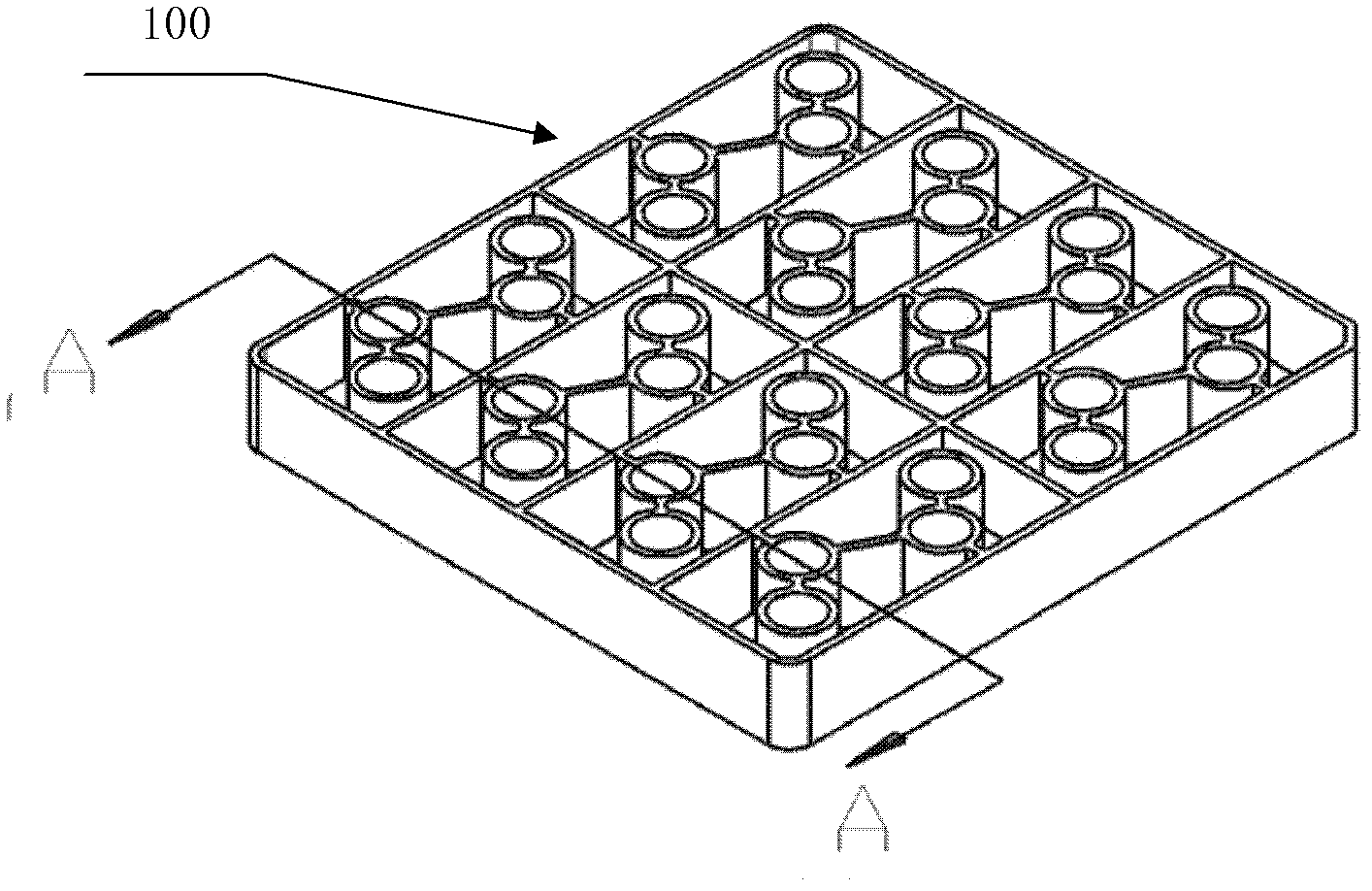

Microfluidic chip with diversion body and application thereof

A technology of microfluidic chip and conducting fluid, applied in fluid controllers, laboratory containers, instruments, etc., can solve problems such as affecting test results, affecting reactions, errors, etc., to improve reaction efficiency, reduce contact time, control The effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of coated diversion spheres

[0047] 1) Dilute the carcinoembryonic antibody used for coating 1:6000 times with 50mM sodium carbonate-sodium bicarbonate buffer solution of pH9.6, and set aside;

[0048] 2) Place a certain amount of diversion spheres in a beaker, and add the above-mentioned diluted carcinoembryonic antibody solution according to the calculation according to the amount of 100 μl per sphere;

[0049] 3) The above-mentioned beaker is sealed, placed in a 4°C environment, and coated for 20 hours;

[0050] 4) After the coating is completed, wash twice with the washing solution, calculated as 300 μl / coated sphere, and the washing solution composition is 10 mM PBS with pH 7.4 containing 5% Tween-20;

[0051] 5) After washing, place the coated ball on water-absorbing filter paper to absorb the remaining solution, then place it in a beaker, add a certain amount of blocking solution according to the amount of 150ui / coated ball, and seal at r...

Embodiment 2

[0053] Example 2: Irregular diversion body

[0054] The diversion body placed in the waste liquid pool is made of silica gel, and its shape is the same as that of the waste liquid pool, and the surface is not coated.

Embodiment 3

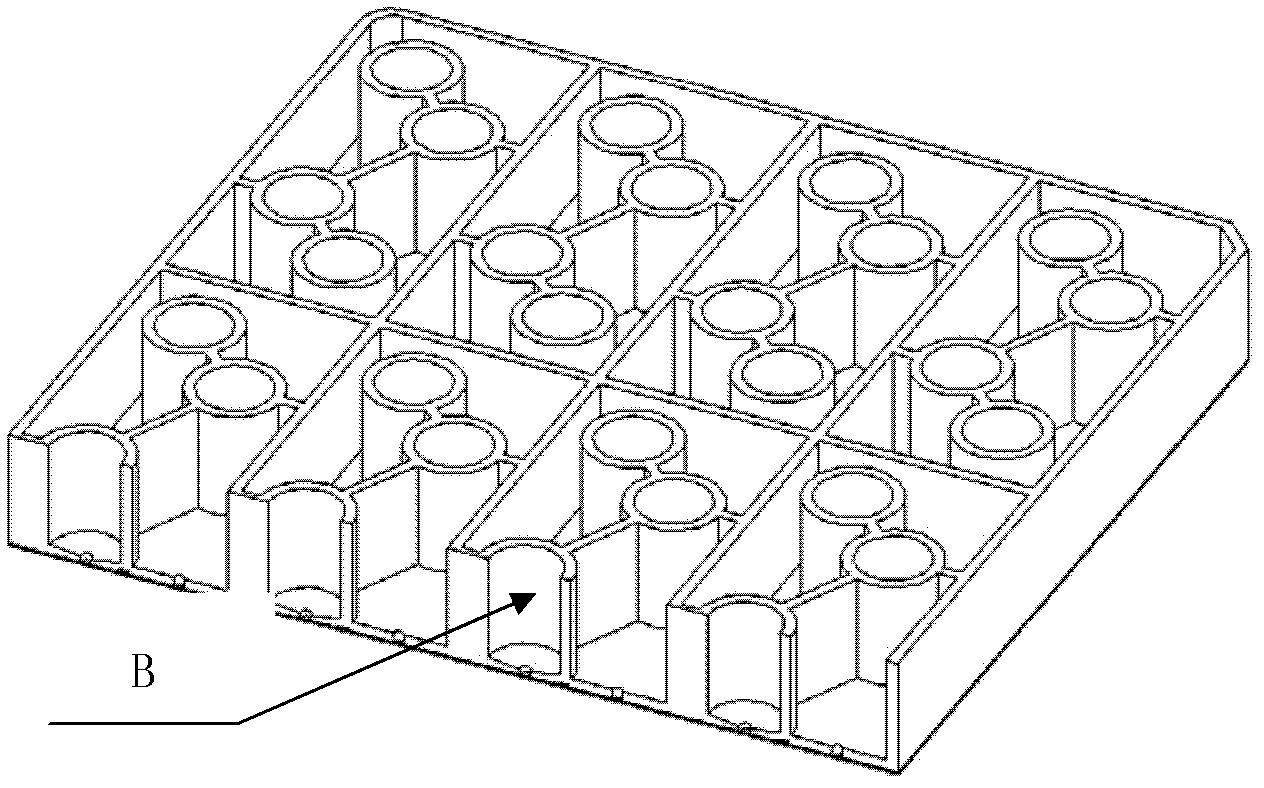

[0055] Example 3: Polymer microfluidic chip with flow-guiding spheres

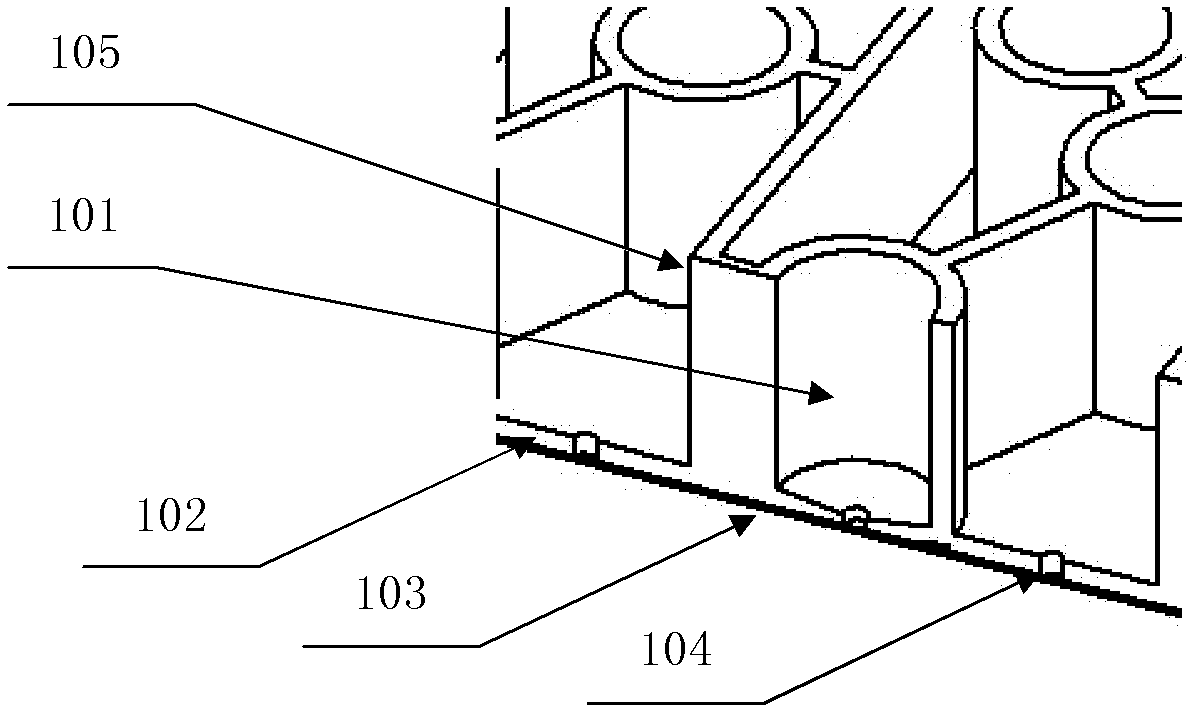

[0056] 6 solution pools, see Figure 7 : a sample pool 201, a diluent pool 202, a marker pool 203, a dissociation pool 204, a cleaning pool 205, a waste pool 206, a pool wall 105 of the solution pool, and a through hole 104 at the bottom of the pool;

[0057] 7 valves, see Figure 8 : sample pool valve 211, diluent pool valve 212, marker pool valve 213, dissociation pool valve 214, cleaning fluid valve 215, waste liquid valve 216, main valve 217, and channels 106 between the main valve and each branch valve ;

[0058] see Figure 9 , wherein, the sample pool valve 211+main valve 217+diluent pool valve 212 and the through hole 104 and the channel 106 form a bidirectional pump between the sample pool 201-the diluent pool 202, and the sample dilution pump 302;

[0059] see Figure 10 , wherein, the sample pool valve 211+main valve 217+cleaning liquid valve 21 5 and through holes, passages constitute a on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com