Supporting plate produced by waste textiles

A technology for waste textiles and raw materials, which is applied in the field of pallets produced by using waste textiles, can solve the problems of complex components and a large gap in advanced level, and achieve the effects of low price, saving storage and transportation space, and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

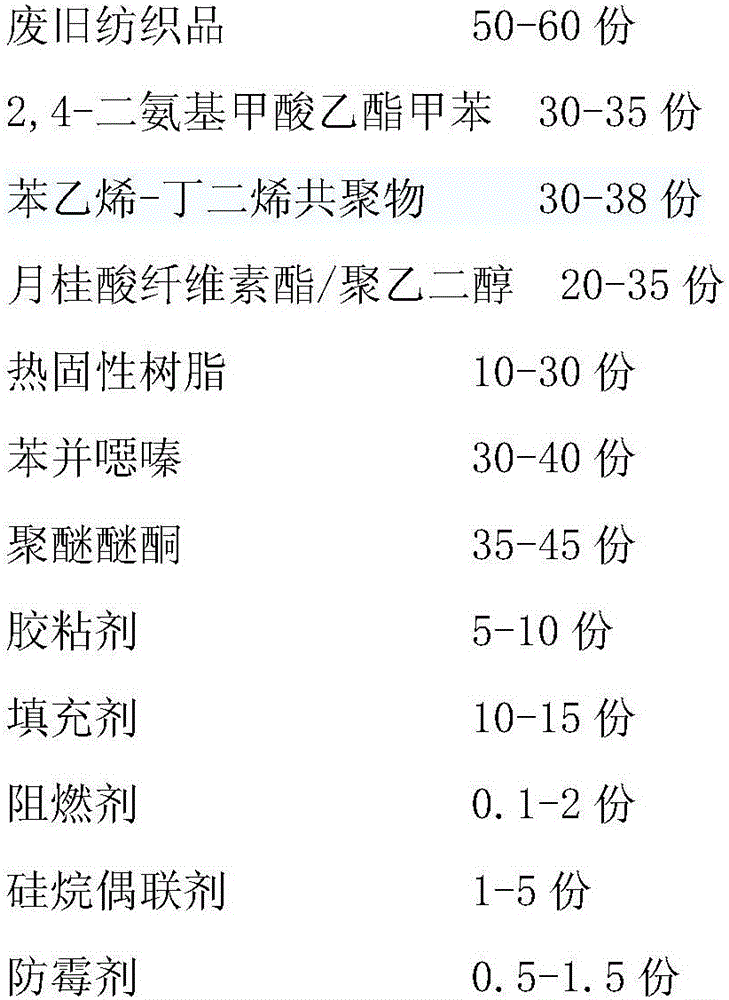

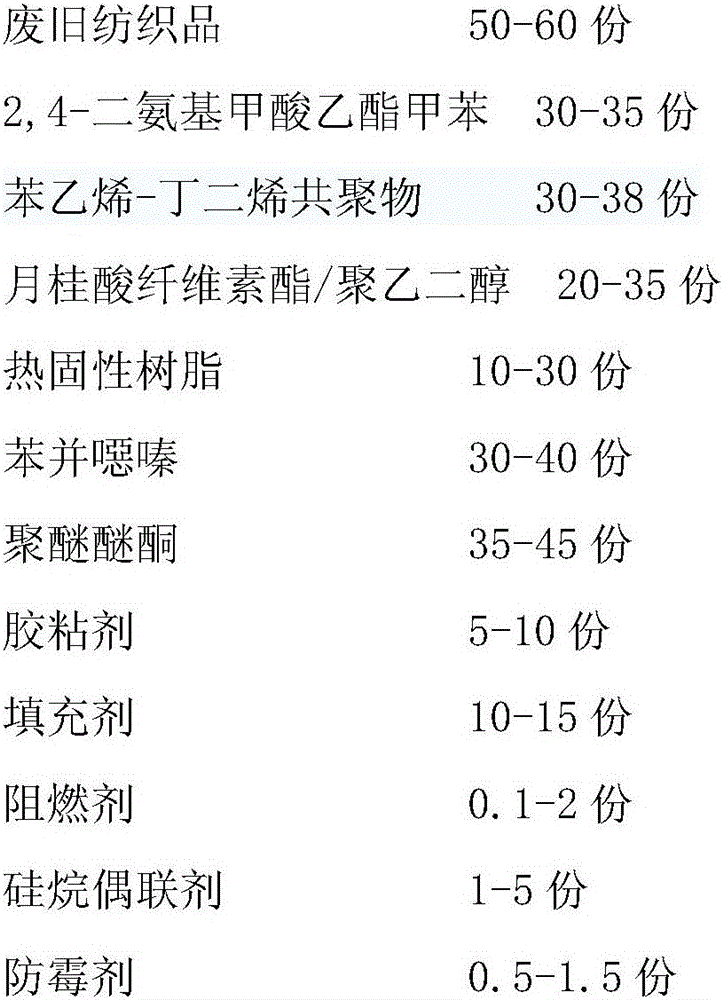

Method used

Image

Examples

Embodiment 1

[0030] The weight parts of raw materials are: 54 parts of waste textiles, 30 parts of 2,4-diurethane toluene, 30 parts of styrene-butadiene copolymer, 20 parts of cellulose laurate / polyethylene glycol, and 23 parts of thermosetting resin. Parts, 35 parts of benzoxazine, 40 parts of polyetheretherketone, 8 parts of liquid glue, 13 parts of alumina powder, 1 part of aluminum hydroxide, 3 parts of vinyl triethoxysilane, 1.0 part of phenol;

[0031] The preparation method is as follows:

[0032] First, raw material preparation: take the recycled waste textiles of the above weight parts as raw materials, send the raw materials into the washing tank for cleaning, dry them in the high-temperature disinfection equipment for disinfection, and send the disinfected raw materials to the special scrap mechanism to obtain waste Textile fiber fragments;

[0033] Second, raw material mixing: send waste textile fiber fragments into the mixer, where a glue injection port is provided in the mixer, and...

Embodiment 2

[0037] The weight parts of raw materials are: 50 parts of waste textiles, 31 parts of 2,4-diurethane toluene, 33 parts of styrene-butadiene copolymer, 25 parts of cellulose laurate / polyethylene glycol, and 10 parts of thermosetting resin Parts, 30 parts of benzoxazine, 35 parts of polyether ether ketone, 10 parts of powder glue, 15 parts of glass fiber and alumina powder, 2 parts of triphenyl phosphate and aluminum hydroxide, aminopropyl triethoxysilane 5 parts, 1.5 parts phenol;

[0038] The preparation method is as follows:

[0039] First, raw material preparation: take the recycled waste textiles of the above weight parts as raw materials, send the raw materials into the washing tank for cleaning, dry them in the high-temperature disinfection equipment for disinfection, and send the disinfected raw materials to the special scrap mechanism to obtain waste Textile fiber fragments;

[0040] Second, raw material mixing: send waste textile fiber fragments into the mixer, where a glue...

Embodiment 3

[0044] The weight parts of raw materials are: 54 parts of waste textiles, 32 parts of 2,4-diurethane toluene, 35 parts of styrene-butadiene copolymer, 28 parts of cellulose laurate / polyethylene glycol, and 16 parts of thermosetting resin Parts, 38 parts of benzoxazine, 38 parts of polyetheretherketone, 8 parts of liquid glue, 13 parts of alumina powder, 1 part of aluminum hydroxide, 3 parts of vinyl triethoxysilane, 1.0 part of phenol;

[0045] The preparation method is as follows:

[0046] First, raw material preparation: take the recycled waste textiles of the above weight parts as raw materials, send the raw materials into the washing tank for cleaning, dry them in the high-temperature disinfection equipment for disinfection, and send the disinfected raw materials to the special scrap mechanism to obtain waste Textile fiber fragments;

[0047] Secondly, raw material mixing: send waste textile fiber fragments into the mixer, where a glue injection port is provided in the mixer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com