Component analyzer for hydrocarbon gas mixture with oxygen compounds

A technology for compositional analysis and mixed gases, applied in the field of gas chromatograph analyzers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

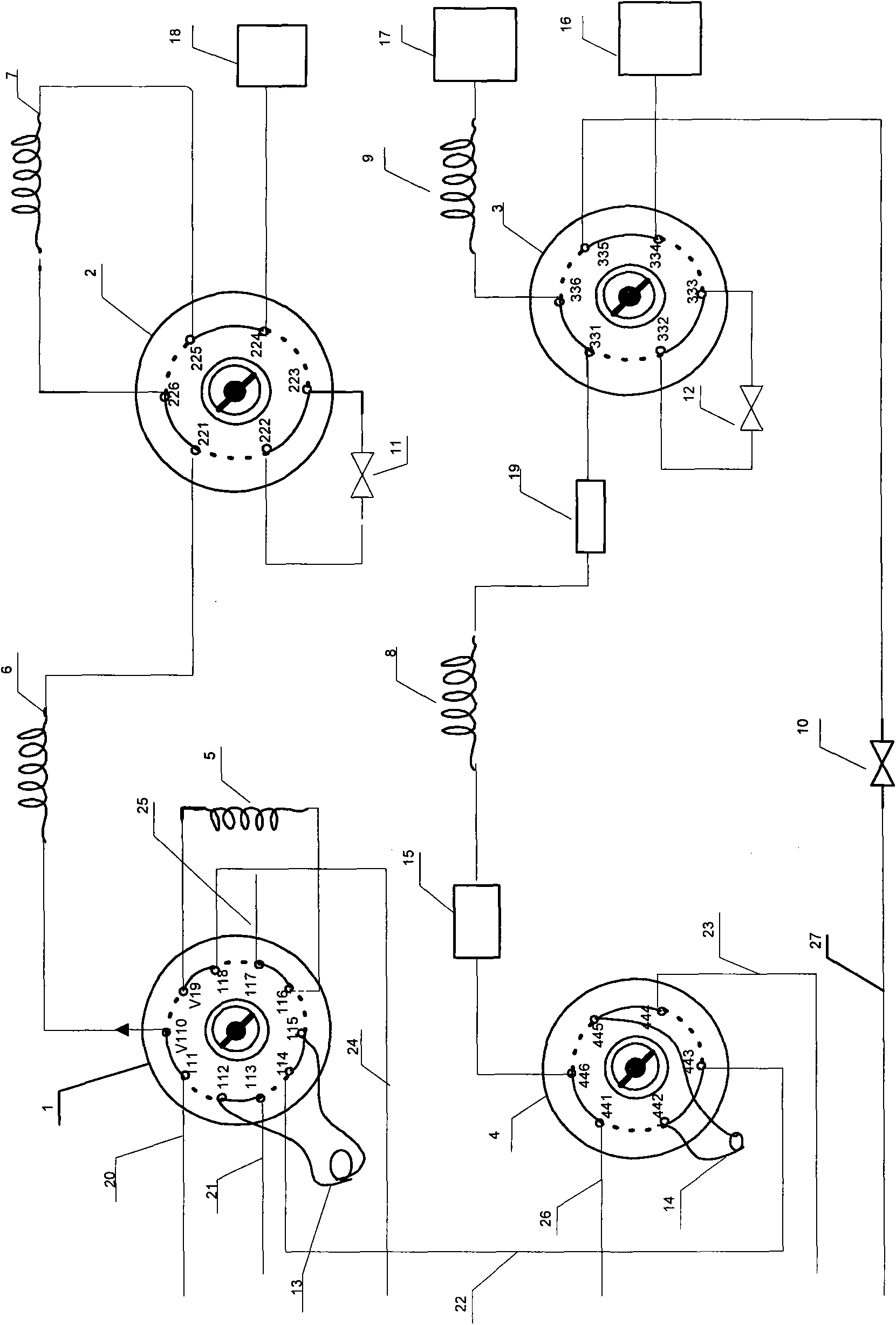

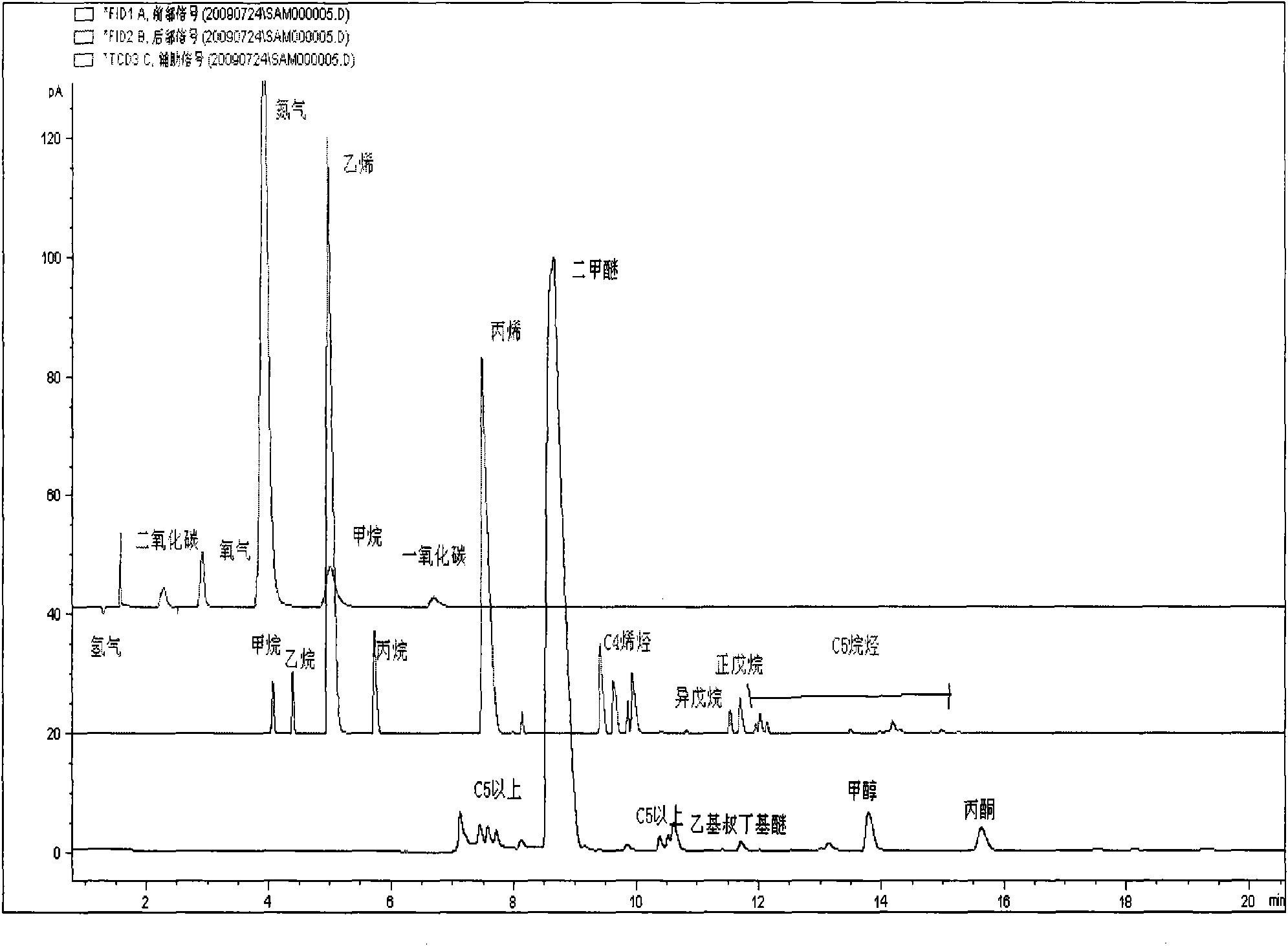

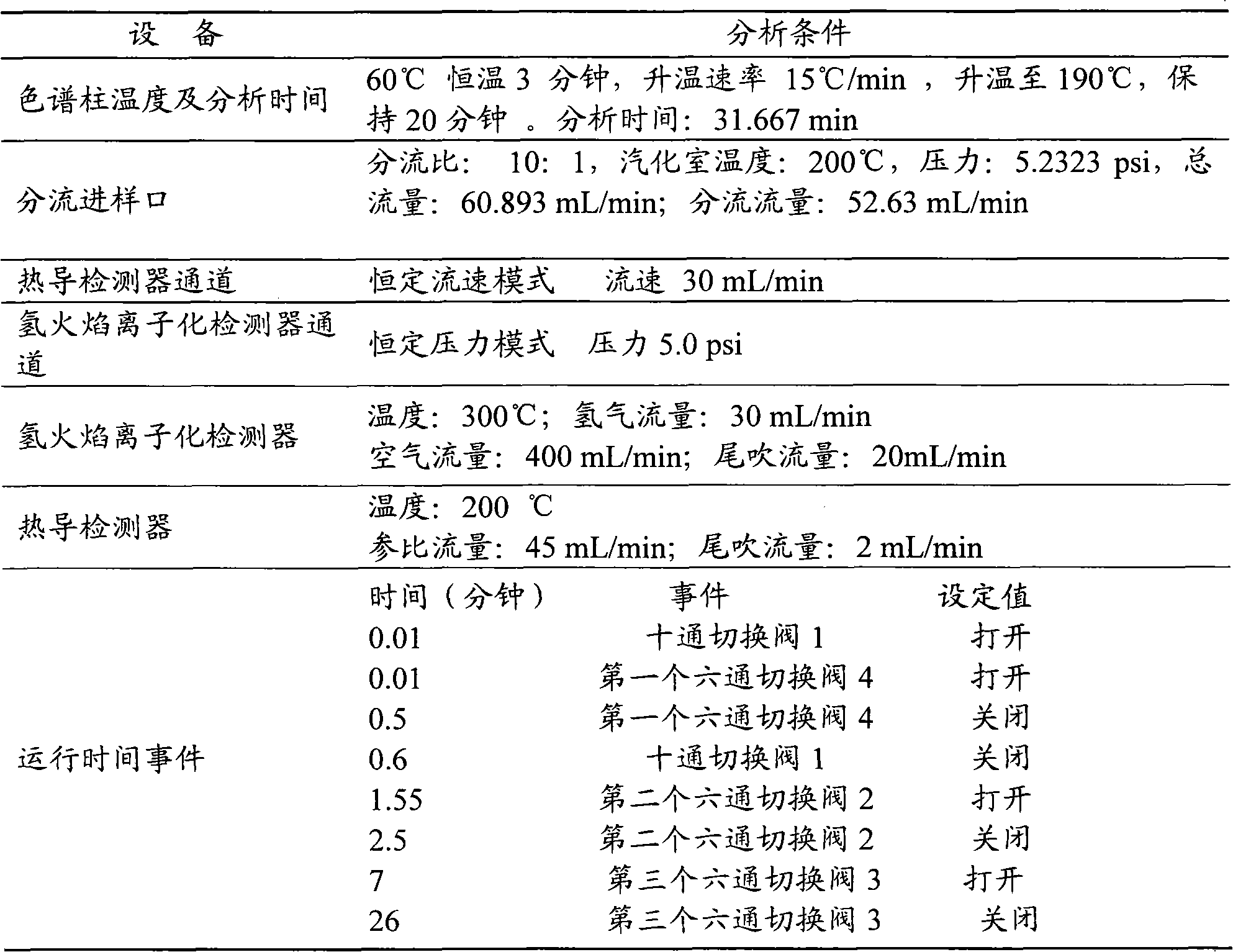

[0038] according to figure 1 Connect the column and detector, CO 2 The cutting column 5 selects PORAPAK Q packed column, the length of the column is 0.5 m, and the inner diameter of the column is 2 mm; 2 Separation column 6 selects PORAPAK Q packed column, column length 2 meters, column inner diameter 2 millimeters; Permanent gas separation column 7 selects 5A molecular sieve packed column, column length 2 meters, column inner diameter 2 millimeters; Polar capillary column 8 selects Agilent company to produce CP-LOWOX capillary column with a column length of 10 meters and an inner diameter of 0.53 mm; the hydrocarbon separation capillary column 9 is made of Al 2 o 3 Capillary column, column length 30 meters, column diameter 0.53 mm.

[0039] Ten-way switching valve 1 and CO 2 Cut column 5 and CO 2 The diameter of the interface of the separation column 6 is 1 / 8 inch; the connecting pipe between the interfaces is a 1 / 8 inch stainless steel pipe.

[0040] The diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com