Silver nanoparticle film with mixed valent state, preparation method thereof and application thereof

A technology of silver nanoparticles and mixed valence state, which is applied in the fields of nanomaterials and electrical storage films, and can solve the problems of unfavorable silver nanoparticle film preparation, high annealing temperature, unfavorable mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

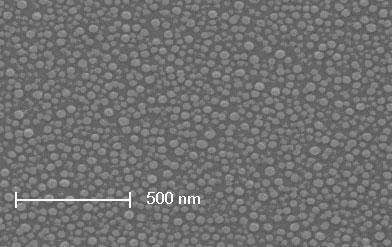

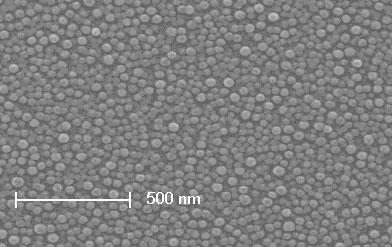

[0025] At a pressure of 2×10 -3 In a vacuum chamber of Pa, a silver film with a thickness of about 4.5 nm was deposited on a clean and flat mica surface by vacuum thermal evaporation. The thin film samples were then annealed at a temperature of about 150°C in the atmosphere. After cooling, they were observed with a scanning electron microscope (SEM). The SEM image of the sample annealed for 10 minutes is as figure 1 Shown; the SEM image of the sample annealed for 90 minutes is shown in figure 2 shown. Both images show that the particles are evenly distributed, most of the particles are between 20 and 40 nanometers in size, a few larger ones are about 50 nanometers, and a few smaller ones are about 10 nanometers.

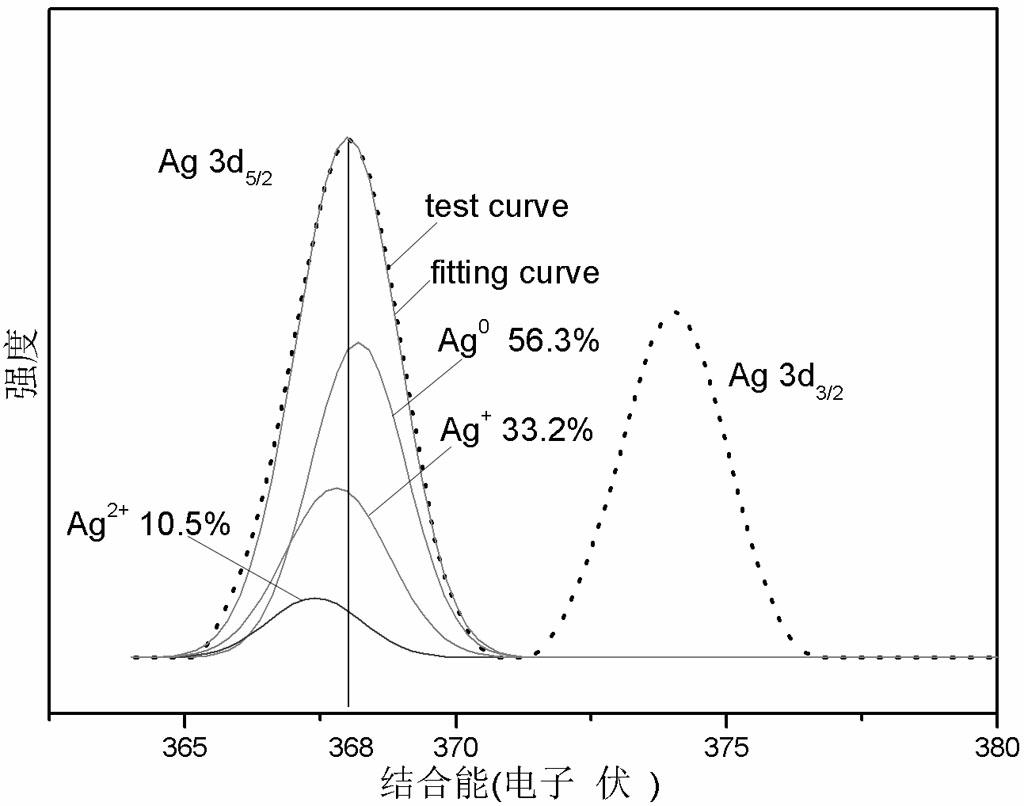

[0026] The samples annealed for 90 minutes were analyzed by XPS, such as image 3 shown. It shows that elemental silver accounts for 56.3%, monovalent silver accounts for 33.2%, and divalent silver accounts for 10.5% in the sample. This indicates that the s...

Embodiment 2

[0028] At a pressure of 2×10 -3 In a vacuum chamber of Pa, a silver film with a thickness of about 4.5 nanometers is deposited on a clean and flat silicon wafer surface by vacuum thermal evaporation. The thin film samples were then annealed at a temperature of about 150°C in the atmosphere. After cooling, they were observed with a scanning electron microscope (SEM). The SEM image of the sample annealed for 90 minutes is as Figure 4 shown. The image shows that the particles are evenly distributed, most of the particles are in the range of 20 to 40 nanometers, a few larger ones are about 50 nanometers, and a few smaller ones are about 10 nanometers.

Embodiment 3

[0030] At a pressure of 2×10 -3 In a vacuum chamber of Pa, a 200 nanometer thick aluminum film is deposited on a clean and flat glass slide by vacuum thermal evaporation method, and placed for later use. A silver film about 4.5 nm thick is then deposited on the surface of the aluminum film. The thin film samples were then annealed at a temperature of about 150°C in the atmosphere. After cooling, they were observed with a scanning electron microscope (SEM). The SEM image of the sample annealed for 90 minutes is as Figure 5 shown. The image shows that the particles are evenly distributed, most of the particles are in the range of 20 to 40 nanometers, a few larger ones are about 50 nanometers, and a few smaller ones are about 10 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com