solution was obtained. Then ethanolamine was added dropwise with constant stirring until complete precipitation. The obtained product was centrifuged three times with deionized water. Then add ammonia water, put the mixture into a stainless steel reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 190°C for 6 hours, and centrifuge the product with deionized water for 3 times to obtain nano-CoFe 2 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com