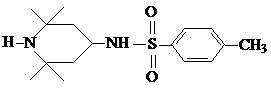

Method for preparing light stabilizer 4-p-toluenesulfonamide-2,2,6,6-tetramentylniperidine

A technology of toluenesulfonamido and tetramethylpiperidine is applied in the field of preparation of light stabilizer 4-p-toluenesulfonamido-2,2,6,6-tetramethylpiperidine, and achieves low environmental pollution, The effect of high product yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 250mL four-necked flask, add 60g of solvent, 15.6g of 4-amino-2,2,6,6-tetramethylpiperidine, 14.3g of catalyst, and 24.8g of p-toluenesulfonyl chloride, and reflux and condense Tube, thermometer, start the agitator, control the temperature at 10-35°C, and the reaction time is 2.5-8h. After the reaction is completed, add 50g of water to dissolve the salt and catalyst generated by the reaction, let go of the saline solution, and wash once with 50g of water. Collect the organic phase, heat and reflux to separate the water, cool down the organic phase after water separation by 10-15°C, crystallize, and filter to obtain 4-p-toluenesulfonamido-2,2,6,6-tetramethylpiperidine , the product yield is 90.85%, and the melting point is 179-180°C.

Embodiment 2

[0020] In a 250mL four-neck flask, add 60g of solvent, 15.6g of 4-amino-2,2,6,6-tetramethylpiperidine, 15.4g of catalyst, 26.7g of p-toluenesulfonyl chloride, and reflux and condense Tube, thermometer, start the agitator, control the temperature at 10-35°C, and the reaction time is 2.5-8h. After the reaction is completed, add 50g of water to dissolve the salt and catalyst generated by the reaction, let go of the saline solution, and wash once with 50g of water. Collect the organic phase, heat and reflux to separate the water, cool down the organic phase after water separation by 10-15°C, crystallize, and filter to obtain 4-p-toluenesulfonamido-2,2,6,6-tetramethylpiperidine , the product yield is 91.06%, and the melting point is 179-180°C.

Embodiment 3

[0022] In a 250mL four-neck flask, add 60g of solvent, 15.6g of 4-amino-2,2,6,6-tetramethylpiperidine, 16.5g of catalyst, 28.6g of p-toluenesulfonyl chloride, and reflux and condense Tube, thermometer, start the agitator, control the temperature at 10-35°C, and the reaction time is 2.5-8h. After the reaction is completed, add 50g of water to dissolve the salt and catalyst generated by the reaction, let go of the saline solution, and wash once with 50g of water. Collect the organic phase, heat and reflux to separate the water, cool down the organic phase after water separation by 10-15°C, crystallize, and filter to obtain 4-p-toluenesulfonamido-2,2,6,6-tetramethylpiperidine , the product yield is 91.96%, and the melting point is 179-180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com