Nano environment-friendly ultra-light painting light box fabric

An ultra-light, light box cloth technology, used in coatings, instruments, display devices, etc., can solve the problems of limited recycling and heavy quality, and achieve the effect of improving the flatness of the coating, fast drying, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

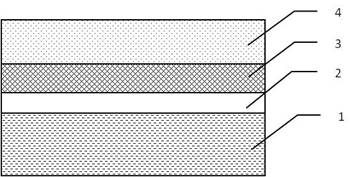

Image

Examples

Embodiment 1

[0018] ⑴Using high-density polyethylene plastic granules, drawing through a plastic flat wire drawing machine and weaving on a water-jet loom to obtain the base fabric;

[0019] (2) On the laminating machine, pour a layer of low-density polyethylene with a thickness of 0.025mm on the front of the base cloth to obtain a polyethylene base cloth;

[0020] (3) Preparation of ink-absorbing coating: add 0.8Kg A08 to 3.85Kg polyvinyl chloride emulsion, add 38.5 Kg nano-silica after stirring for 10 minutes, add ammonia water to adjust the pH value to 6-7 after dispersing for 30 minutes, add 5.5Kg pure acrylic emulsion After stirring for 10 minutes, add 5.5Kg of calcium carbonate, 0.55Kg of titanium dioxide, 0.1Kg of wetting agent TN-21, and then add 0.1Kg of whitening agent, 0.05Kg of n-butanol and 0.05Kg of sodium chloride after stirring for 40 minutes, and stir for 10 minutes Get after filtering;

[0021] ⑷Using printing gravure coating, the front of the polyethylene base cloth is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com