Integrated micro pressure flow sensor based on silicon through-hole technology

A flow sensor and pressure sensor technology, which is applied in the measurement of fluid pressure through electromagnetic components, microstructure technology, fluid velocity measurement, etc., can solve the problems of high packaging cost and excessive packaging size, and reduce packaging size and packaging cost. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

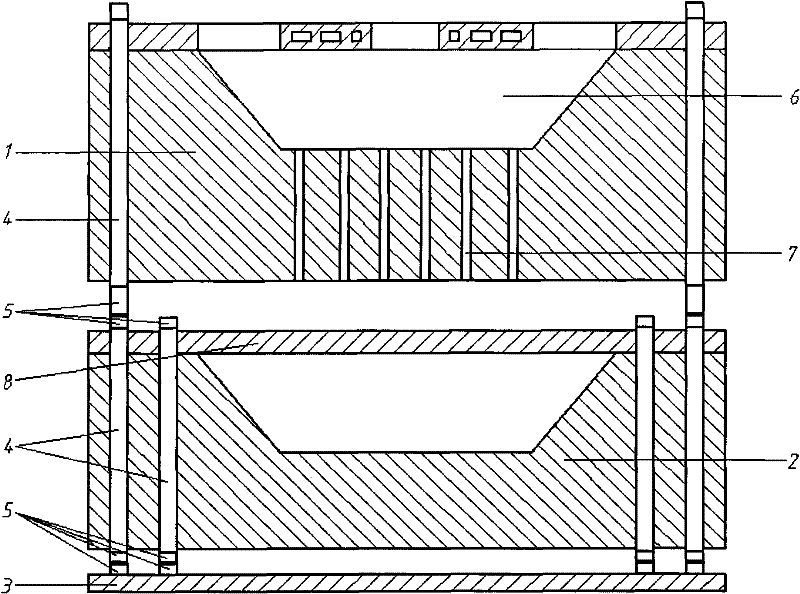

[0010] see figure 1 , The present invention is composed of MEMS pressure sensor, MEMS flow sensor, ASIC sensor signal conditioning chip 3, TSV interconnection hole 4, bump 5, and pressure introduction through hole 7. The MEMS flow sensor, MEMS pressure sensor, and ASIC sensor signal conditioning chips are vertically stacked in sequence, and are electrically connected through the TSV interconnection holes 4 and bumps 5 . The ASIC sensor signal conditioning chip 3 performs signal conditioning on the MEMS pressure sensor and the MEMS flow sensor. The specific implementation steps are as follows:

[0011] 1. Etching at least one pressure introduction via hole 7 on the MEMS flow sensor substrate 1 . The pressure introduction through hole 7 communicates the cavity 6 of the MEMS flow sensor with the bottom surface of the MEMS flow sensor substrate 1, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com