Tubular object displacement identification device based on machine vision

A machine vision and identification device technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as affecting detection accuracy, small radial size, and inability to achieve, to ensure measurement accuracy, ease of use, and high resolution. The effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

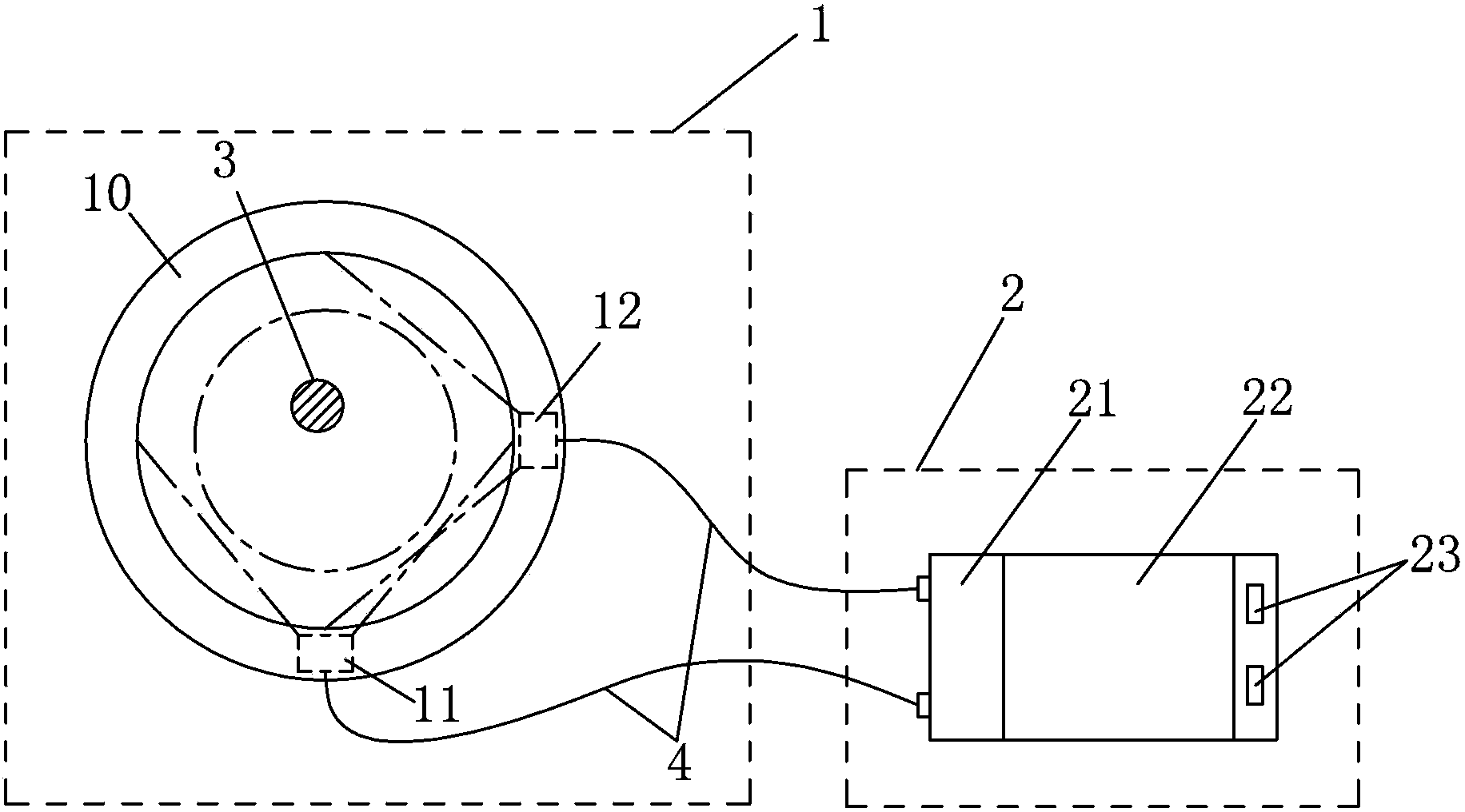

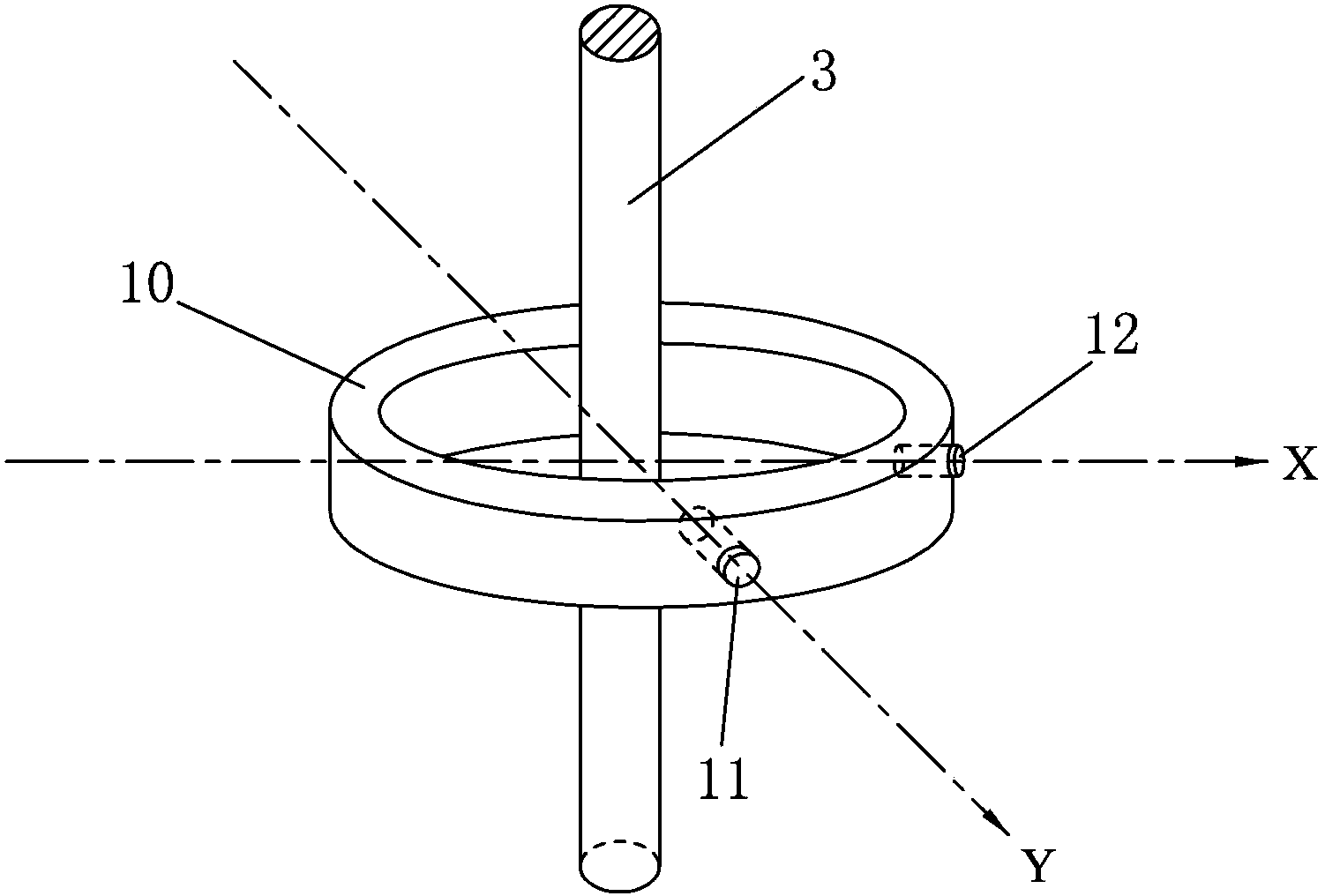

[0016] refer to figure 1 , figure 2 , a device for recognizing displacement of a tubular object based on machine vision provided by the present invention mainly includes an image acquisition device 1 and an image processing device 2 . In the image acquisition device 1, two cameras 11, 12 are fixedly mounted on the ring detector 10 perpendicular to and facing the cylindrical object 3 to be measured, and are respectively used to detect the object 3 to be measured passing through the ring detector 10 at X Axis and displacement in the Y-axis direction. In the image processing device 2, the two data lines 4 respectively input the images collected by the cameras 11 and 12 to the image acquisition card 21, and the image processing unit 22 processes the images, and describes the detection results and outputs them through the signal output port 23 .

[0017] In the described image acquisition device 1, its detector is a ring structure, and two cameras 11, 12 are fixedly installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com