Preparation method of CdZnSeS quantum dots

A technology of quantum dots and compounds, which is applied in the field of CdZnSeS quantum dots, can solve the problems of inability to synthesize quantum dots with different fluorescence, limited adjustment ability, uncertain subjective and objective factors, etc., so as to reduce the requirements of production equipment and reaction process Continuous, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

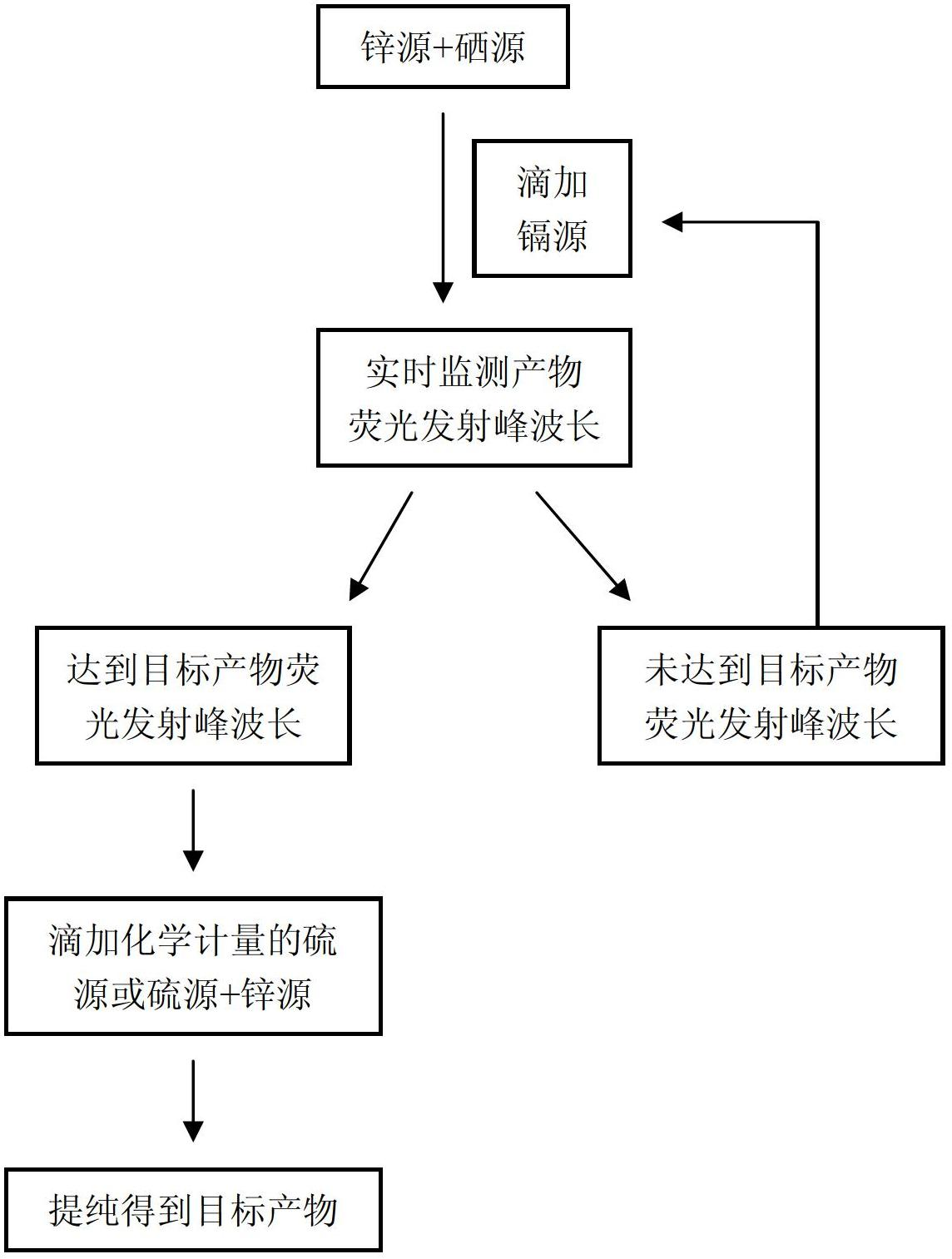

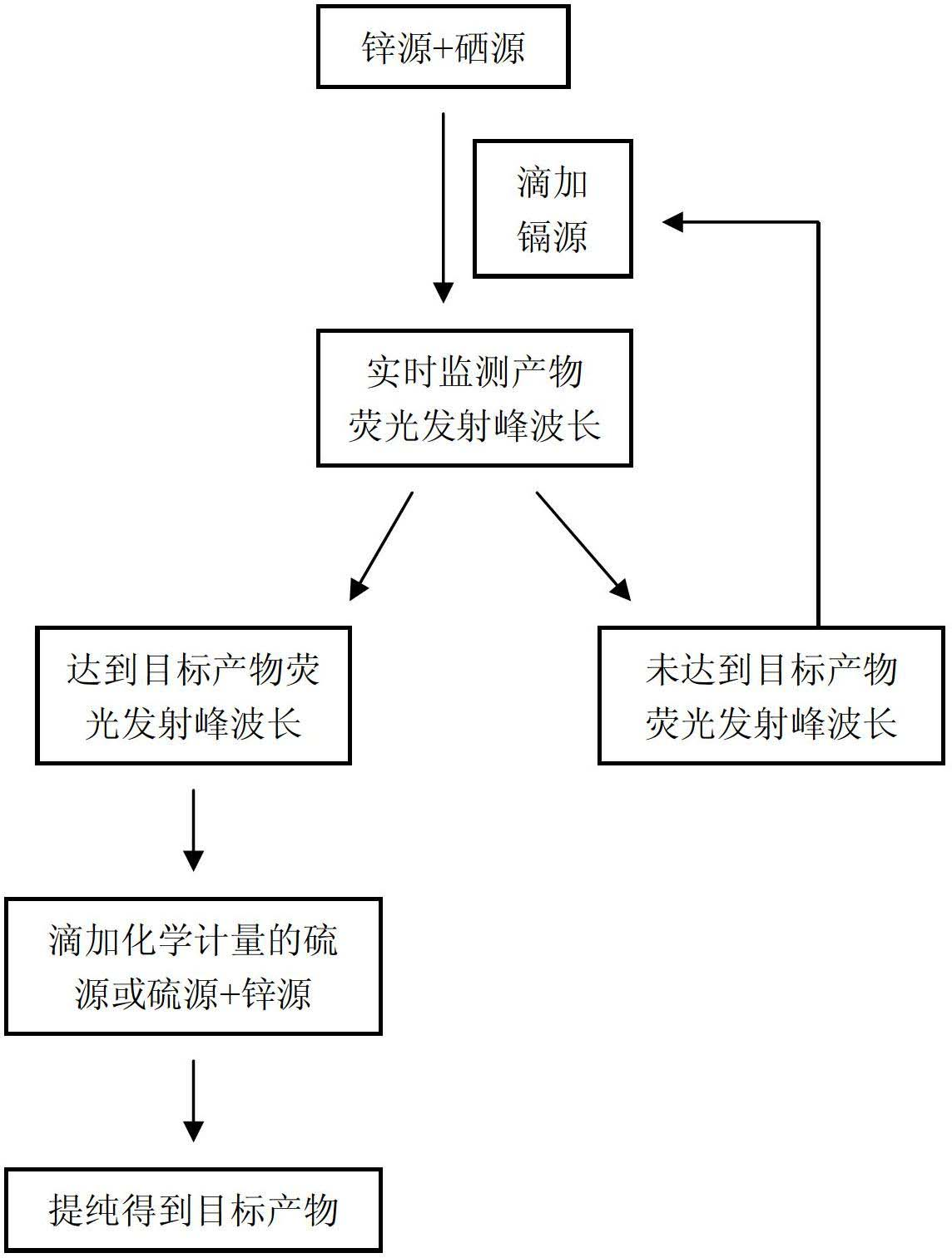

Method used

Image

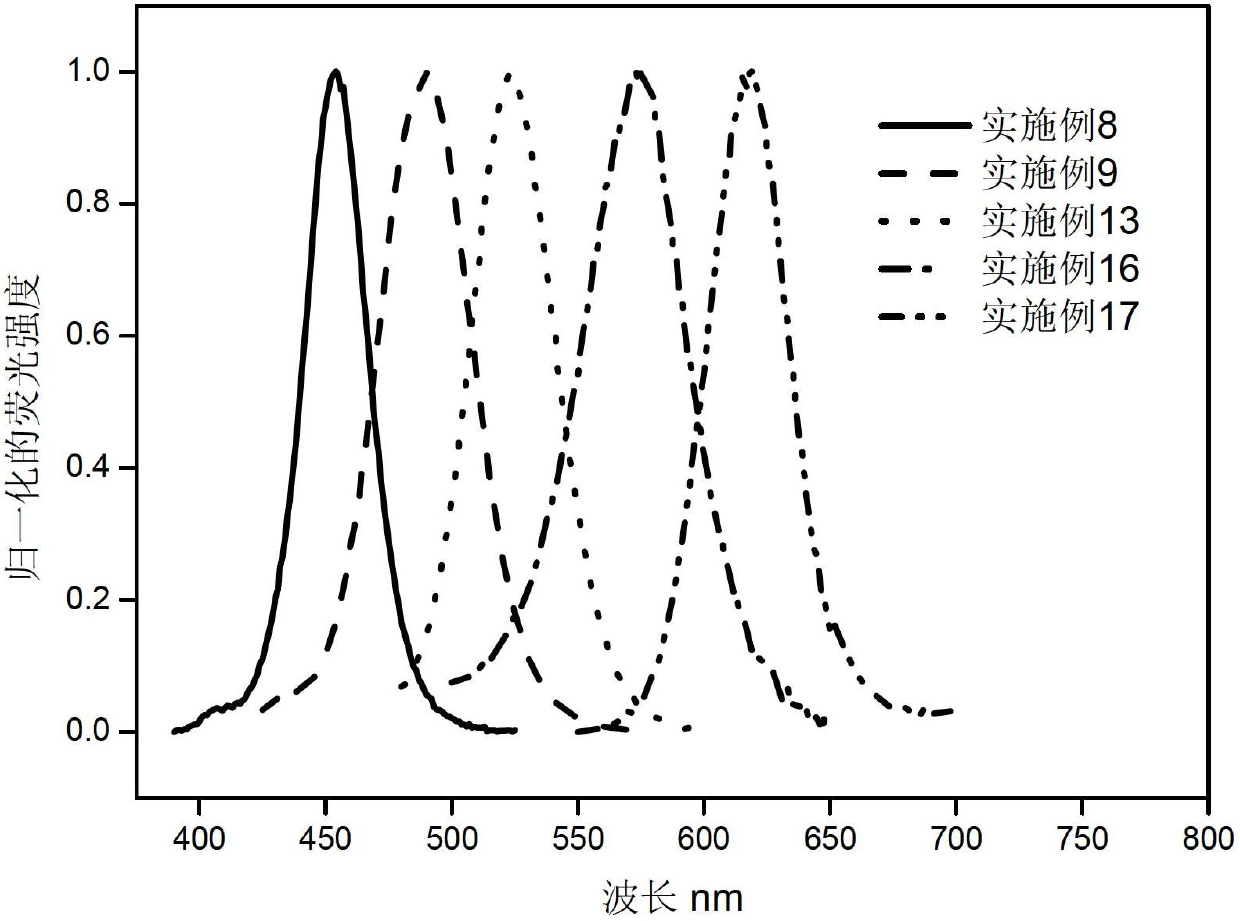

Examples

Embodiment 1

[0028] The preparation of embodiment 1 cadmium source

[0029] Mix 1 mol of cadmium acetate and 4 mol of oleic acid, vacuumize and fill nitrogen three times repeatedly, react at 260°C for 1 hour, cool to room temperature, add 1-octadecene to make cadmium oleate with a concentration of 0.1 mol / L 1-octadecene solution, spare.

Embodiment 2

[0030] The preparation of embodiment 2 cadmium sources

[0031] Mix 1 mol of cadmium oxide and 2 mol of oleic acid, vacuumize and fill nitrogen three times repeatedly, react at 280°C for 2 hours, cool to room temperature, add 1-octadecene to make cadmium oleate with a concentration of 0.1 mol / L 1-octadecene solution, spare.

Embodiment 3

[0032] The preparation of embodiment 3 zinc sources

[0033] Mix 1 mol of zinc acetate and 2 mol of oleic acid, repeatedly evacuate and fill with nitrogen for 3 times, react at 270°C for 1 hour to obtain zinc oleate, cool to room temperature, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com