Method for dyeing ultra-black polyester fabrics

A technology of polyester fabric and dyeing method, which is applied in the field of textile printing and dyeing processing, can solve the problems of increased cost, decreased dye fastness, limited blackness of polyester fabric, etc., and achieves the effect of good depth and full shade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

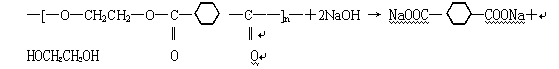

Method used

Image

Examples

Embodiment 1

[0019] The type of fabric used for dyeing is 68" Zhigong. Firstly, the THEN AF450 type air-flow dyeing machine is used for scouring and wrinkling, so that the shrinkage rate of the polyester fabric is controlled to 12%. After that, it is treated at 195°C for 45s for pre-setting treatment. The polyester fabric The alkali reduction rate of the fabric is kept at 10% by rolling the lye and steaming the alkali reduction treatment.

[0020] The dyeing process prescription of polyester fabric is: 150% dispersion liquid black 14% (owf), 200% dispersion green blue S-GL0.4% (owf), the amount of dyeing accelerator is 1g / l, with 0.5g / l acetic acid Adjust the pH value of the dye solution to 4.5-5.5, dye at 135°C for 60 minutes, and wash the polyester fabric at 80°C for 15 minutes with 1.3g / l acidic reducing cleaning agent after dyeing. The dyeing accelerator is: after mixing the two components of dioctyl phthalate and benzyl salicylate according to the mass ratio of 70%:30%, add 6% polyoxy...

Embodiment 2

[0024] The type of fabric used for dyeing is 68" thread satin. Firstly, the screw cylinder (Taiwan Donggeng Dyeing and Finishing Machinery) is used to refine and wrinkle, so that the shrinkage rate of the polyester fabric is controlled at 14%. The presetting condition is 45s at 190°C 。The polyester fabric undergoes intermittent alkali weight reduction treatment to keep the alkali weight reduction rate of the fabric at 16%.

[0025] The dyeing process prescription of polyester fabric is: 150% dispersion liquid black 15% (owf), 200% dispersion green blue S-GL 0.73% (owf), the amount of dyeing accelerator is 1g / l, adjusted with 0.4g / l acetic acid The pH value of the dye solution is 4.5-5.5, and it is dyed at 135°C for 60 minutes. After dyeing, the polyester fabric is washed with 1.2g / l acidic reducing cleaning agent at 85°C for 15 minutes. The dyeing accelerator is: after mixing the three components of diethylene glycol dibenzoate, dimethyl terephthalate and ethyl benzoate accord...

Embodiment 3

[0028] The type of fabric used for dyeing is 58" Saori hemp, and the air cylinder used in the scouring and wrinkling equipment controls the shrinkage rate of the polyester fabric to 19%. After that, it is treated at 200°C for 45s for pre-setting treatment. The polyester fabric is rolled with lye gas Alkali steaming and weight reduction treatment to keep the alkali weight reduction rate of the fabric at 22%.

[0029] The dyeing process prescription of polyester fabric is: 150% dispersion liquid black 16% (owf), 200% dispersion green blue S-GL0.5% (owf), the amount of dyeing accelerator is 1.2g / l, with 0.3g / l Adjust the pH value of the dye solution to 4.5-5.5 with acetic acid, dye at 135°C for 60 minutes, and wash the polyester fabric at 80°C for 20 minutes with 1.2g / l acid reduction cleaning agent after dyeing. The dyeing accelerator is: after mixing the three components of dimethyl terephthalate, ethyl benzoate and benzyl salicylate according to the mass ratio of 70%:25%:5%, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com