Method for preparing copper polysaccharide through radial flow coupling ultra-filtering separation

A copper algae polysaccharide, ultrafiltration separation technology, applied in the preparation of tobacco, tobacco, food science, etc., can solve the problems of failing to meet the requirements of tobacco additives, complicated separation and purification steps, and short processing time, and achieve good application prospects , fast separation and purification speed, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

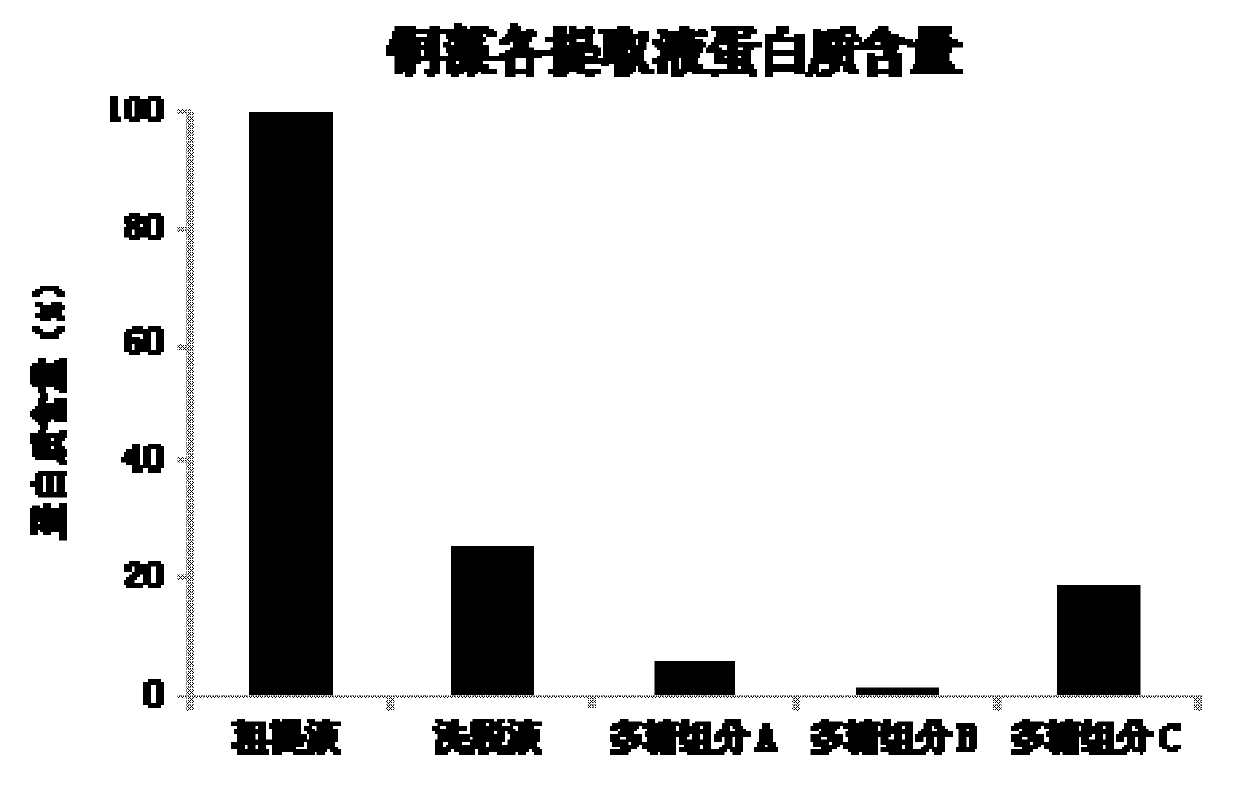

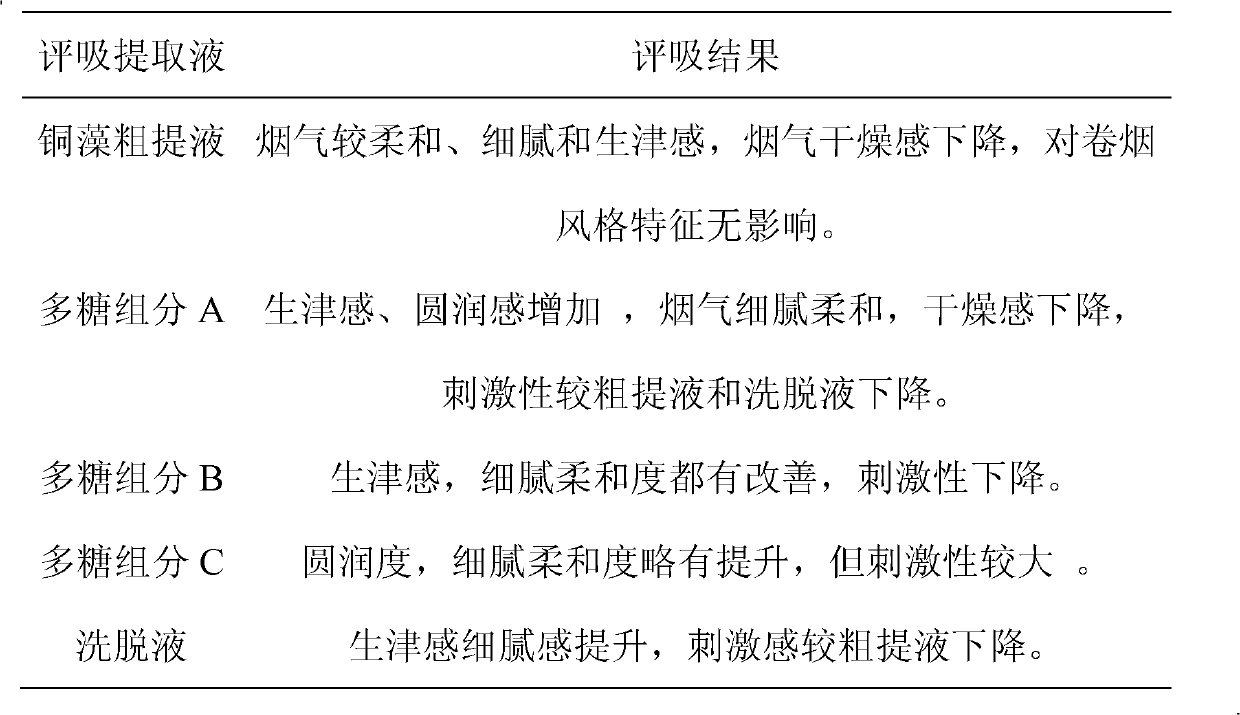

[0024] Take fresh copper algae, wash it and dry it in the shade, then put it in an oven to dry at 60°C, crush it to 20-100 mesh, add 50g of copper algae powder and 3L distilled water to extract under 400W ultrasonic conditions for 30min, and the extract is passed through 10000r / min high-speed centrifugation, after the supernatant was suction-filtered, the filtrate was concentrated and freeze-dried to obtain 7.12g copper algae crude polysaccharide. Take 0.5 g of copper algae crude polysaccharide to prepare 100 ml of copper algae crude extract with a concentration of 5 mg / ml, and use radial flow chromatography to remove the protein in the crude extract. The radial flow chromatography used is the model SUPERFLO-250COLUMN of Sepragen, USA The radial flow chromatographic column has a column volume of 250ml, an inner diameter of 1.5cm and an outer diameter of 7.8cm, a column height of 5cm, and is packed with A103S filler. The conditions of radial flow chromatography are: sample load...

Embodiment 2

[0034]Take fresh copper algae, wash it and dry it in the shade, then put it in an oven and dry it at 65°C, crush it to 20-100 mesh, add 50g of copper algae powder and 2.5L distilled water to extract under 500W ultrasonic conditions for 20min, the extract After high-speed centrifugation at 10,000 r / min, the supernatant was suction-filtered, and the filtrate was concentrated and freeze-dried to obtain 7.28 g of copper algae crude polysaccharide. Take 0.3g of copper algae crude polysaccharide to prepare 50ml of copper algae crude extract with a concentration of 6mg / ml, and use radial flow chromatography to remove the protein in the crude extract. The radial flow chromatography used is the model SUPERFLO-250COLUMN of Sepragen, USA The radial flow chromatographic column has a column volume of 250ml, an inner diameter of 1.5cm and an outer diameter of 7.8cm, a column height of 5cm, and is filled with A103S filler (what is the filler?). The conditions of radial flow chromatography ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com