Method and device for testing parameters of metal pipe fitting with electric eddy under the eccentric state of probe

A technology of metal pipe fittings and detection methods, which is applied in the direction of electromagnetic measuring devices, measuring devices, and electric devices, etc., can solve problems such as poor promotion, high price, and effect effects, and achieve accurate and fast online detection, accurate measurement parameters, and frequency Responsive wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

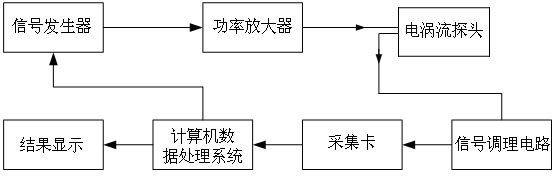

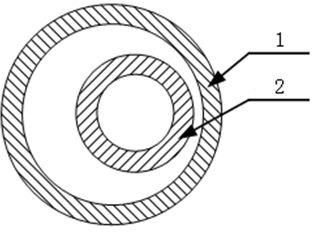

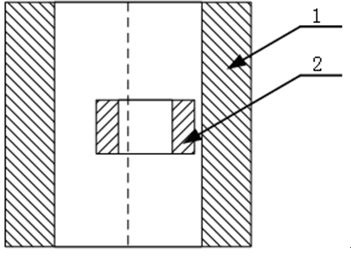

[0024] The eddy current detection method of metal pipe fitting parameters in the probe eccentric state of the present invention:

[0025] Such as figure 2 , image 3 As shown, because the inner diameter of the pipe fitting is larger than the outer diameter of the eddy current probe, it is difficult for the eddy current probe to align with the axis of the pipe fitting if the shaft alignment device is not used or the shaft alignment device is not accurate enough, that is, the eddy current probe is eccentric. The invention adopts the eccentricity compensation function for the eddy current probe, so that the influence of the eccentricity of the eddy current probe on the detection result can be suppressed, and the detection accuracy and reliability can be improved. Specific steps are as follows:

[0026] (1) Put the eddy current probe into the metal pipe to be tested so that the eddy current probe is parallel to the pipe, and the signal generator generates a sinusoidal signal un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com