Dry film photoresist containing special adhesive additive and plasticizer

A technology of photoresist and plasticizer, which is applied in the field of dry film photoresist developed by aqueous solution, and can solve the problems of negative impact of component adhesion, negative impact of exposure time and development time, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0050] The preparation of the adhesive used for photoresist, its formula is listed in Table 1.

[0051] Table 1

[0052]

[0053] 1: methylendenoic acid

[0054] 2: Methyl methacrylate

[0055] 3: Ethyl acrylate

[0056] 4: Isobornyl methacrylate

[0057] The synthesis of the binder is as follows. 422g of methyl ethyl ketone and 555g of the mixed monomers in Table 1 were added to a reaction vessel, and the reactants were stirred and heated to 80°C under nitrogen. Add 7ml azobisisobutyronitrile, butanone solution (concentration is 0.05g azobisisobutyronitrile / g butanone) in the reaction vessel, add 19ml azobisisobutyronitrile butanone solution (concentration (0.05g azobisisobutyronitrile / g butanone), continue stirring and heating for 1 hour, after the reaction is completed, the reactant is transferred to a glass container, and an appropriate amount of butanone is added to adjust the solid content to 31%.

[0058] The photoresist is prepared according to the components i...

Embodiment 5-8

[0074] Using the adhesives made in the formulations listed in Table 1, the photoresists were prepared in the formulations listed in Table 5.

[0075] table 5

[0076]

[0077]

[0078] 1. with the adhesive of embodiment 1

[0079] 2. with the adhesive of embodiment 2

[0080] 3. with the adhesive of embodiment 3

[0081] 4. with the adhesive of embodiment 4

[0082] 5.PUT polyurethane, see embodiment for preparation

[0083] *. Same as table 2 embodiment 1-4.

[0084] As described in Examples 1-4 above, the photoresist was pressed onto the copper foil substrate, exposed, developed, etched and tested, and the results are listed in Table 6.

[0085] Table 6

[0086] Example

Embodiment 9-13

[0088] The adhesives in Examples 9-13 were prepared according to the formulations in Table 7.

[0089] Table 7

[0090]

[0091] 1: Methacrylic acid

[0092] 2: Methyl methacrylate

[0093] 3: Ethyl acrylate

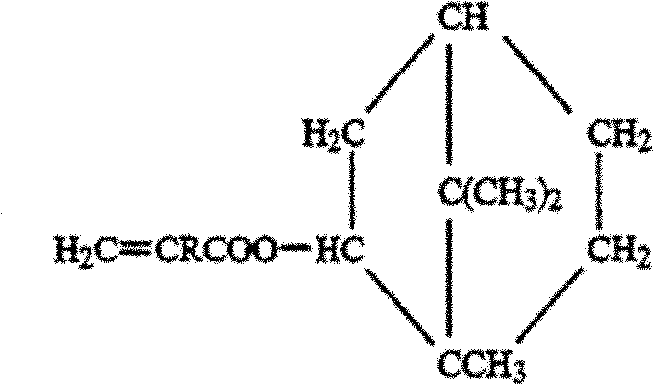

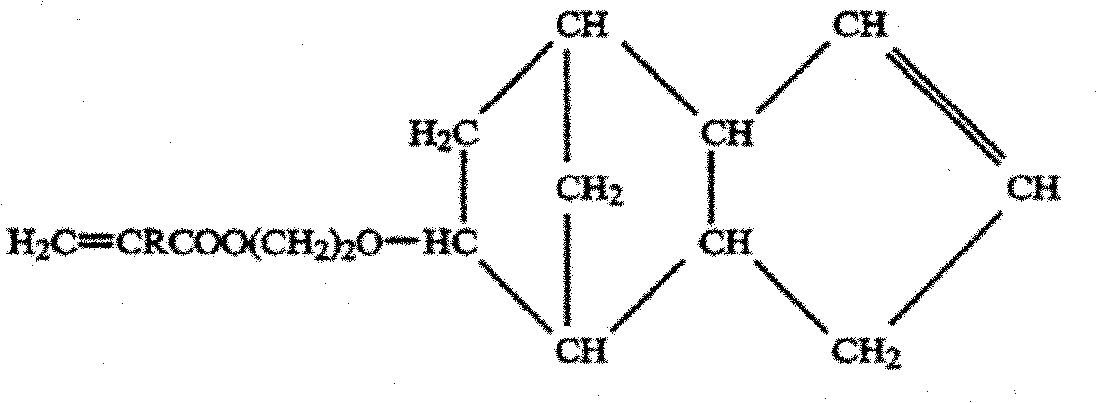

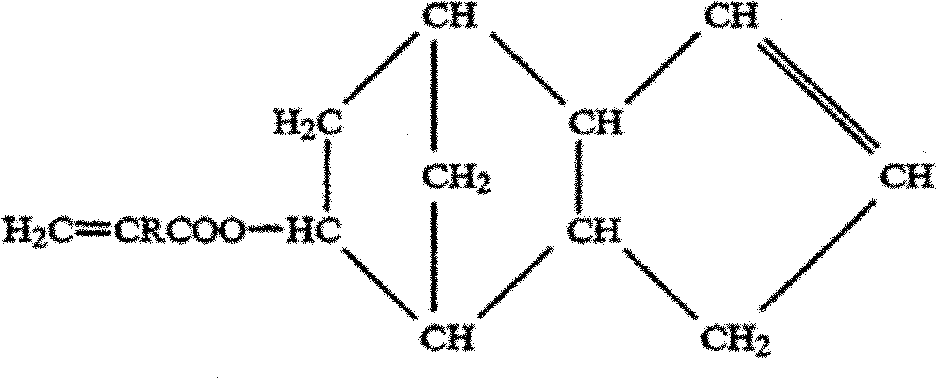

[0094] 4: Dicyclopentene oxymethacrylate

[0095] The photoresists of Examples 9-13 were prepared using the binders listed in Table 7 and the methods described in Examples 1-4.

[0096] Table 8

[0097]

[0098] *. Same as Embodiment 1-4

[0099] As described in Examples 1-4 above, the photoresist was pressed onto the copper foil substrate, exposed, developed, etched and tested, and the results are listed in Table 9.

[0100] Table 9

[0101] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com