Method for recycling metal iron from steel slag of converter

A converter steel slag and metal iron technology is applied in the field of recovering metal iron from converter steel slag and recovering metal iron resources. Investment cost and follow-up beneficiation cost, high metal iron recovery rate and product grade, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

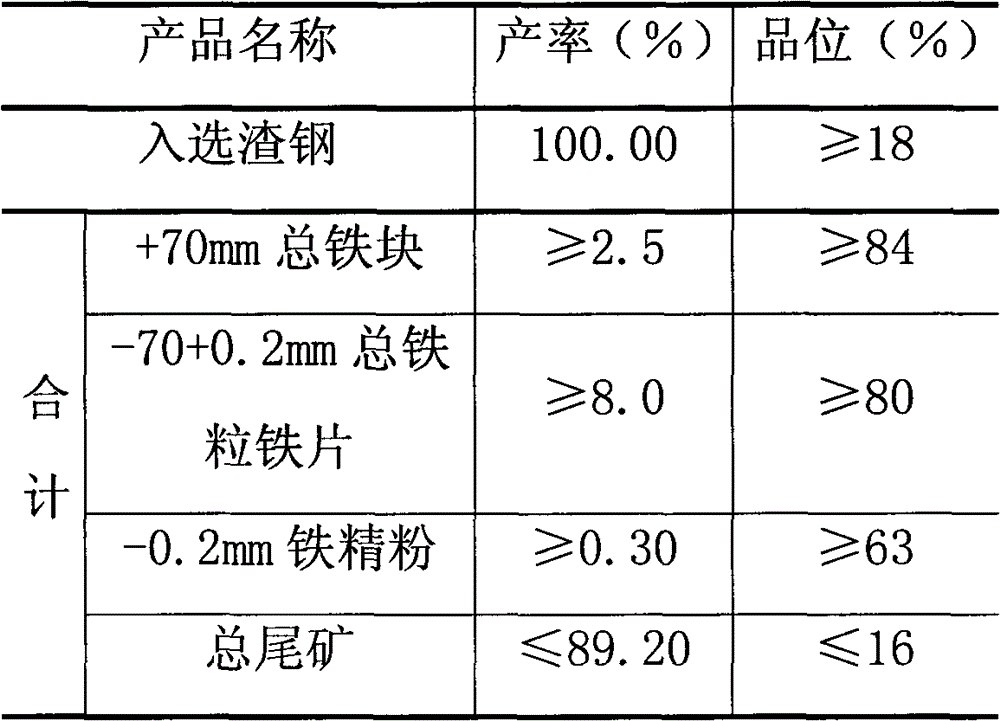

[0021] In a pilot test, the daily processing capacity is 20t / d, and the steel slag grade is 17.67%.

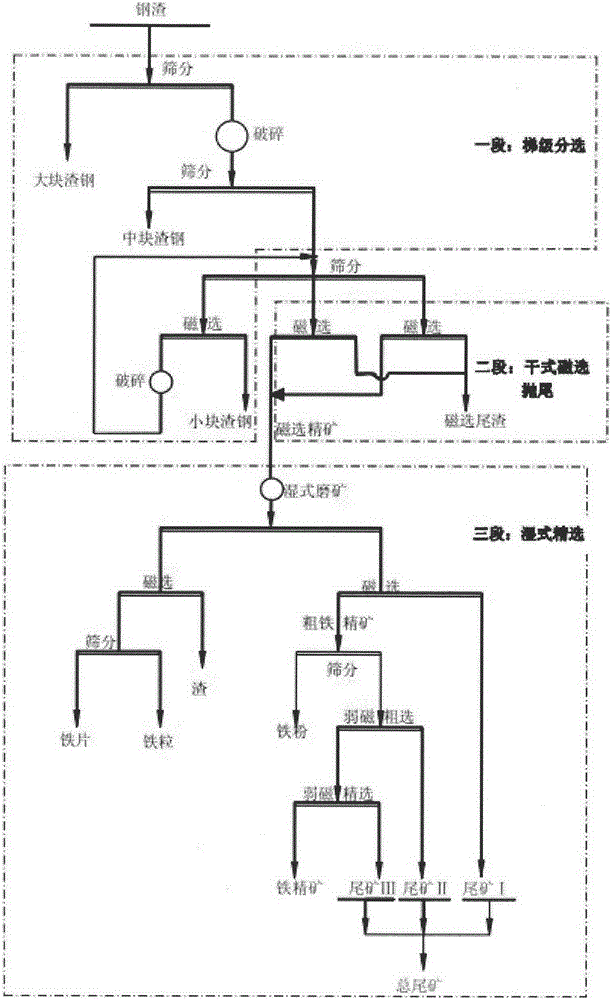

[0022] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod screen to recover the large slag steel of +300mm. Bar sieve screening and manual selection are used to select -300+130mm large slag steel, and the +130mm large steel slag is returned to the jaw crusher for crushing; -130mm steel slag is screened by a grading 70mm sieving machine into -130+70mm And -70mm two grades; -130+70mm steel slag is sorted with a magnetic pulley (magnetic field strength of 800Oe) to select the medium-130+70mm high-grade slag steel, and the -130+70mm tailings are crushed with a jaw crusher Return to 70mm sieving machine screening; -70mm steel slag is classified into -70mm+25mm sieving and -25mm two particle sizes for dry magnetic separation (magnetic drum) throwing, the magnetic field strength is...

Embodiment 2

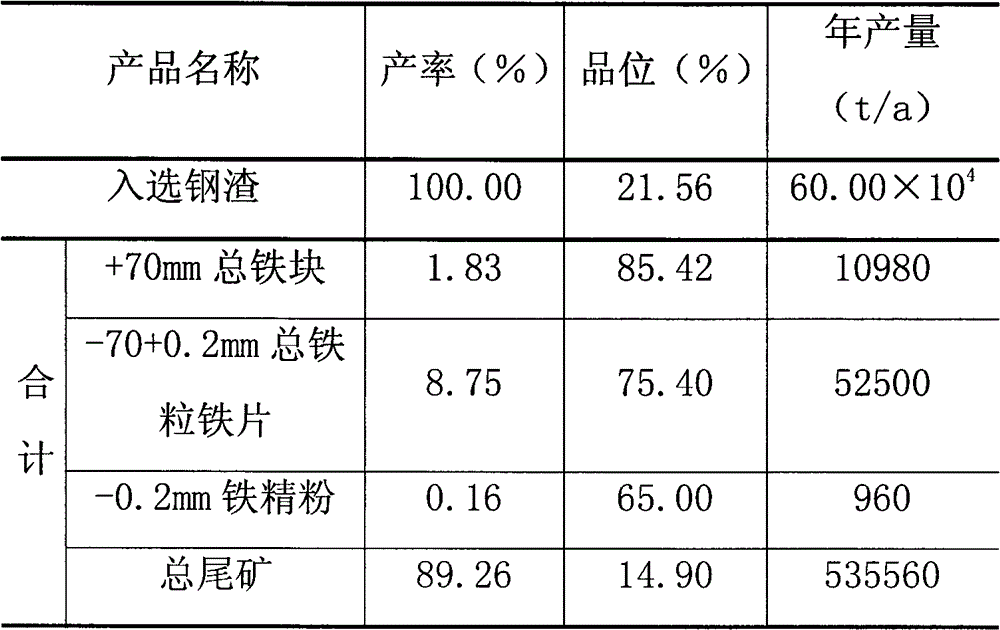

[0027] The annual output of converter steel slag in a large-scale steelmaking enterprise in Yunnan is 600,000t / a (2000t / d), and the grade of steel slag is 21.56.

[0028] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod screen to recover the large slag steel of +300mm. The large slag steel of -300+130mm and the steel slag of -130+70mm grain size are screened out by the bar sieve, which is further crushed by the jaw crusher and then passed through the sorting method of vibrating screen + magnetic pulley (magnetic field strength is 1000Oe) to select the middle block High-grade slag steel; -70mm coarse concentrate is wet-type full-size grinding with a rod mill (grinding time 15min), and the pulp after grinding is screened with a +1mm drum sieve, and the +1mm particle size obtained after screening After dry magnetic separation (1500Oe magnetic drum) to remove slag, then use +1...

Embodiment 3

[0033] The annual output of converter steel slag in a steelmaking enterprise in Yunnan is 260,000t / a, and the grade of steel slag is 20.98.

[0034] The metal iron in the converter steel slag is recovered by the method shown in the attached figure. The converter steel slag is firstly recovered by a rod screen to recover the large slag steel of +300mm. The large slag steel of -300+130mm and the steel slag of -130+70mm grain size are screened out by the bar sieve, which is further crushed by the jaw crusher and then passed through the sorting method of vibrating screen + magnetic pulley (magnetic field strength is 1800Oe) to select the middle block High-grade slag steel; -70mm coarse concentrate is wet-type full-size grinding with a rod mill (grinding time 20min), and the pulp after grinding is screened with a +1mm drum sieve, and the +1mm particle size obtained after screening After dry magnetic separation (2000Oe magnetic drum) to remove slag, use +10mm vibrating screen to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com