Electrochromatic material made of isocyanate-triphenylamine and method for preparing electrochromatic material

An electrochromic material and ester-based triphenylamine technology, applied in the field of electrochromic materials and their preparation, can solve the problems of easy shedding, poor solvent corrosion resistance, etc., and achieve high cycle life, good chemical stability, and good electrical properties. Effects of chemical redox reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

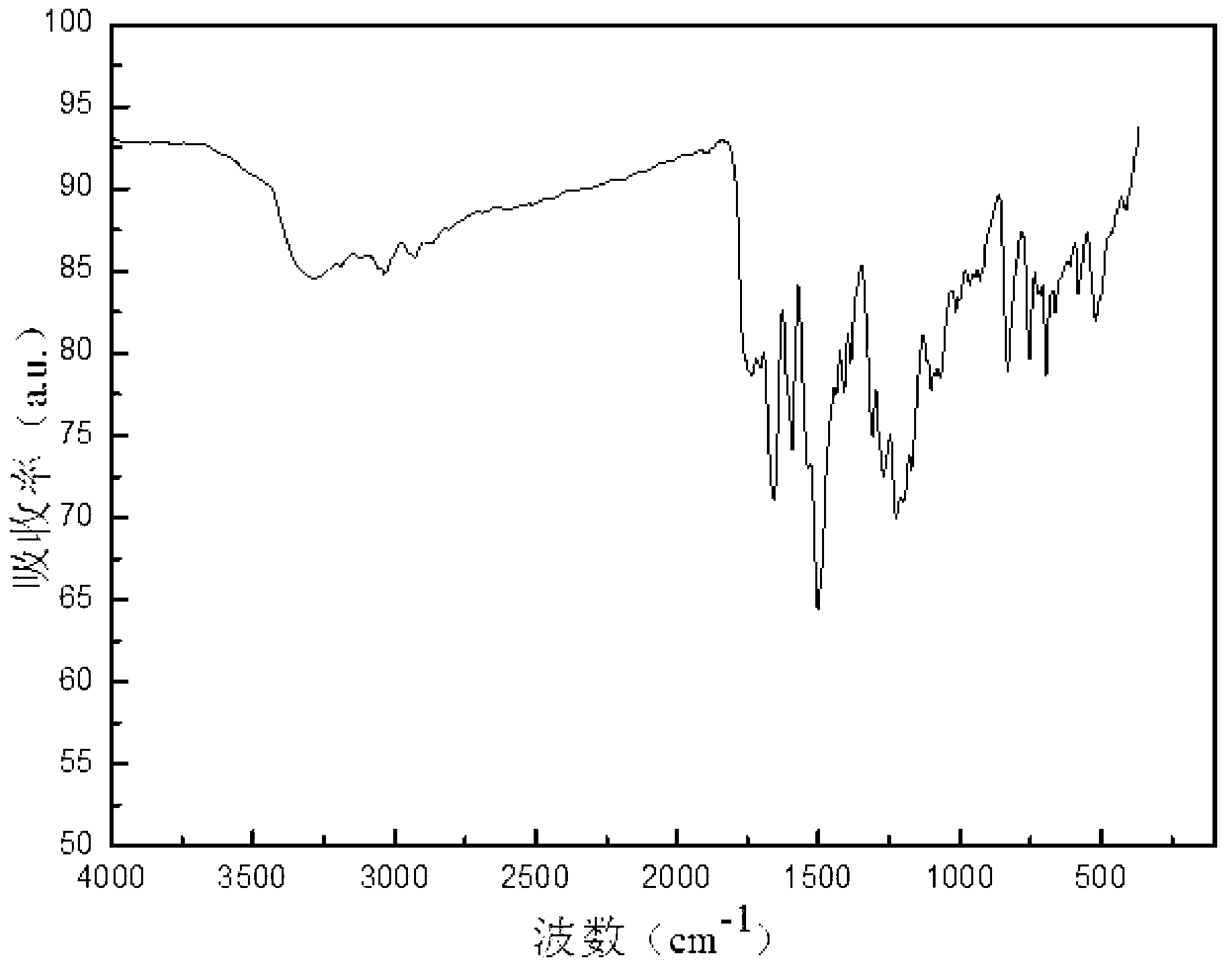

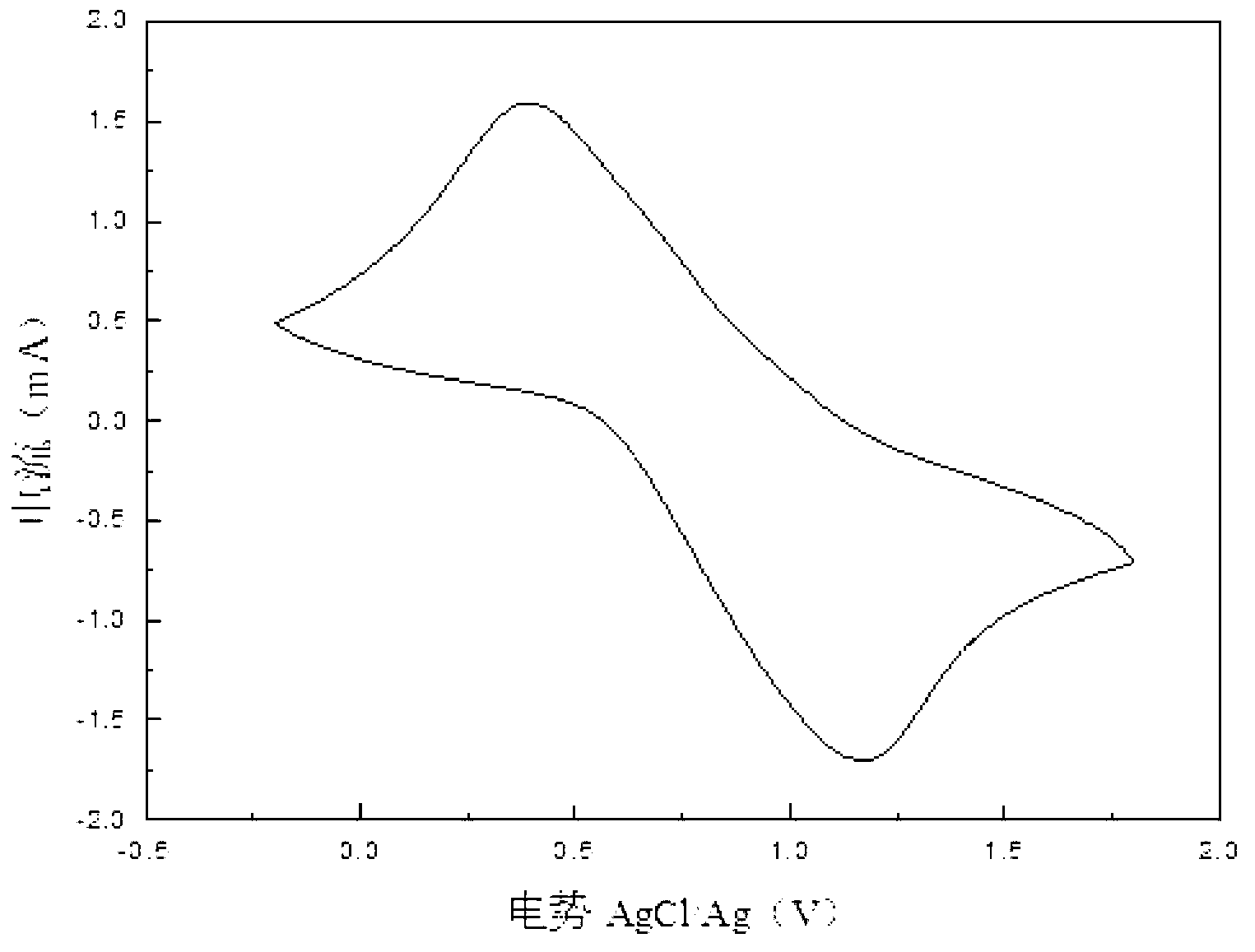

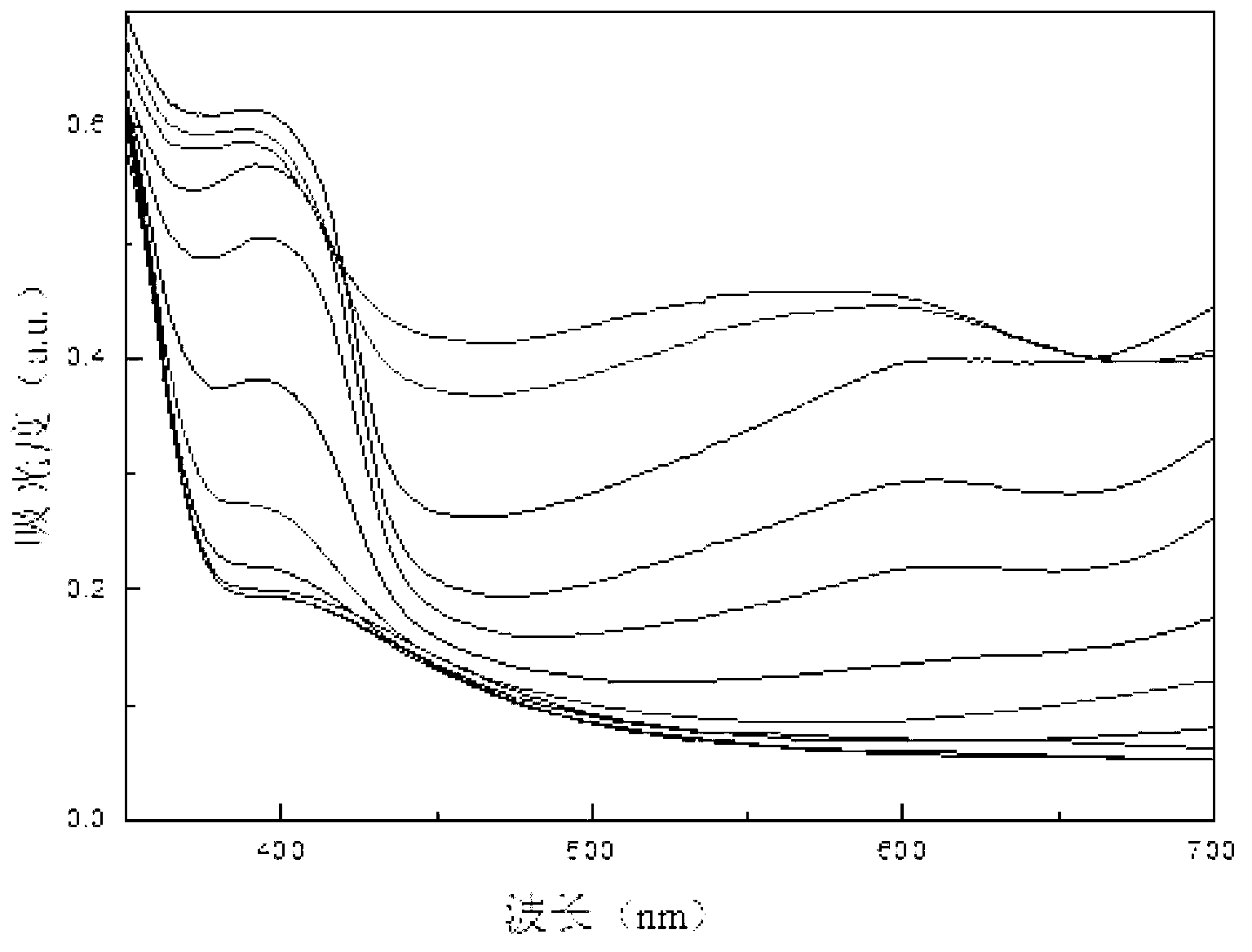

[0017] Specific Embodiment One: This embodiment is a method of electrochromic material prepared from isocyanate-based triphenylamine as a raw material, specifically as follows:

[0018] Add diisocyanate-based triphenylamine into anhydrous dichloroethane at room temperature, and then completely dissolve diisocyanate-based triphenylamine in anhydrous dichloroethane under the protection of nitrogen at a stirring speed of 50r / s-150r / s , and mix evenly to obtain a mixture, raise the temperature of the mixture from room temperature to 60°C-80°C, then add a dihydroxy monomer, and condense and reflux at a temperature of 60°C-80°C for 36h-60h, then cool to room temperature, and then adopt the method of filtration and separation to obtain a solid reaction product, and finally dry the obtained solid reaction product at a temperature of 40° C. to 50° C. to a constant weight to obtain an electrochromic material.

[0019] The mass ratio of the diisocyanate triphenylamine described in the pr...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dihydroxy monomer is phenolphthalein, bisphenol A, dihydroxybenzophenone or dihydroxybiphenyl. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: This embodiment is a method for preparing an electrochromic material with isocyanate-based triphenylamine as a raw material, specifically as follows:

[0031] Add triisocyanatotriphenylamine into anhydrous dichloroethane at room temperature, and then completely dissolve triisocyanatotriphenylamine in anhydrous dichloroethane under the protection of nitrogen with a stirring speed of 50r / s~150r / s , and mix evenly to obtain a mixture, raise the temperature of the mixture from room temperature to 60°C-80°C, then add a dihydroxy monomer, and condense and reflux at a temperature of 60°C-80°C for 36h-60h, then cool to room temperature, and then adopt the method of filtration and separation to obtain a solid reaction product, and finally dry the obtained solid reaction product at a temperature of 40°C to 50°C to a constant weight to obtain an electrochromic material.

[0032] The mass ratio of the triisocyanate triphenylamine described in the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com