Mercury removal from cracked gas

A technology for copper sulfide and gaseous hydrocarbons, which is applied in the field of mercury removal, and can solve problems such as the difficulty of unsaturated hydrocarbon treatment and proof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

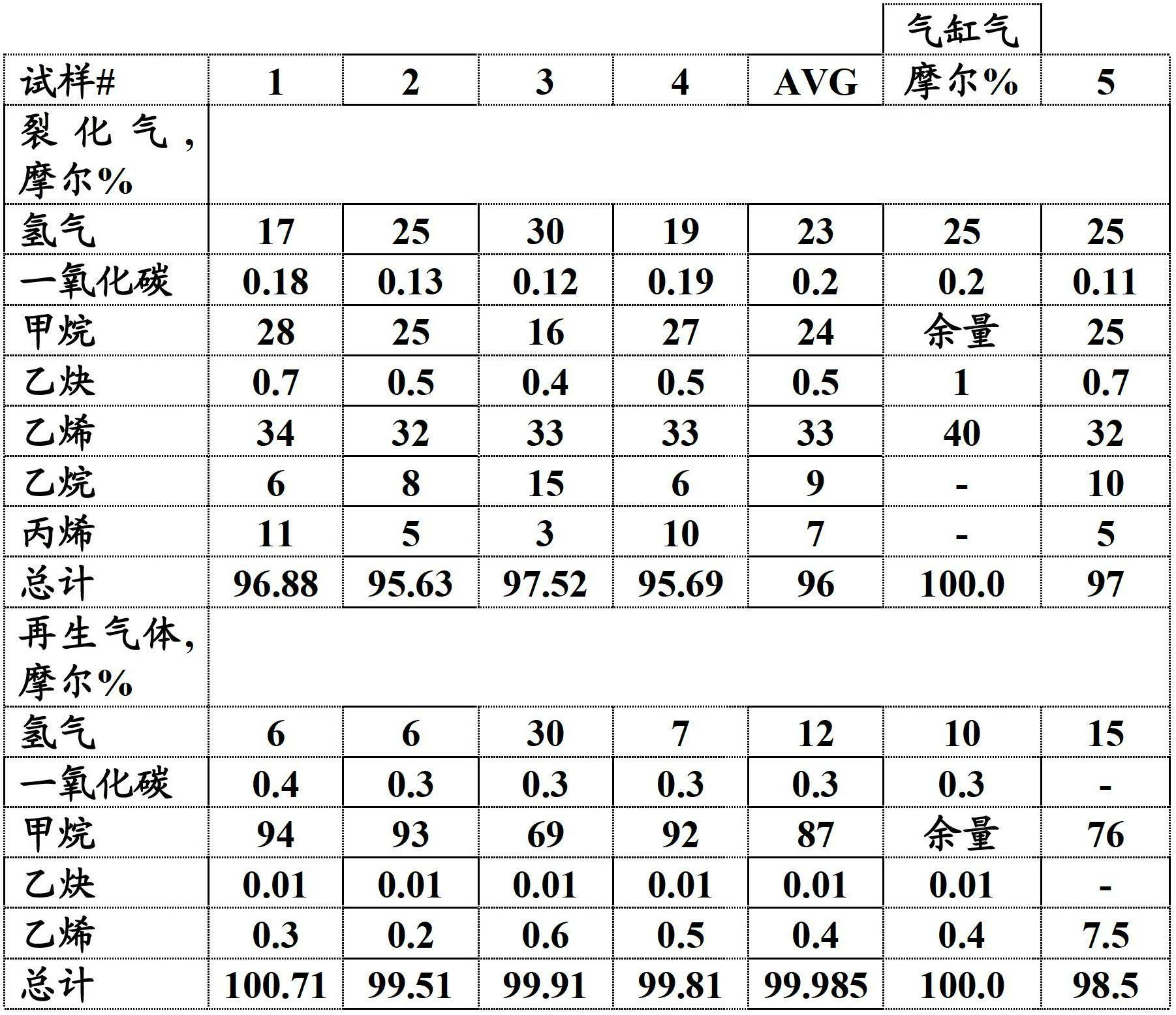

[0008] The present invention may be used to treat hydrocarbons comprising acetylene or acetylene series. Typically, 0.1% of said precursors may be present in the hydrocarbon to be treated. However, it is important to consider that any amount of alkyne may be a problem due to possible accumulation over time. The hydrocarbon stream may be from cracked gas or a stream cracked to produce ethylene.

[0009] Confirmation that materials prepared by co-forming porous basic copper carbonate and alumina powders, followed by heat treatment of the formed composite beads, followed by treatment with S to produce CuS-alumina composites do not have the tendency to form copper acetylides when treated with acetylene . Therefore, this material is suitable for use as a scavenger for mercury removal from cracked gas regeneration streams. The material is characterized by large crystals produced by coagglomeration. In addition, the CuS-alumina composite produced in the above manner has the resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com