Production process of environment-friendly microwave ceramic copper-clad plate

A technology of microwave ceramics and production technology, which is applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of poor heat resistance, high difficulty, slow charging and discharging process, etc., and achieve excellent high frequency and low loss properties, best electrical and mechanical properties, effect of low thermal coefficient of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with specific embodiments.

[0016] A production process of environment-friendly microwave ceramic copper-clad laminates, which is to modify the surface of glass fiber cloth and then dip it into a prepreg in the synthetic slurry; after winding or cutting, laminating and anchoring copper foil; and then pre-cooling Pressing; finally, under the vacuum condition of 10-20Kpa, pressurize and solidify for 1-2 hours in a hot press with a temperature of 350-400°C and a pressure of 15-20Mpa; according to the raw material composition and ratio and the above-mentioned manufacturing method The implementation is described below.

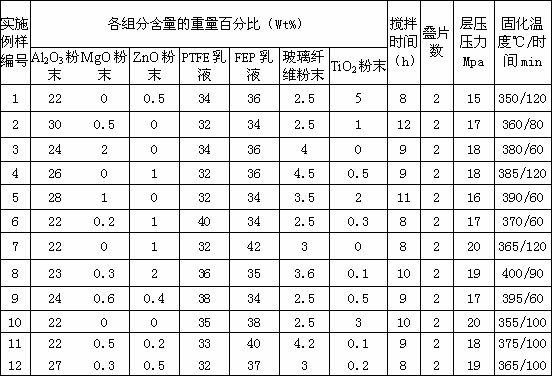

[0017] Table 1 provides the data of each embodiment sample raw material and production parameters:

[0018]

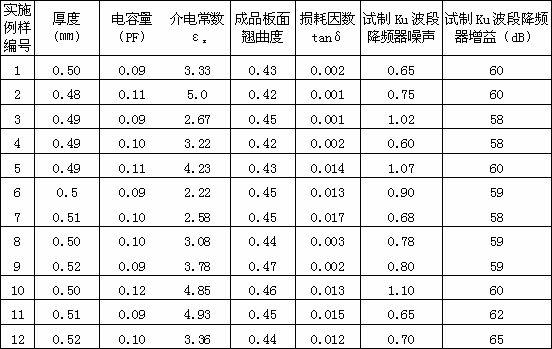

[0019] Table 2 provides the performance of each embodiment sample:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com