Method for preparing liquefied natural gas from coke oven gas

A technology for liquefied natural gas and coke oven gas, applied in refrigeration and liquefaction, liquefaction, gas fuel and other directions, can solve the problems of high energy consumption of LNG products, complex liquefaction process, etc., and achieve convenient transportation and utilization, simple separation process, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

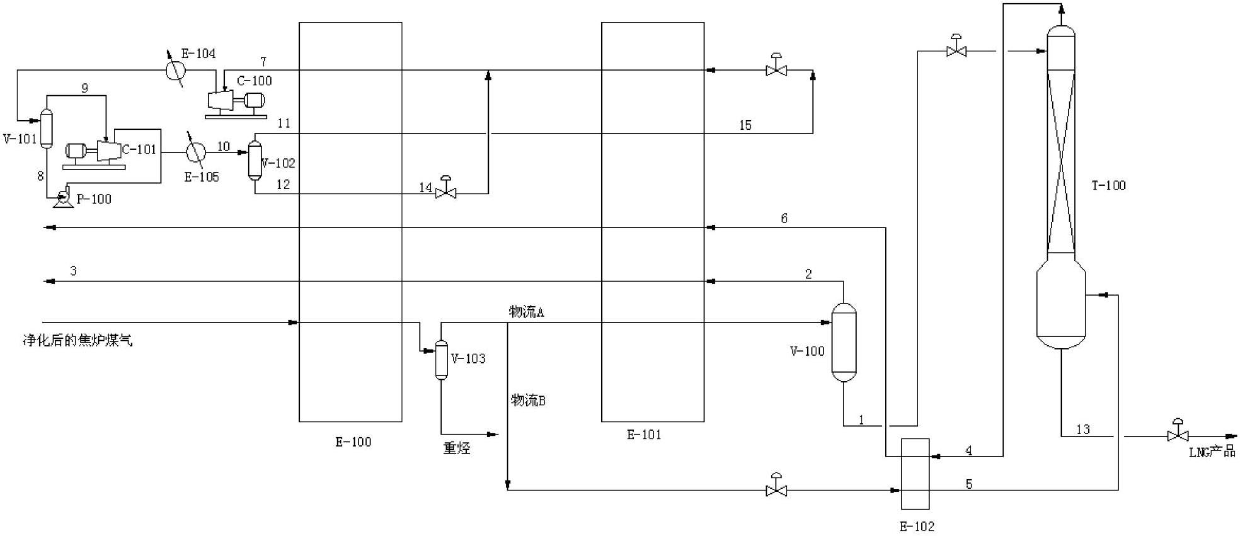

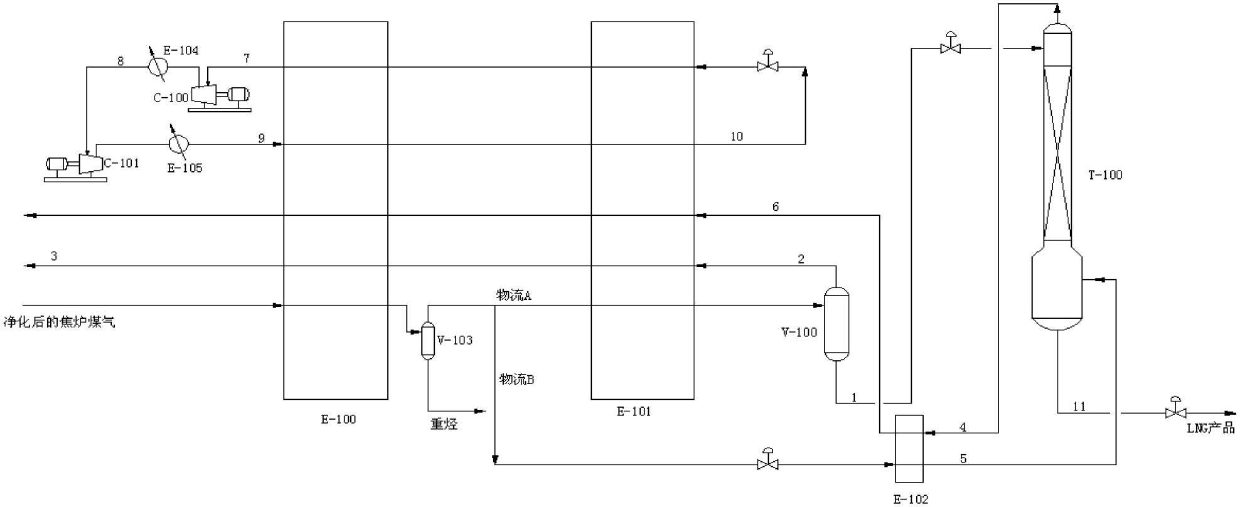

[0028] In this embodiment, LNG is produced by adopting two-stage throttling mixed refrigerant circulation and gas stripping method.

[0029] Such as figure 1 As shown, the process mainly includes a mixed refrigerant liquefaction system, coke oven gas cooling and hydrogen, nitrogen separation system; wherein the mixed refrigerant liquefaction system is a mixed refrigerant compression and throttling refrigeration system, which includes a mixed refrigerant compressor, Water cooler or air cooler, mixed refrigerant liquid pump, plate-fin heat exchanger; coke oven gas cooling and hydrogen, nitrogen separation system includes heavy hydrocarbon separation tank, gas-liquid separation tank and stripping tower, the stripping tower is not installed The reboiler and superheater simplify the structure of the tower, and control the purity of LNG by controlling the gas flow at the bottom of the stripping tower.

[0030] Its technological process is as follows:

[0031] Such as figure 1 Sho...

Embodiment 2

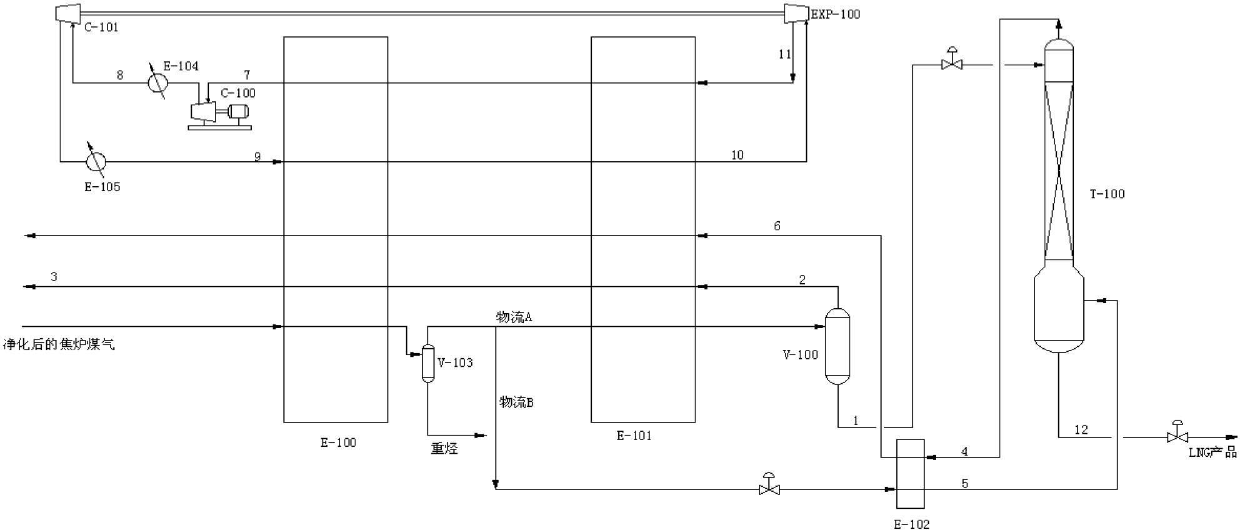

[0036] In this example, LNG is produced by nitrogen expansion refrigeration and gas stripping.

[0037] Such as image 3As shown, the process mainly includes nitrogen expansion refrigeration system, coke oven gas cooling and hydrogen, nitrogen separation system; wherein the nitrogen expansion refrigeration system is a nitrogen compressor, cooler, turbo expander, and coiled heat exchanger; The coke oven gas cooling and hydrogen and nitrogen separation system includes a heavy hydrocarbon separation tank, a gas-liquid separation tank and a stripping tower. The stripping tower is not equipped with a reboiler and superheater, which simplifies the tower structure. By controlling the gas flow at the bottom of the stripping tower, Control the purity of LNG.

[0038] Such as image 3 Shown: will contain H 2 , N 2 The qualified purified coke oven gas is cooled by the heat exchanger E-100, and enters the heavy hydrocarbon separation tank V-103 for heavy hydrocarbon separation; then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com