Movable automatic system and method for making curing formed product

A technology of solidification molding and products, which is applied in the field of automation systems, can solve the problems of difficult molding, water content that is not easy to burn, crushing, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

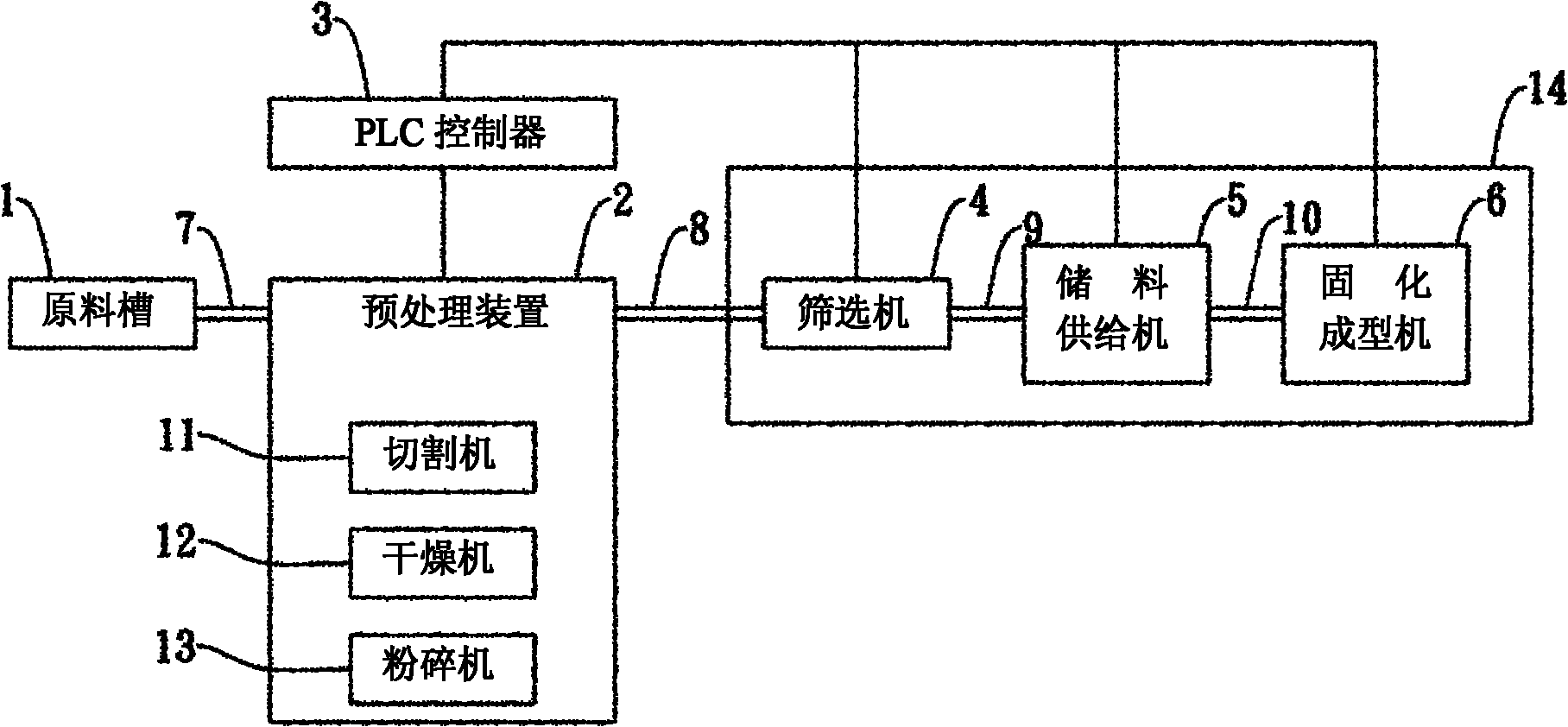

Method used

Image

Examples

Embodiment approach 1

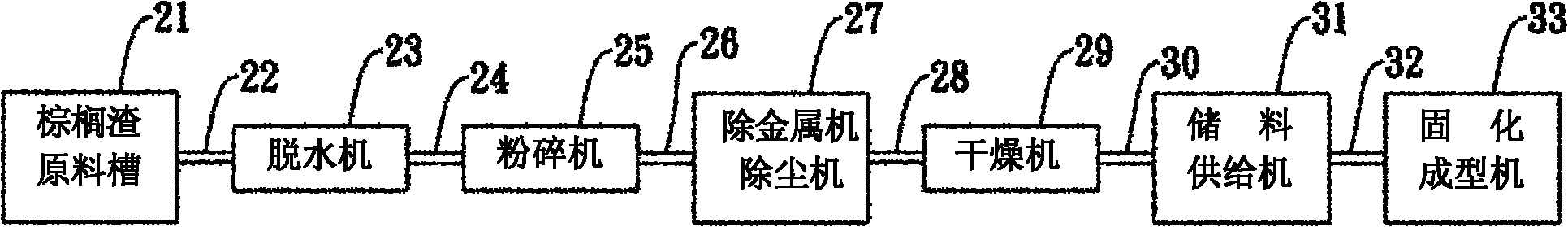

[0076] see figure 2, is a block diagram showing the first embodiment of the system for making cured moldings according to the present invention. In this embodiment, the raw material of "palm residue" is used to make the solidified molding. The palm slag in a palm slag raw material tank 21 is transported to a dehydrator 23 by a conveyor 22, and the palm slag is dehydrated to remove moisture by using the dehydrator 23. The dehydrated palm dregs are transported to a pulverizer 25 by a conveyor 24, and the dehydrated palm dregs are pulverized by the pulverizer 25. Then, the crushed palm slag is transported to a metal remover and dust remover 27 by a conveyor 26, and the metal remover and dust remover 27 are used to remove iron, metal, dust, sand and stones from the crushed palm slag. Afterwards, it is transported to a dryer 29 by a conveyor 28, and is dried by the dryer 29. The dried palm slag is transported to a storage feeder 31 by a conveyor 30 for storage first, and then t...

Embodiment approach 2

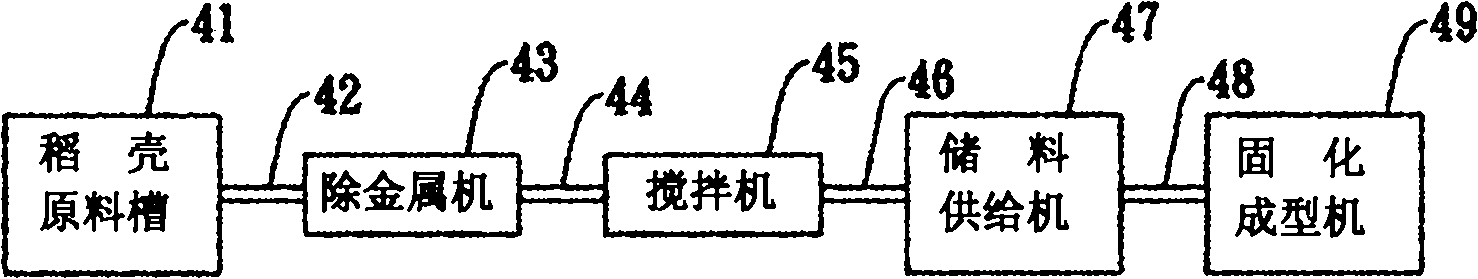

[0078] see image 3 , is a block diagram showing the second embodiment of the system for manufacturing biomass fuel solidified shaped rods according to the present invention. In this embodiment, the raw material of "rice husk" is used to make the solidified shaped stick of biomass fuel. The rice husk in a rice husk raw material tank 41 is transported to a metal removing machine by a conveyor 42, and the metal removing machine 43 is used to remove iron and metal from the rice husk. Afterwards, the rice husk after removing iron and metal is transported to a mixer 45 by a conveyor 44, and the rice husk is stirred and evenly regulated by the mixer 45. Then be transported to a storage feeder 47 by a conveyor 46 and store in advance, and then the rice husk stored in the storage feeder 47 will be delivered to a curing molding machine 49 by a certain amount of distribution conveyor 48, so that the rice husk Extruded into a biosolid.

[0079] The full-line production capacity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com