Method for preparing two-dimensional Fe3O4 nano material

A two-dimensional nanomaterial and a technology for nanomaterials, which are applied in the field of preparing two-dimensional Fe3O4 nanomaterials, can solve the problems of large proportion of nanoparticles and are not very common, and achieve high reproducibility, uniform size distribution, and simple and novel synthesis methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Prepare egg white solvent: Take 2.5 mL of egg white separated from eggs in a beaker at room temperature, and add 10 mL of water while stirring. Let the egg whites dissolve in water for 1 h, then use a centrifuge to separate the undissolved white matter. Take the remaining solution as egg white solvent.

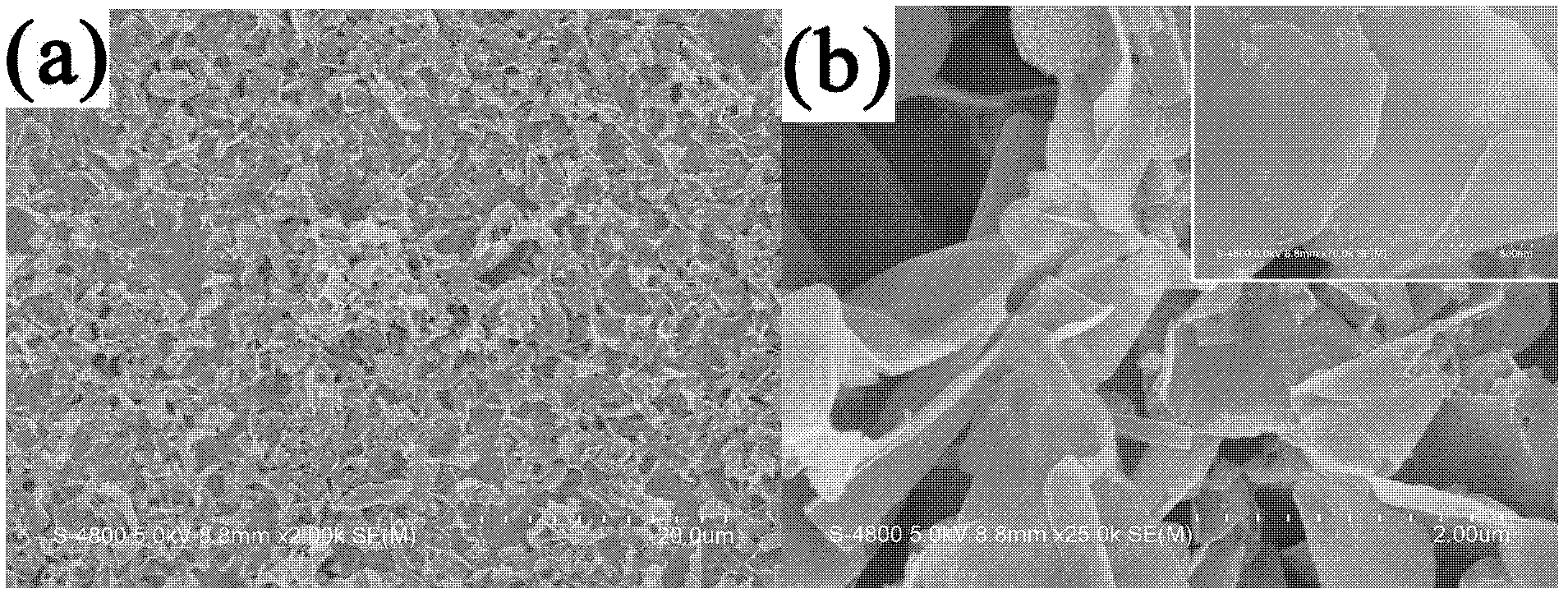

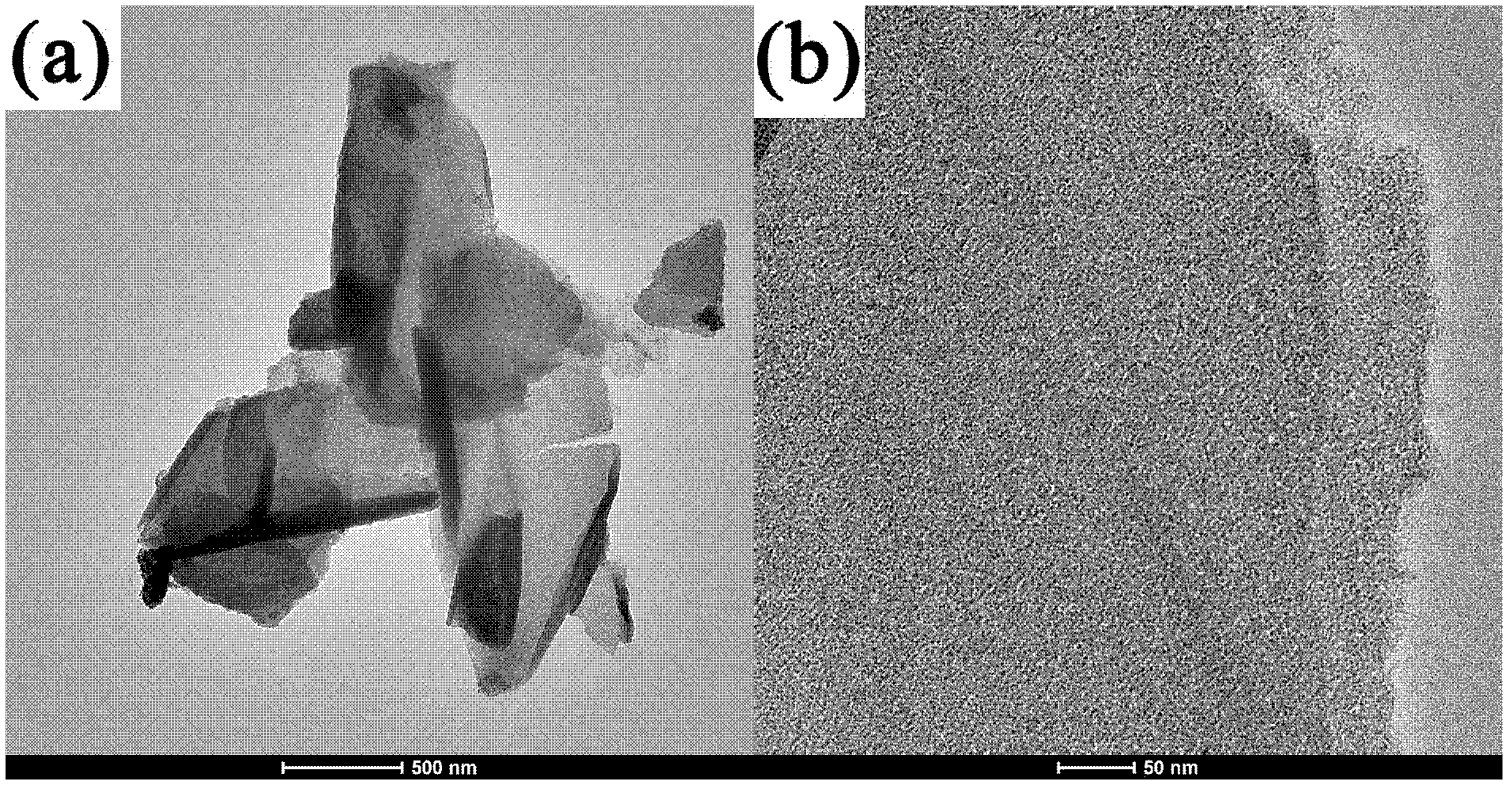

[0027] B. Preparation of two-dimensional Fe 3 o 4 Nanomaterials: Weigh 0.025g of ferric sulfate and add it to 12.5mL of egg white solvent, stir evenly to obtain an orange-yellow solution.

[0028] Dissolve 0.1 g of CTAB in 5 mL of absolute ethanol.

[0029] Slowly pour the orange-yellow solution into ethanol dissolved in CTAB, and stir for 15 minutes to obtain a yellow-white precipitated solution, then slowly add 5 mL of 50% hydrazine hydrate. After stirring for 15 minutes, the above-mentioned prepared reaction solution was transferred to a 30 mL polytetrafluoroethylene-lined stainless steel reaction kettle, and sealed. React in an oven at 120°C for 12 hours.

...

Embodiment 2

[0032] A. Prepare egg white solvent:

[0033] At room temperature, take 3 mL of the egg white separated from the egg in a beaker, and add 10 mL of water while stirring. Let the egg white dissolve in water for 12 hours, and then use a centrifuge to separate the undissolved white matter. Take the remaining solution as the reaction solvent.

[0034] B. Preparation of two-dimensional Fe 3 o 4 nanomaterials:

[0035] Weigh 0.015g of ferric sulfate and add it into the above-mentioned egg white solution, stir evenly to obtain an orange-yellow solution.

[0036] Take 0.08g CTAB and dissolve in 5mL of absolute ethanol.

[0037] Slowly pour the orange-yellow solution into ethanol dissolved in CTAB, and stir for 15 minutes to obtain a yellow-white precipitated solution, then slowly add 5 mL of 80% hydrazine hydrate. After stirring for 15 minutes, the above-mentioned prepared reaction solution was transferred to a 30 mL polytetrafluoroethylene-lined stainless steel reaction kettle, ...

Embodiment 3

[0040] A. Prepare egg white solvent:

[0041] At room temperature, take 3 mL of the egg white separated from the egg in a beaker, and add 10 mL of water while stirring. Let the egg whites dissolve in water for 1 h, then use a centrifuge to separate the undissolved white matter. Take the remaining solution as the reaction solvent.

[0042] B. Preparation of two-dimensional Fe 3 o 4 nanomaterials:

[0043] Weigh 0.015g of ferric sulfate and add it into the above-mentioned egg white solution, stir evenly to obtain an orange-yellow solution.

[0044] Dissolve 0.16 g of CTAB in 5 mL of absolute ethanol.

[0045] Slowly pour the orange-yellow solution into ethanol dissolved in CTAB, and stir for 15 minutes to obtain a yellow-white precipitated solution, then slowly add 5 mL of urea solution (0.04 g of urea dissolved in 5 mL of water). After stirring for 15 minutes, the above-mentioned prepared reaction solution was transferred to a 30 mL polytetrafluoroethylene-lined stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com