Distributed feedback type organic semiconductor laser preparation method based on laser interferometer lithography

A laser interference lithography and distributed feedback technology, applied in the field of nanometer optoelectronic materials and devices, can solve the problems of complex process, expensive equipment, low efficiency, etc., and achieve the effects of good repeatability, high preparation efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Preparation of one-dimensional organic semiconductor nano-grating structure (one-dimensional structure)

[0019] 1) The recording medium S1805 photoresist is spin-coated on a glass substrate. The spin coating speed is 1800rpm, and the corresponding film thickness is 500nm;

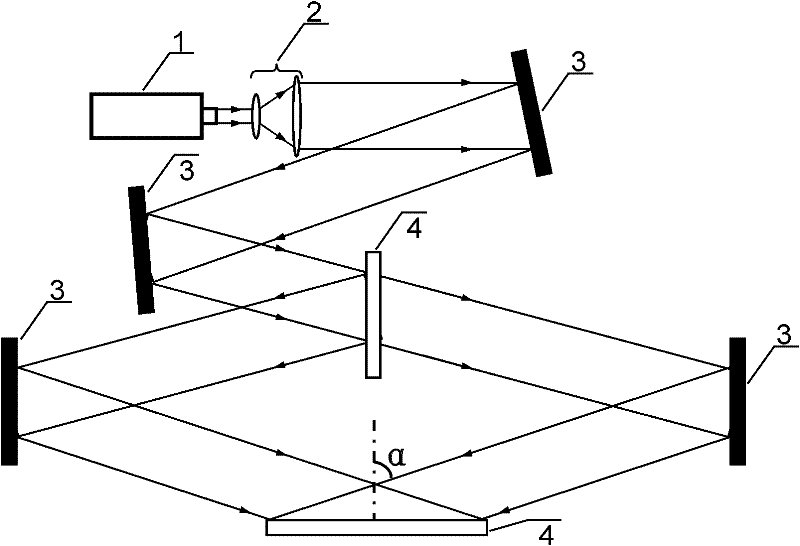

[0020] 2) Place the photoresist film sample prepared above in the interference optical path, such as figure 1 As shown, the angle between the two light beams α=22°, and the laser wavelength used for interference lithography is 355nm, the interference fringes can be recorded on the photoresist film, and then the photoresist sample is developed and fixed to obtain Periodic one-dimensional distributed feedback structure;

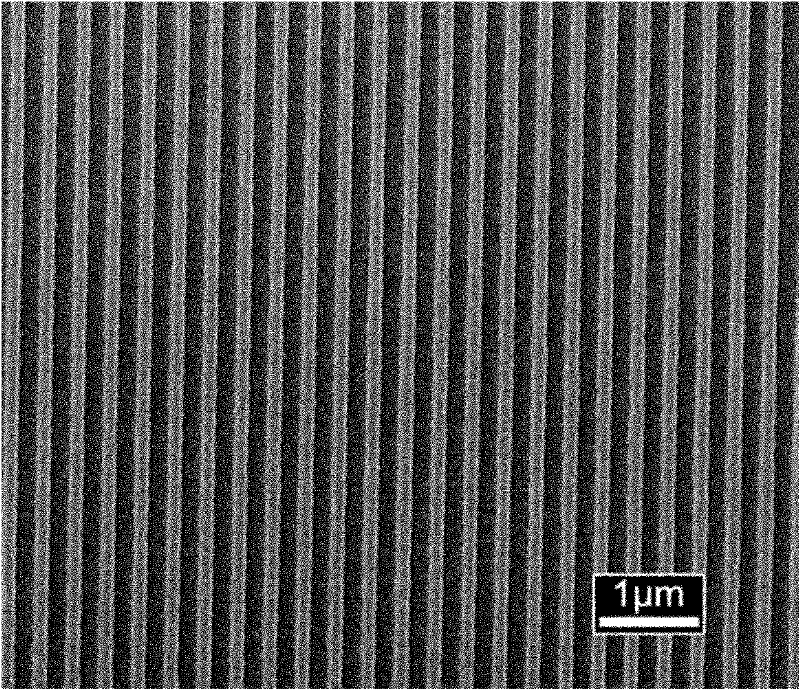

[0021] 3) The atomic force microscopy image of the prepared one-dimensional distributed feedback structure is as follows: figure 2 As shown, in the case of α=22°, the period of the prepared organic semiconductor grating is 355nm.

[0022] 4) Dissolving the organic ...

Embodiment 2

[0024] Embodiment 2: Preparation of two-dimensional distributed feedback structure (two-dimensional square structure)

[0025] On the basis of the one-dimensional distributed feedback structure preparation technology realized in Example 1, the sample is rotated 90° around its normal, and then the second interference exposure is performed to realize the preparation of the two-dimensional distributed feedback structure; and then The F8BT organic semiconductor solution is spin-coated on the distributed feedback structure of the recording medium to obtain a two-dimensional distributed feedback organic organic semiconductor laser.

Embodiment 3

[0026] Embodiment 3: Preparation of two-dimensional distributed feedback structure (two-dimensional triangular structure)

[0027] On the basis of the one-dimensional distributed feedback structure preparation technology realized in Example 1, the sample is rotated 60° around its normal, and then the second interference exposure is performed to realize the preparation of the two-dimensional distributed feedback structure; and then The F8BT organic semiconductor solution is spin-coated on the distributed feedback structure of the recording medium to obtain a two-dimensional distributed feedback organic organic semiconductor laser.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com