2,7-bis-anthracene naphthalene compound, light emitting layer material, organic electroluminescent element, display device and lighting device

A naphthalene compound and luminescent layer technology, which is applied in luminescent materials, electrical components, organic chemistry, etc., can solve problems such as life characteristics of organic EL components with high luminous efficiency, and achieve the effects of long component life and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

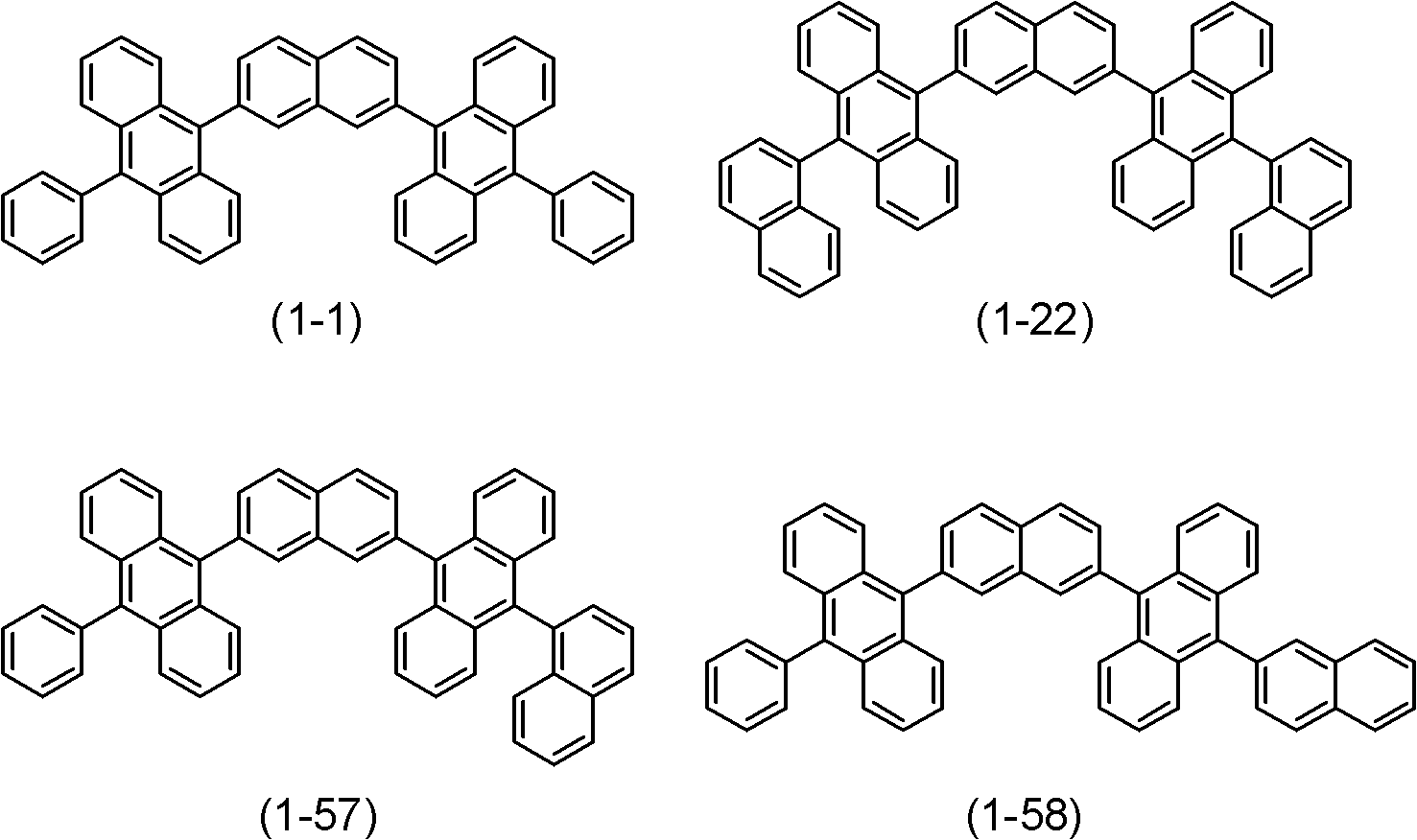

[0238] First, a synthesis example of the 2,7-bis-anthracenylnaphthalene compound used in the examples will be described below.

[0239]

[0240]

[0241]

[0242] First, under a nitrogen atmosphere, 48.1 g of naphthalene-2,7-diol and 380 ml of pyridine were put into a flask, and after cooling to 0° C., 203.1 g of trifluoromethanesulfonic anhydride was slowly added dropwise. Thereafter, the reaction solution was stirred at 0° C. for 1 hour, and then at room temperature for 2 hours. Next, water was added to the reaction solution, the target component was extracted with toluene, and the crude product obtained by concentrating the organic layer under reduced pressure was subjected to column purification using silica gel (solvent: heptane / toluene=6 / 1 (volume ratio)), Thus, 112.4 g (yield: 88%) of bis(trifluoromethanesulfonate)naphthalene-2,7-diyl ester was obtained as the first intermediate compound. The flow is shown in the following "Reaction 1".

[0243] Response 1

[...

example 1

[0308]

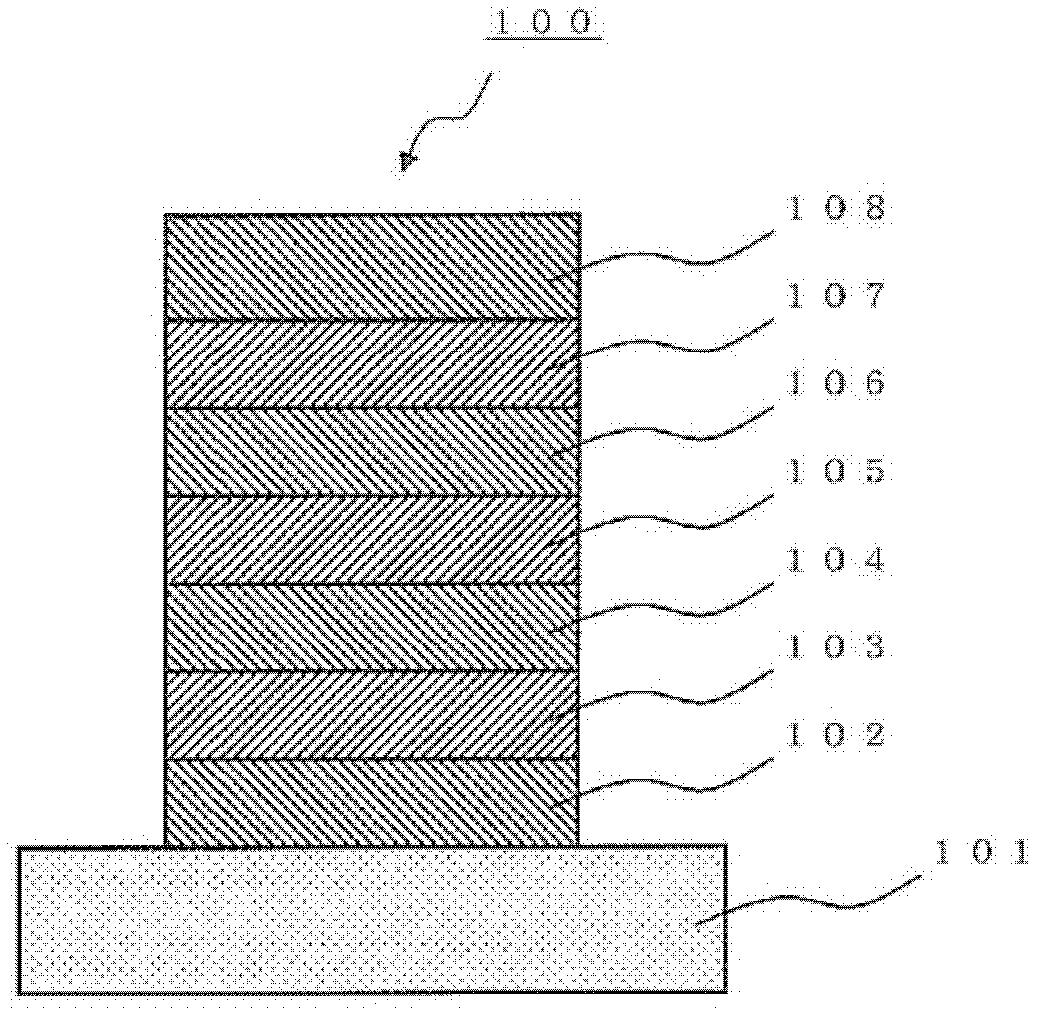

[0309] A glass substrate (manufactured by Optoscience Co., Ltd.) of 26 mm×28 mm×0.7 mm obtained by polishing ITO having a thickness of 180 nm by sputtering to 150 nm was used as a transparent support substrate. This transparent support substrate was fixed on the substrate holder of a commercially available vapor deposition apparatus (manufactured by Showa Vacuum Co., Ltd.), and then a molybdenum vapor deposition boat containing HI and a molybdenum vapor deposition boat containing NPD were attached. Boat, molybdenum vapor deposition boat containing compound (1-22) of the present invention, molybdenum vapor deposition boat containing BD1, molybdenum vapor deposition boat containing ET1, fluorine Lithium Fe (LiF) molybdenum vapor deposition boats and aluminum added tungsten vapor deposition boats.

[0310] The following layers were sequentially formed on the ITO film of the transparent support substrate. Depressurize the vacuum tank to 5×10 -4 Up to Pa, first, a hole...

example 2

[0326]

[0327] A glass substrate (manufactured by Optoscience Co., Ltd.) of 26 mm×28 mm×0.7 mm obtained by polishing ITO having a thickness of 180 nm by sputtering to 150 nm was used as a transparent supporting substrate. This transparent support substrate was fixed on the substrate holder of a commercially available vapor deposition apparatus (manufactured by Showa Vacuum Co., Ltd.), and then a boat for vapor deposition made of molybdenum containing HI and a boat for vapor deposition of molybdenum containing HT were attached. A boat, a molybdenum vapor deposition boat containing the compound (1-22) of the present invention, a molybdenum vapor deposition boat containing BD2, a molybdenum vapor deposition boat containing ET2, and a molybdenum vapor deposition boat containing 8 - A boat for vapor deposition made of molybdenum of lithium quinolate (Liq), a boat made of molybdenum added with magnesium, and a boat made of molybdenum added with silver.

[0328] The following laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com