A method for producing porcine transmissible gastroenteritis virus using a bioreactor

A bioreactor and infectious technology, applied in the field of using bioreactors to produce swine transmissible gastroenteritis virus, can solve the problems of high production cost, difficult production, high labor intensity, etc., to improve vaccine quality and output, reduce The effect of production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

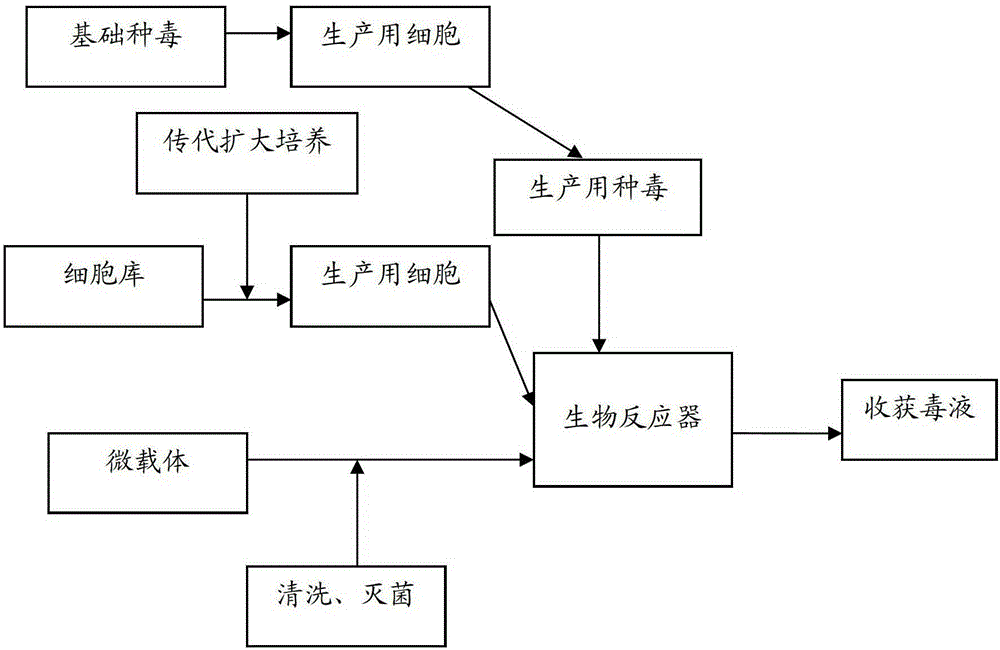

Method used

Image

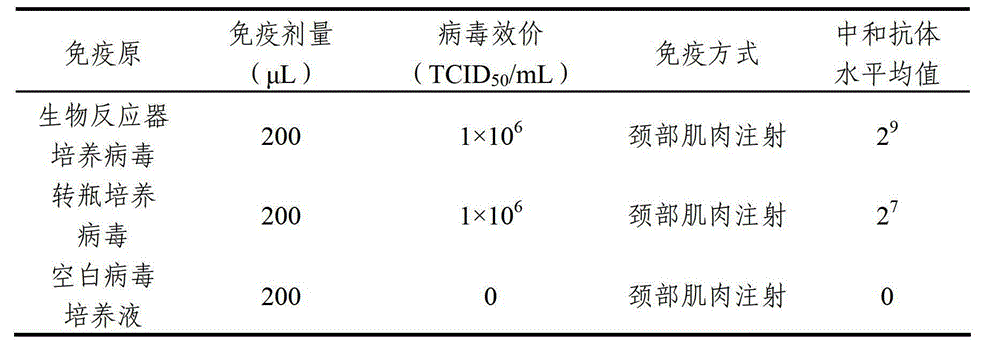

Examples

Embodiment 1

[0030] (1) Choose a bioreactor as the means of cultivation: 7L Swiss Lambda bioreactor.

[0031] (2) Select the microcarrier as the carrier for cell attachment and growth: microcarrier Cytodex2.

[0032] (3) Cleaning and sterilization methods of microcarriers: 1) Weigh 10 g / L of Cytodex2 microcarriers and soak in 2LPBS solution for 3 hours. 2) Wash 3 times with 2LPBS each time. 3) Add 2LPBS solution to soak the microcarriers, and steam sterilize at 121° C. for 30 minutes.

[0033] (4) Select ST cells as cells for making seedlings.

[0034] (5) Passaging and culturing of cells for seedling preparation: the above-mentioned cells were digested and passaged by EDTA-trypsin (Hank'S solution containing 0.25% trypsin and 0.02% EDTA), and then prepared with 95% MEM solution, 5% calf serum, 200IU / mL of penicillin sodium and streptomycin sulfate, the pH value of the cell growth medium was adjusted to 7.2, and the culture temperature was 37°C. When a good monolayer is formed, it is ...

Embodiment 2

[0040] (1) Choose a bioreactor as the means of cultivation: 7L Swiss Lambda bioreactor.

[0041] (2) Select the microcarrier as the carrier for cell attachment and growth: microcarrier Cytodex3.

[0042] (3) Cleaning and sterilization methods of microcarriers: 1) Weigh Cytodex3 microcarriers at 6 g / L and soak in 2 LPBS solution for 3 hours. 2) Wash 3 times with 2LPBS each time. 3) Add 2LPBS solution to soak the microcarriers, and steam sterilize at 121° C. for 30 minutes.

[0043] (4) Select vero cells as cells for seedling production.

[0044] (5) Passaging and culturing of cells for seedling preparation: the above-mentioned cells were digested and passaged by EDTA-trypsin (Hank'S solution containing 0.25% trypsin and 0.02% EDTA), and then prepared with 96% MEM solution, 4% calf serum, 200IU / mL of penicillin sodium and streptomycin sulfate, the pH value of the cell growth medium was adjusted to 7.2, and the culture temperature was 37°C. When a good monolayer is formed, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com