Heat storage and heat insulation material based on solar photothermal conversion and its preparation method

A technology for light-to-heat conversion and thermal insulation materials, which is applied in the manufacture of rayon, hollow filaments, chemical characteristics of fibers, etc. It can solve the problems of no heat storage and thermal insulation materials, inconvenient control of fiber color, and single fiber color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

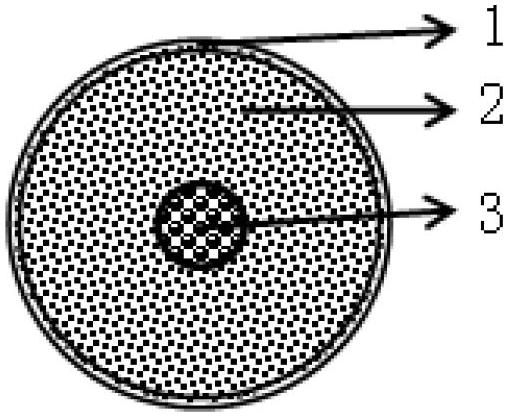

[0024] A heat storage and thermal insulation material based on solar photothermal conversion, which is composed of a carrier and additives in the form of particles attached to the carrier. Refer to figure 1 , the carrier is artificial polymer PTA 2, the additive is composed of metal and semiconductor, the metal is Cu particles 3, the semiconductor is Si particles 1, the mass ratio of artificial polymer PTA, metal Cu particles and semiconductor Si particles is 8:1:1 With metal Cu particles 3 as the core, artificial polymer PTA 2 as the main body, semiconductor Si particles 1 wrapped in the outermost layer as the surface layer, forming a cylindrical structure with a circular cross section, wherein the metal Cu particles and the semiconductor Si particles The equivalent diameter is 5nm.

[0025] A preparation process for heat storage and heat preservation materials based on solar photothermal conversion, comprising the following steps:

[0026] The first step is to prepare raw m...

Embodiment 2

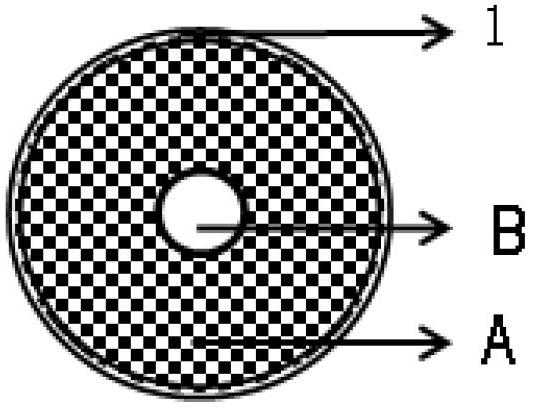

[0031] A heat storage and thermal insulation material based on solar photothermal conversion, which is composed of a carrier and additives in the form of particles attached to the carrier. Refer to figure 2 , the carrier is a mixture A of artificial polymer PTA and additive metal Cu particles, the interior is a hollow part B, and the outer surface is semiconductor Si particles 1, and the mass ratio of artificial polymer PTA, metal Cu particles and semiconductor Si particles is 8: 1:1; with the hollow part B as the core, the mixture A of the artificial polymer PTA and the additive metal Cu particles as the main body, and the semiconductor Si particles 1 wrapped in the outermost layer as the surface layer, forming a hollow cylindrical structure with a circular cross section , wherein the equivalent diameter of metal Cu particles and semiconductor Si particles is 5nm, the proportion of the hollow part B to the whole is 1%, and the thickness of the surface layer is 50nm.

[0032]...

Embodiment 3

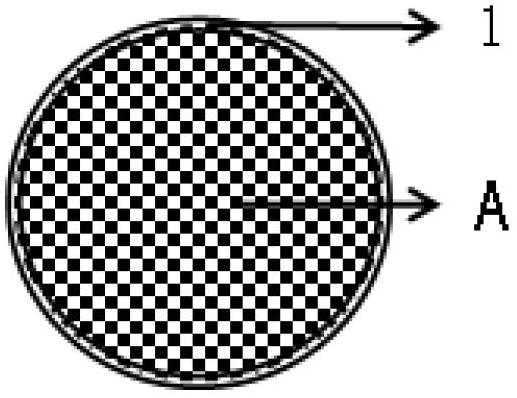

[0038] A heat storage and thermal insulation material based on solar photothermal conversion, which is composed of a carrier and additives in the form of particles attached to the carrier. Refer to image 3 , the carrier is a mixture A of artificial polymer PTA and additive metal Cu particles, the outer surface is semiconductor Si particles 1, the mass ratio of artificial polymer PTA, metal Cu particles and semiconductor Si particles is 8:1:1; The mixture A of the polymer PTA and the additive metal Cu particles is the main body, and the semiconductor Si particles 1 are wrapped in the outermost layer as the surface layer, forming a solid cylindrical structure with a circular cross section; wherein, the equivalent of the metal Cu particles and the semiconductor Si particles The diameter is 5nm, and the thickness of the surface layer is 50nm.

[0039] A preparation process for heat storage and heat preservation materials based on solar photothermal conversion, comprising the foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com