Method for producing granular monoammonium phosphate

A monoammonium phosphate and granular technology, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problem of not finding the method data of granular monoammonium phosphate, and achieve the goal of increasing product diversity, improving economic benefits, and improving adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

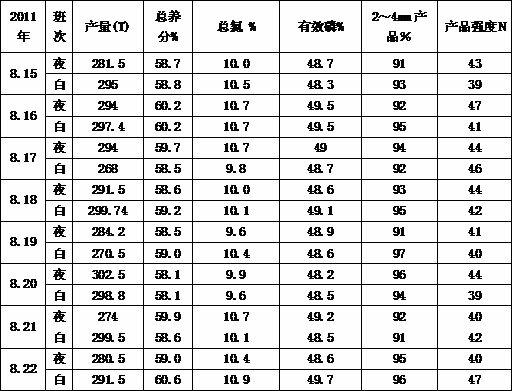

[0014] Wengfu (Group) Co., Ltd. Wengfu Phosphate Fertilizer Factory uses the method of the present invention to use the mother liquor and filter residue produced in the process of wet-purifying phosphoric acid raffinate to produce crystalline ammonium phosphate for 2×120,000 tons / powder MAP device to produce powdery phosphoric acid Monoammonium product, works well.

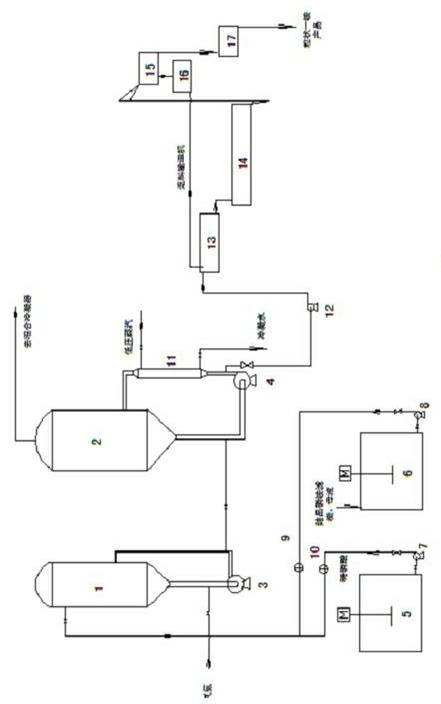

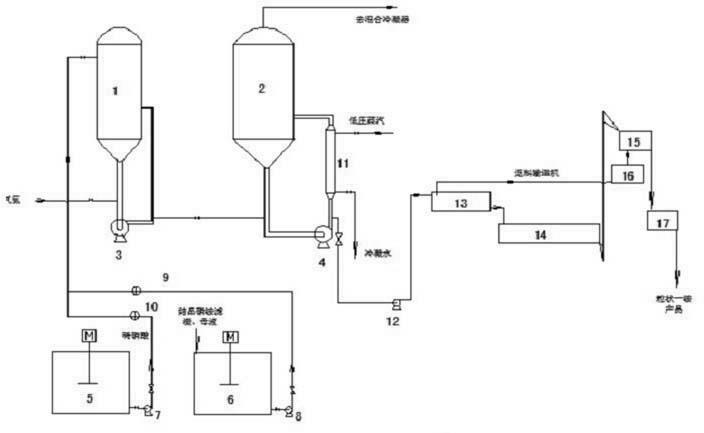

[0015] The equipment for producing granular monoammonium phosphate consists of ammoniation reactor 1, concentrated flash chamber 2, reaction circulation pump 3, ammonium phosphate slurry circulation pump 4, dilute phosphoric acid storage tank 5, crystalline ammonium phosphate filter residue, mother liquor storage tank 6 , phosphoric acid reaction circulation pump 3, delivery pump 7, crystalline ammonium phosphate mother liquor, filter residue delivery pump 8, crystalline ammonium phosphate mother liquor, filter residue metering equipment 9, phosphoric acid metering equipment 10, heater 11, ammonium phosphate slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com