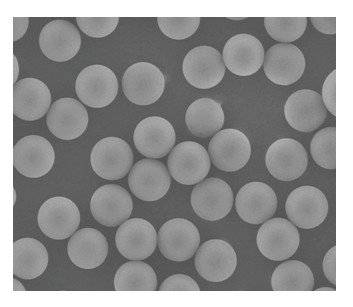

Application of monodispersed polymethacrylate ion exchange chromatography medium in column chromatography purification of fondaparinux sodium

A technology of polymethacrylate and ion-exchange chromatography, which is applied in organic chemistry, chemical instruments and methods, preparation of sugar derivatives, etc., can solve problems such as limited application and deformation, and achieve high purity, recovery, and high flow rate , the effect of high pressure flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

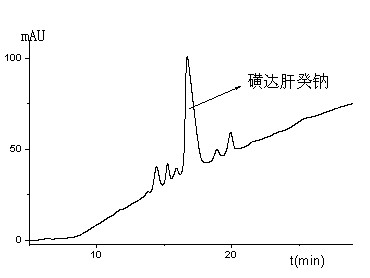

[0021] Purification of Fondaparinux Sodium:

[0022] A 26×310mm glass chromatographic column was used, and Uni Q-50S (produced by Suzhou Nan Microbe Technology Co., Ltd.) was used as the chromatographic packing material to fill the chromatographic column. The column volume was 164.5mL. The column was then equilibrated with 2.0 CV of ultrapure water at a flow rate of 10 mL / min. The crude product of fondaparinux sodium (purity 70%) was dissolved in ultrapure water, the concentration of the crude product was 4 mg / mL, and the sample volume was 250 mL. After sample loading, wash 2.0BV with ultrapure water first, then elute 3.5BV with 0.3M NaCl to remove impurities, then elute with 0.44M NaCl and collect the eluate in separate tubes, and finally elute with 1.0M NaCl until there is no UV absorption . After testing the collected liquid, the recovery rate of chromatographic purity above 99% is about 30%, and the recovery rate of chromatographic purity above 97% is about 60%.

Embodiment 2

[0024] Purification of Fondaparinux Sodium:

[0025] A 26×310mm glass chromatographic column was used, and Q Sepharose Fast Flow (GE Healthcare, particle size range 45-165 microns) was used to fill the chromatographic column with a column volume of 164.5mL. Activate the chromatographic column with NaCl, and then equilibrate the chromatographic column with 2.0CV ultrapure water at a flow rate of 10 mL / min. The crude product of fondaparinux sodium (purity 70%) was dissolved in ultrapure water, the concentration of the crude product was 4 mg / mL, and the sample volume was 250 mL. After loading the sample, wash 2.0BV with ultrapure water first, then elute 5BV with 0.36M NaCl to remove impurities, then elute with 0.6M NaCl and collect the eluate in separate tubes, and finally elute with 1.0M NaCl until there is no UV absorption. After testing the collected solution, the recovery rate of chromatographic purity above 99% is about 28%, and the recovery rate of chromatographic purity a...

Embodiment 3

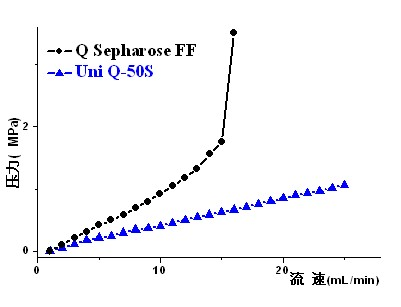

[0027] Filling pressure performance test:

[0028] A 10×220mm glass chromatographic column was used, and Uni Q-50S (Suzhou Nan Microbe Technology Co., Ltd.) was used as the chromatographic filler. After the column was packed, the chromatographic column was equilibrated with 3CV ultrapure water at a flow rate of 1mL / min and the back pressure of the chromatographic column was measured. Start at this flow rate, gradually increase the flow rate, measure the back pressure of the chromatographic column every time the flow rate increases by 1mL / min, and make a flow rate-pressure curve, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com