Protective solution for low pressure oil-well operations

A technology for protecting fluids and oil wells, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced production time and service life of operating wells, long flowback time of oil and water wells, and reduced well production, achieving Simple on-site implementation, low formation damage, and the effect of restoring production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

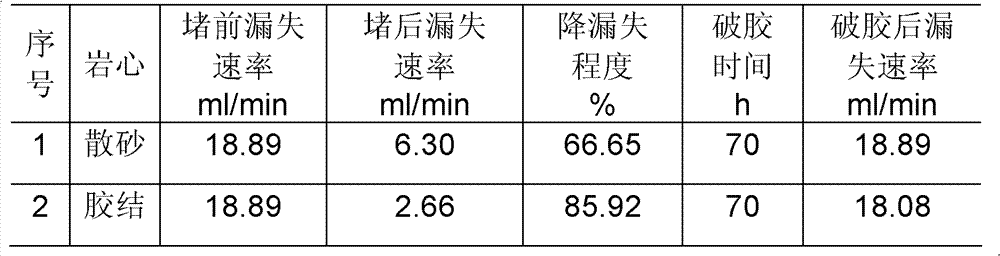

Examples

Embodiment 1

[0031] 1. Preparation of leakage reducing agent A:

[0032] The leakage reducing agent A is mixed according to the following proportions: high-molecular polyacrylamide with a molecular weight of 18 million, 50% by mass; low-molecular polyacrylamide with a molecular weight of 6 million, 30% by mass; acrylamide monomer, The mass percentage is 20%, put into the reaction kettle and stir for 10 minutes to make the leakage reducing agent A.

[0033] 2. Preparation of leakage reducing agent B:

[0034]1. Preparation of organic chromium intermediate YJG: Add 50% by mass of fructose and 30% of water into the reaction kettle, heat to 80°C with stirring, slowly pour 10% by mass of chromium hydroxide into the reaction vessel Kettle, open the reaction for 1h. Then slowly add potassium carbonate with a mass percentage of 10%, continue to react for 20 minutes, drop to room temperature and discharge and filter, pour the obtained filtrate into anhydrous ethanol solution and stir, and then th...

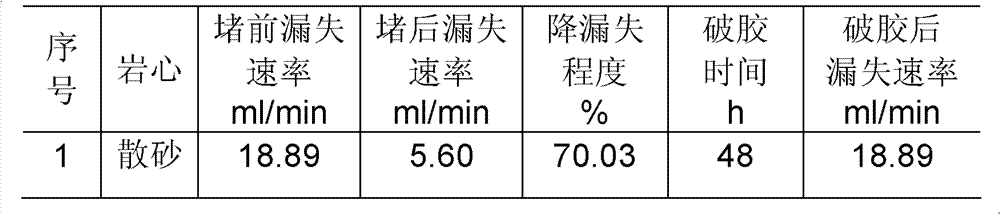

Embodiment 2

[0048] 1. Preparation of leakage reducing agent A:

[0049] The leakage reducing agent A is mixed according to the following proportions: high-molecular polyacrylamide with a molecular weight of 18 million, 60% by mass; low-molecular polyacrylamide with a molecular weight of 6 million, 20% by mass; acrylamide monomer, The mass percentage is 20%, and the preparation method is the same as in Example 1.

[0050] 2. Preparation of leakage reducing agent B:

[0051] 1. Preparation of organic chromium intermediate YJG: the mass percent of raw materials is 45% fructose, 35% water, 8% chromium hydroxide, and 12% potassium carbonate.

[0052] 2, prepare resin intermediate SZT, the mass percentage of raw material is 25% urea, 58% formaldehyde solution, and described formaldehyde solution concentration is 37%, 5 drops of 2mol / L sodium hydroxide, 5 drops of glacial acetic acid, 16.5 % furfuryl alcohol, 0.5% triethanolamine.

[0053] 3. Preparation of leakage reducing agent B: 40% organ...

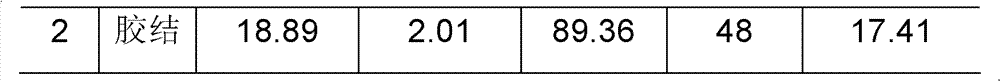

Embodiment 3

[0066] 1. Preparation of leakage reducing agent A:

[0067] The leakage reducing agent A is mixed according to the following proportions: high-molecular polyacrylamide with a molecular weight of 18 million, 55% by mass; low-molecular polyacrylamide with a molecular weight of 6 million, 30% by mass; acrylamide monomer, The mass percentage is 15%, and the preparation method is the same as in Example 1.

[0068] 2. Preparation of leakage reducing agent B:

[0069] 1. Preparation of organic chromium intermediate YJG: the mass percentage of raw materials is 55% fructose, 20% water, 12% chromium hydroxide, and 13% potassium carbonate.

[0070] 2, prepare resin intermediate SZT, the mass percentage of raw material is 28% urea, 60% formaldehyde solution, and described formaldehyde solution concentration is 37%, 5 drops of 2mol / L sodium hydroxide, 5 drops of glacial acetic acid, 11.6 % furfuryl alcohol, 0.4% triethanolamine.

[0071] 3. Preparation of leakage reducing agent B: 50% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com