Preparation method of back electric-field silver paste of crystalline-silicon solar battery

A technology of solar cell and back electric field, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of usage restriction, environmental pollution, etc., and achieve the effect of meeting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention provides an environment-friendly crystalline silicon solar cell back electric field silver paste which can be used for screen printing. PBB, polybrominated diphenyl ether (PBDE) and EU RoHS Directive 2005 / 84 / EC on phthalates) are ideal substitutes for non-environmentally friendly (lead-containing) back-field silver pastes that are currently commonly used.

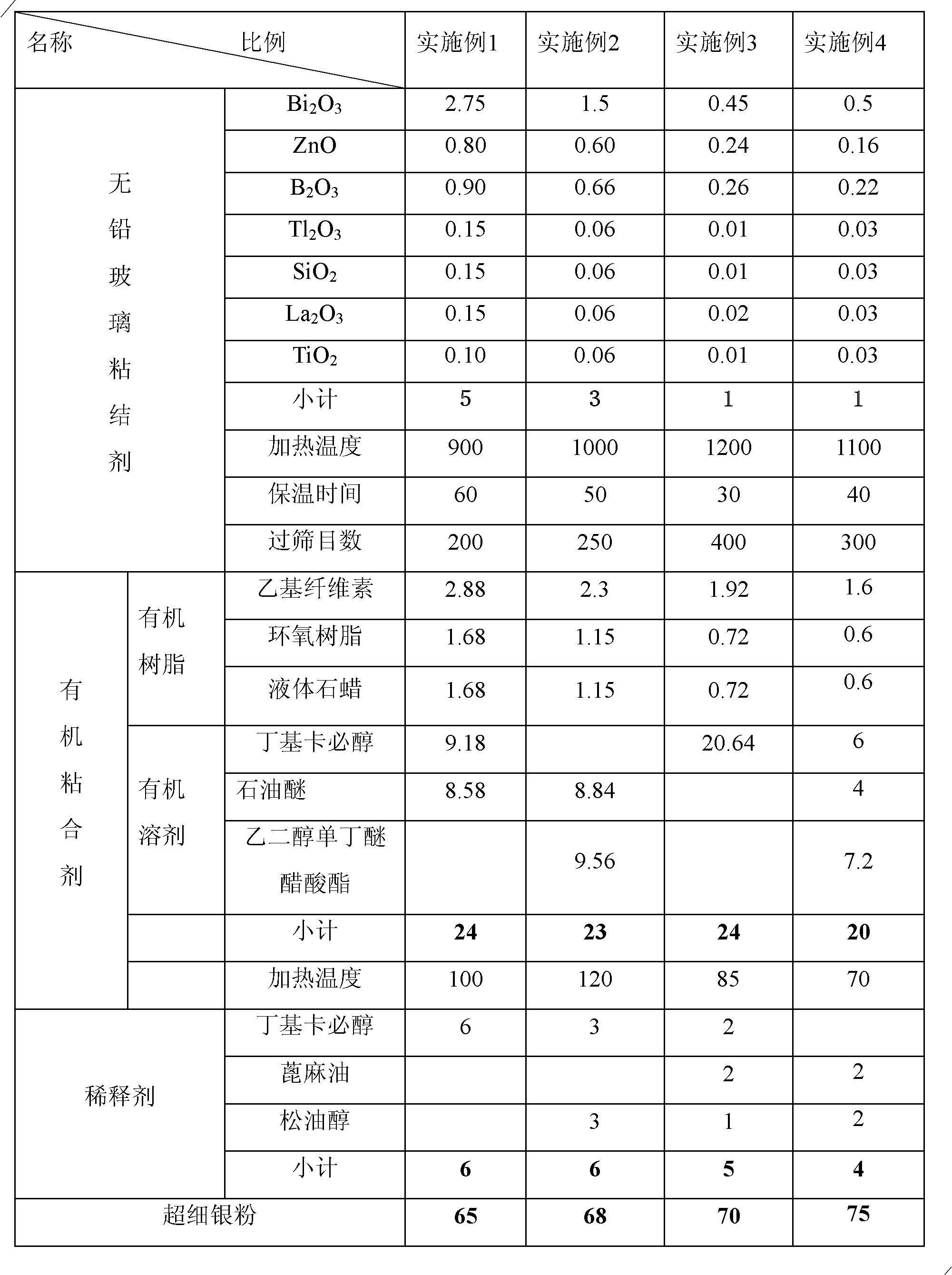

[0016] The specific technical scheme of the present invention is as follows: an environment-friendly crystalline silicon solar cell back electric field silver paste, comprising the following basic steps: Step A: preparation of lead-free glass binder: according to the raw material composition of lead-free glass binder and its Mass percentage weighing, ZnO 20-30%; B 2 o 3 20-25%; Tl 2 o 3 1-3%; SiO 2 1-3%; La 2 o 3 1-3%;TiO 2 1-3%; the balance is Bi 2 o 3 ; Introduce thallium oxide (Tl 2 o 3 ) and lanthanum oxide (La 2 o 3 ), which is used to reduce the glass transition temperature (Tg) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com