Composite-structure Fresnel lens

A technology of Fresnel lens and composite structure, which is applied in the direction of lens, condenser, optics, etc., can solve the problems of low surface hardness, lower transmittance, and high packaging cost of PMMA materials, so as to improve optical transmittance and reduce transmittance. Efficiency reduction, good wind and sand resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

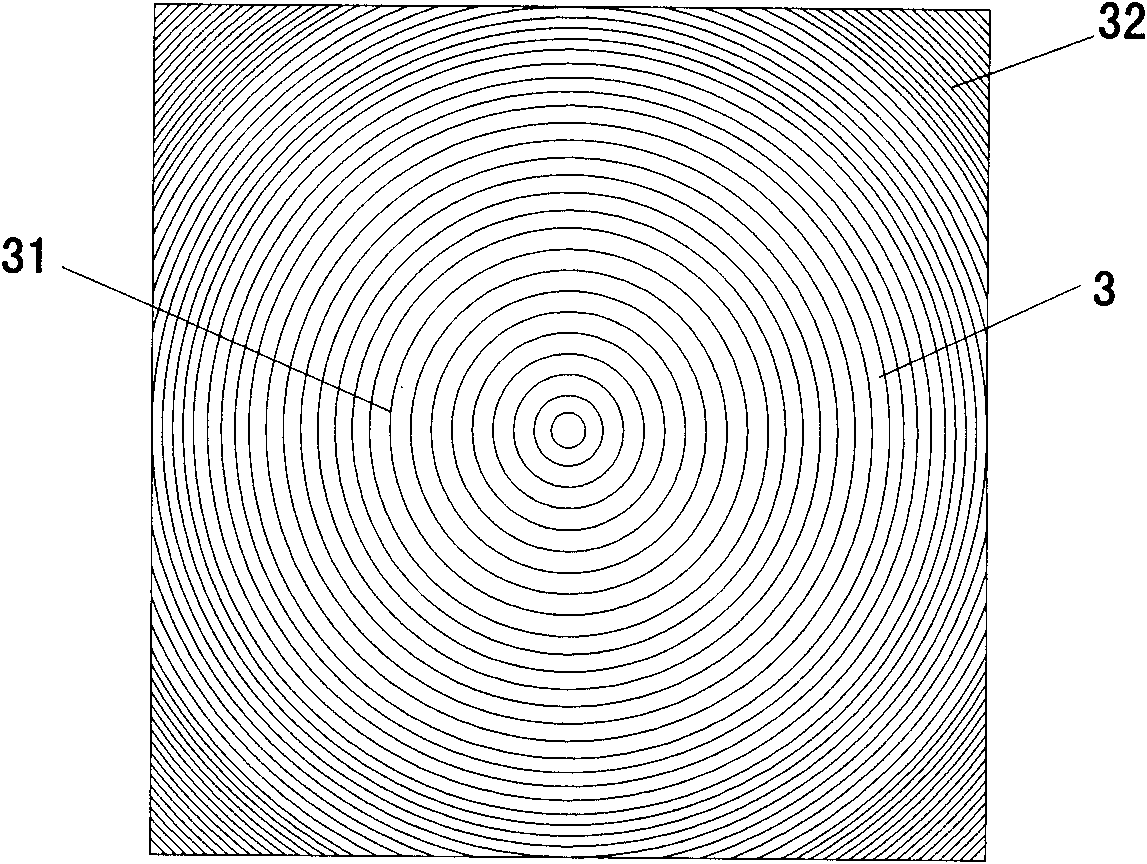

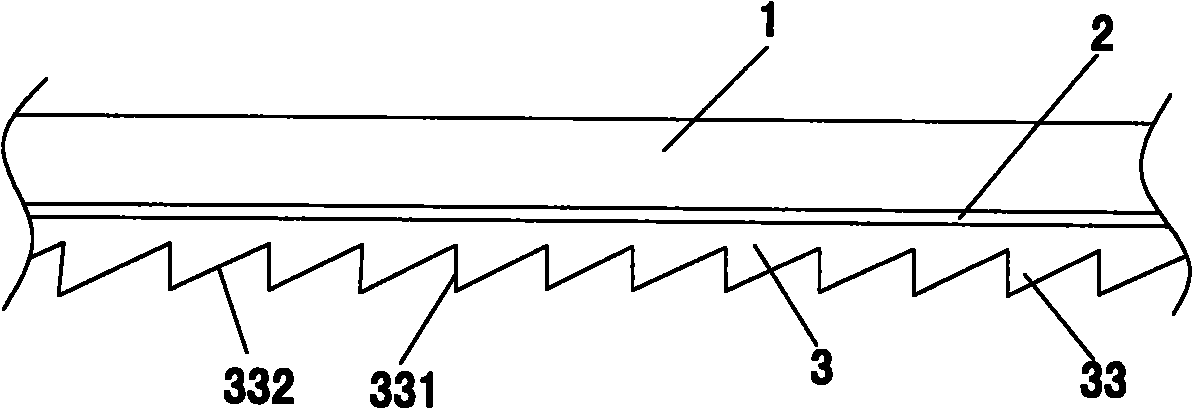

[0035] see figure 1 , figure 2 , the composite structure Fresnel lens of the present invention is formed by sequential connection of tempered flat ultra-clear glass 1, bonding layer 2 and silica gel layer 3, and the outer surface of silica gel layer 3 forms a Fresnel tooth-shaped surface, and the Fresnel tooth The shape surface is composed of a plurality of tooth-shaped concentric rings 31 or broken rings 32. The tooth-shaped cross-section of each ring is a right triangle 33, and the right angle side 331 of the right triangle is perpendicular to the upper surface of the Fresnel lens, that is, the incident surface of sunlight , the surface where the hypotenuse 332 is located forms the refraction surface of sunlight.

[0036] The toughened flat ultra-clear glass in the present invention has a thickness of 3-5 mm, and both sides are smooth surfaces; the thickness of the bonding layer is less than 0.1 mm; the thickness of the silica gel layer is not greater than 1 mm.

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com