Cement-base light fireproof wall body heat insulation board and preparation method thereof

A fire wall, cement-based technology, used in thermal insulation, fire protection, building components and other directions, can solve the problems of poisoning and coma, environmental white pollution, combustion support, etc., to reduce white pollution, facilitate building construction, and fireproof building construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The wall thermal insulation board of the present invention is composed of a thermal insulation layer and a protective layer. When preparing the insulation layer, the mass ratio of water and PO52.5 cement is: 0.8, and the parts by weight of each component are as follows: (1Kg per part by weight)

[0020]

[0021]

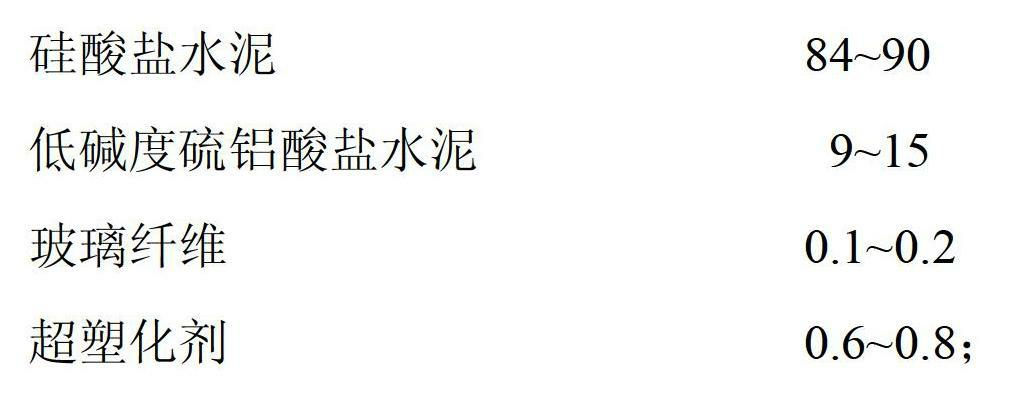

[0022] When preparing the protective layer, the mass ratio of water and PO52.5 cement is: 0.3, and the mass percentages of each component are as follows:

[0023]

[0024] After conventional curing for 28 days and drying at 90°C for 28 hours, the thickness of the cement-based lightweight firewall body insulation board is 3cm, and the thickness of the protective layer is 1mm; the technical performance test results are shown in Table 1.

[0025]

Embodiment 2

[0027] The wall thermal insulation board of the present invention is composed of a thermal insulation layer and a protective layer. When preparing the insulation layer, the mass ratio of water and PO42.5 cement is: 0.9, and the parts by weight of each component are as follows: (1Kg per part by weight)

[0028]

[0029] When preparing the protective layer, the mass ratio of water and PO42.5 cement is: 0.4, and the mass percentages of each component are as follows:

[0030]

[0031]

[0032] After 25 days of conventional curing and 24 hours of drying at 100°C, the thickness of the cement-based lightweight firewall body insulation board is 3cm, and the thickness of the protective layer is 2mm. The technical performance test results are shown in Table 1.

[0033]

Embodiment 3

[0035] The wall thermal insulation board of the present invention is composed of a thermal insulation layer and a protective layer. When preparing the insulation layer, the mass ratio of water and PO52.5 cement is: 1.0, and the parts by weight of each component are as follows: (1Kg per part by weight)

[0036]

[0037] When preparing the protective layer, the mass ratio of water and PO52.5 cement is: 0.5, and the mass percentages of each component are as follows:

[0038]

[0039] After 25 days of conventional curing and 24 hours of drying at 100°C, the thickness of the cement-based lightweight firewall body insulation board is 3cm, and the thickness of the protective layer is 1mm. The technical performance test results are shown in Table 1.

[0040]

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com