Laser welding method of foamed aluminum green packaging material and application thereof

A technology of laser welding and packaging materials, applied in laser welding equipment, welding media, welding equipment, etc., can solve the problems of porous structures that cannot support their own weight and collapse, and achieve the effects of changing performance, increasing structural density, and increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

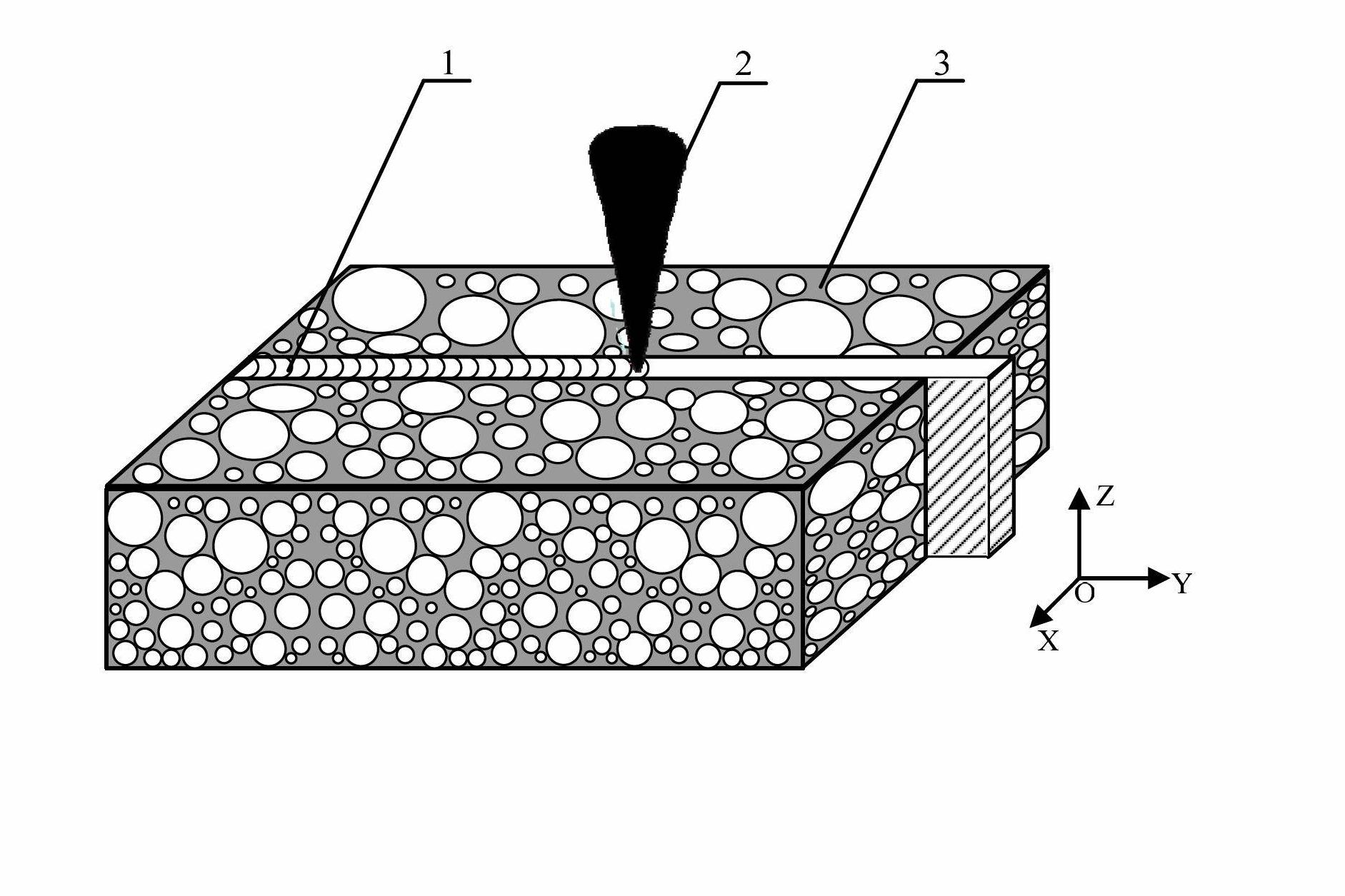

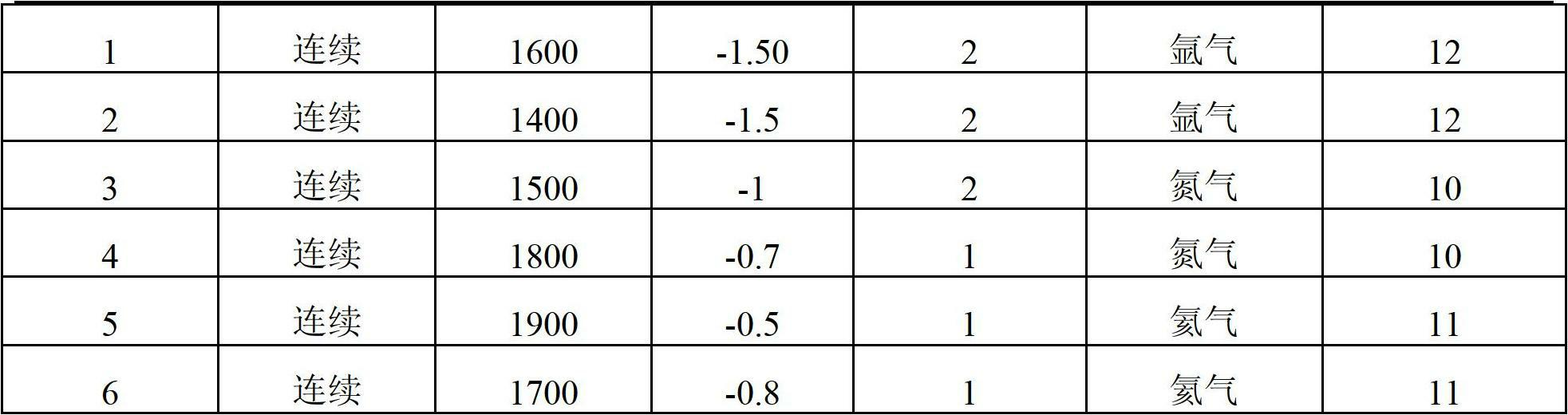

[0014] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0015] Adopt solid continuous Nd:YAG laser, its model is JK2003SM. The technical parameters of the laser equipment are shown in Table 1.

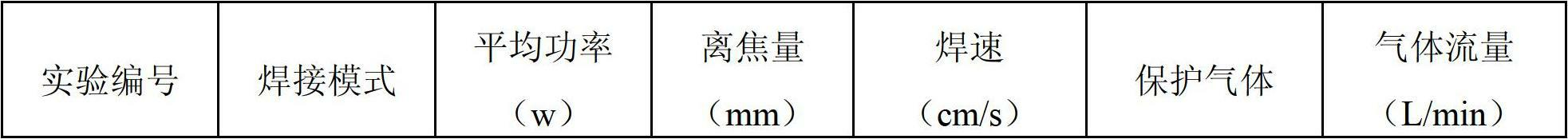

[0016] Table 1 Main technical parameters of JK2003SM laser

[0017] Average power of maximum output (W)

2000

Output pulse modulation peak power (W)

4000

600

Pulse frequency Modulation frequency(Hz)

100-1000 adjustable

Spot adjustable diameter range (mm)

0.3-0.9 continuously adjustable

[0018] In order to achieve the relative movement between the laser beam and the filled aluminum alloy, so as to achieve the purpose of welding, the special welding machine used is a multi-axis CNC laser processing machine, and its model is: TDJG-1.

[0019] The aluminum foam used is made of ZL111 aluminum alloy as the base material and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com