Biological processing method for S-allyl-L-cysteine-rich (SAC-rich) garlic

A cysteine and bioprocessing technology, applied in food science, application, food preparation and other directions, can solve the problems of complicated steps and long garlic cycle, and achieve the effects of simple and easy method, short production cycle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

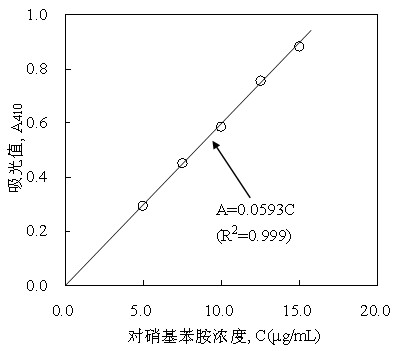

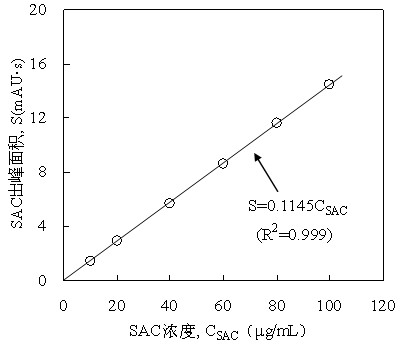

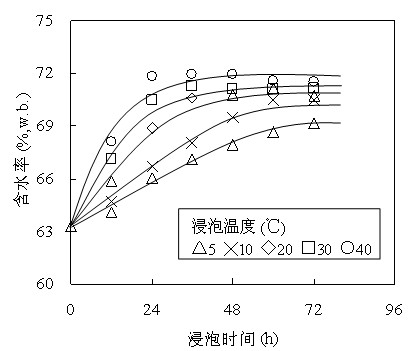

[0033] Place the washed garlic heads in 5°C, 25mmol / L CaCl 2 Soak in the solution for 3 days, the pH is 8. During the soaking process, the soaking liquid should be replenished in time to ensure that the garlic is submerged, so as to ensure the moisture required for the garlic to absorb water. During the soaking process, samples were taken regularly at 24h, 48h, and 72h to determine the water content, SAC content, and γ-GTP activity. The soaked garlic is ground and mixed with CaCl 2 The solution forms a homogeneous reaction system. Adjust the pH to 8, and then place it in a shaker at 37° C. at 50 rpm to carry out the enzyme reaction. The resulting product is prepared into garlic paste. During the enzyme reaction process, 20 mL of samples were regularly sampled according to 4h, 8h, and 12h, centrifuged at 8000rpm and room temperature for 40min, the supernatant was taken out and the volume was adjusted to 50mL with distilled water to obtain the SAC extract. Take 1mL of the S...

Embodiment 2

[0054] Place the washed garlic heads in 10°C, 25mmol / L CaCl 2 Soak in the solution for 3 days, the pH is 8. During the soaking process, the soaking liquid should be replenished in time to ensure that the garlic is submerged, so as to ensure the moisture required for the garlic to absorb water. During the soaking process, samples were taken regularly at 24h, 48h, and 72h to determine the water content, SAC content, and γ-GTP activity. The soaked garlic is ground and mixed with CaCl 2 The solution forms a homogeneous reaction system. Adjust the pH to 8, and then place it in a shaker at 37° C. at 50 rpm to carry out the enzyme reaction. The resulting product is prepared into garlic paste. During the enzyme reaction process, 20 mL of samples were regularly sampled according to 4h, 8h, and 12h, centrifuged at 8000rpm and room temperature for 40min, the supernatant was taken out and the volume was adjusted to 50mL with distilled water to obtain the SAC extract. Take 1mL of the ...

Embodiment 3

[0057] Place the cleaned garlic heads at 20°C without MgCl 2 Soak in deionized water with a pH of 6 for 3 days. During the soaking process, the soaking liquid should be replenished in time to ensure that the garlic is submerged, so as to ensure the moisture required for the garlic to absorb water. During the soaking process, samples were taken regularly at 24h, 48h, and 72h to determine the water content, SAC content, and γ-GTP activity. The soaked garlic is ground and mixed with CaCl 2 The solution forms a homogeneous reaction system. Adjust the pH to 8, and then place it in a shaker at 37° C. at 100 rpm to carry out the enzyme reaction. The resulting product is prepared as garlic powder. During the enzyme reaction process, 20 mL of samples were regularly sampled according to 4h, 8h, and 12h, centrifuged at 8000rpm and room temperature for 40min, the supernatant was taken out and the volume was adjusted to 50mL with distilled water to obtain the SAC extract. Take 1mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com