Processing system of blanking cutting off automatically for stamping parts

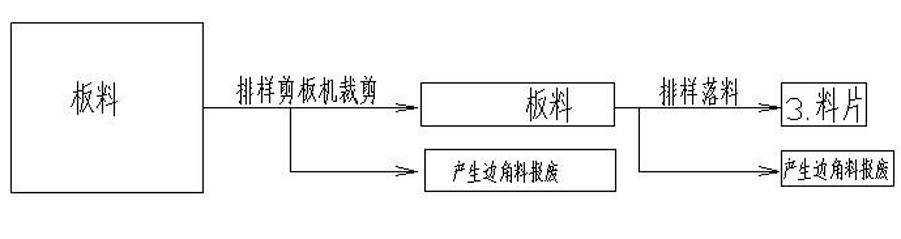

A processing system and technology for stamping parts, which are applied to blanking processing devices and automatic blanking fields for stamping parts, can solve the problems of increased labor intensity and production cost, high defective rate of manual blanking, and low production capacity of shears. Achieve the effect of reducing the labor intensity of workers and operators, improving the utilization rate of materials, and reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

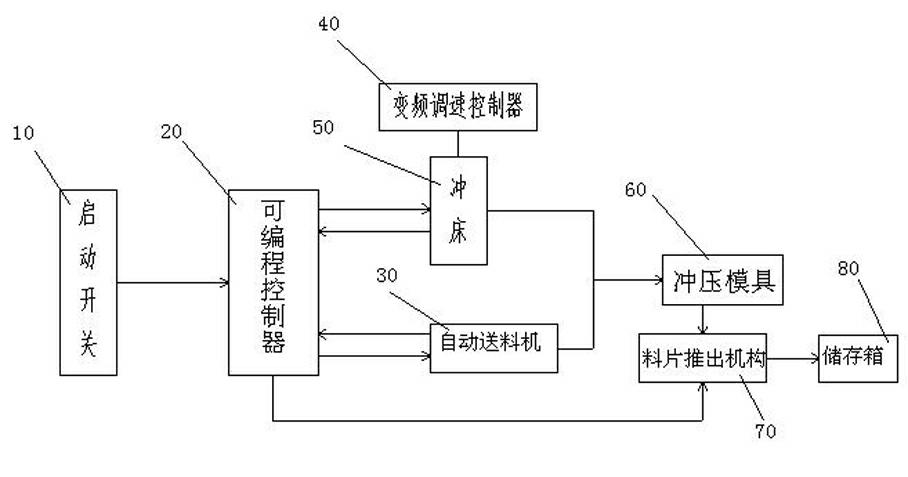

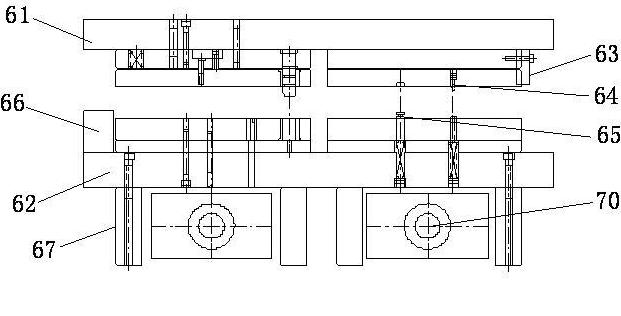

[0022] see figure 2 Referring to Fig. 4, an automatic cutting and blanking processing system for stamping parts according to the present invention includes an automatic feeder 30, a punch 50, a stamping die 60 installed on the punch 50, and a control system for controlling the operation of the automatic feeder 30 and the punch 50. The programming controller 20 and the frequency conversion speed regulation controller 40 for adjusting the punching speed of the punch press 50 . The frequency conversion speed controller 40 is connected with the punch press 50 through a circuit to control its stamping frequency; on the stamping die 60, a blank pushing mechanism 70 for pushing the blank after stripping out of the stamping mold 60 is installed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com