Reversing shifting conveyer device and conveyer system

A conveying device and conveying system technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of single conveying direction, limited production efficiency, waste of production space, etc., achieve high production efficiency and ensure accurate monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

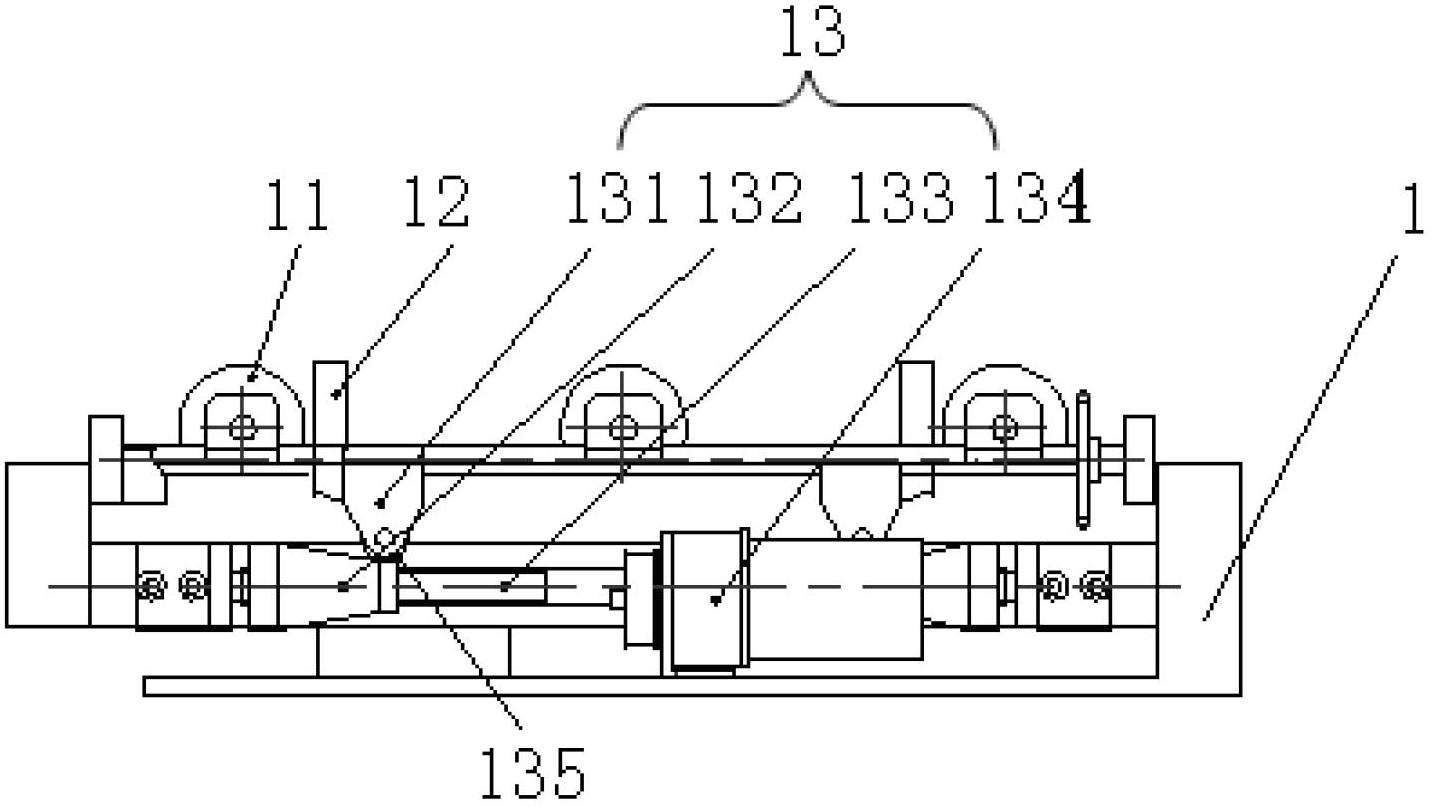

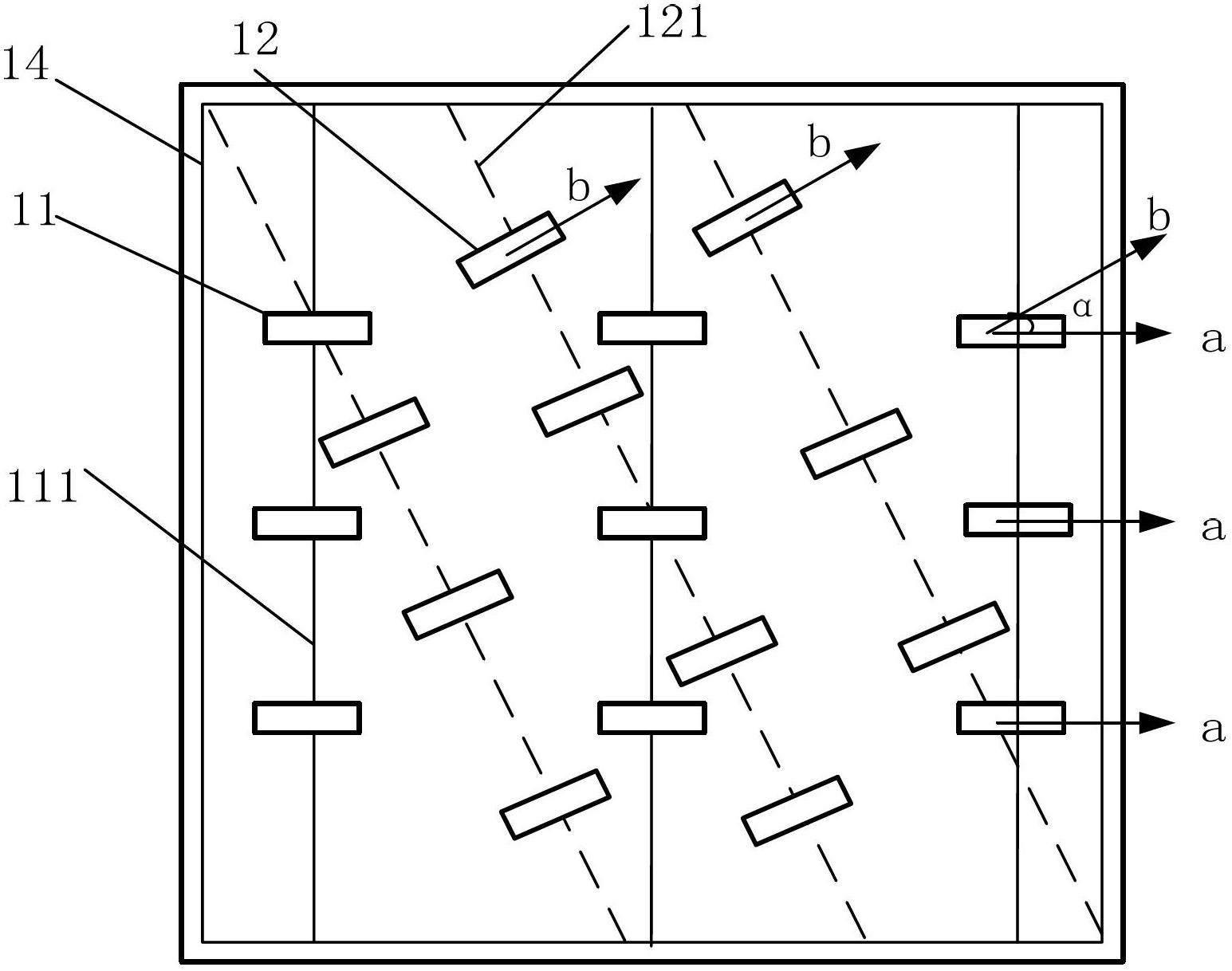

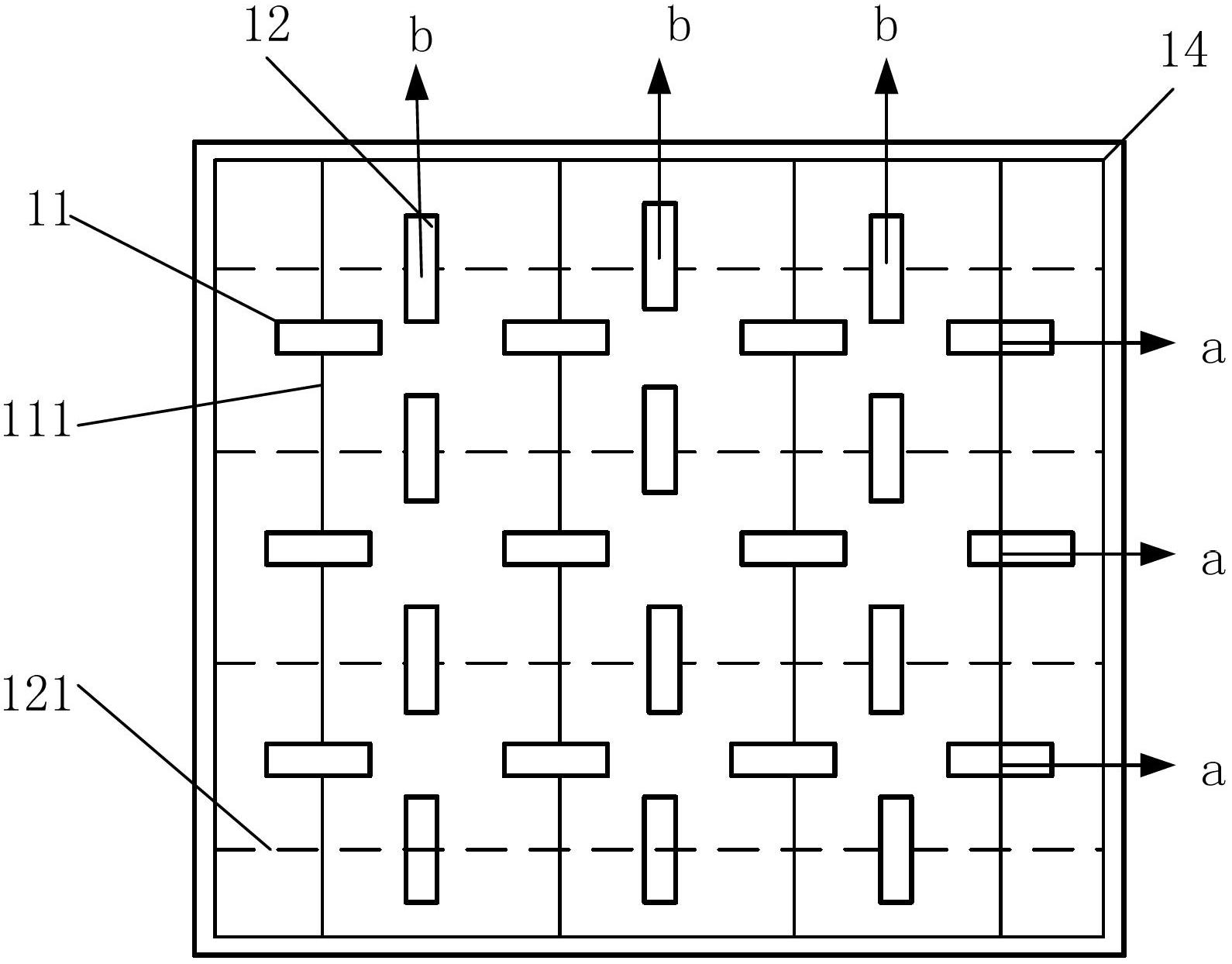

[0057] Example 1 as figure 1 , figure 2 As shown, the function of the reversing transfer conveying device 1 is to realize the reversing reloading and co-direction conveying of materials. The so-called reversing reloading is to change the original movement direction of materials, and the so-called same-direction conveying is to maintain the original movement of materials. direction. It includes multiple sets of fixed roller sets, multiple sets of reversing roller sets, a switching mechanism 13 and a frame 14, wherein each set of fixed roller sets includes a plurality of fixed roller sets 11, and the first conveying surface A is determined by the highest point of each fixed roller 11, The rolling direction of the fixed rollers 11 is the conveying direction a of the first conveying surface A; each set of reversing rollers includes a plurality of reversing rollers 12, and the second conveying surface B is determined by the highest point of each reversing roller 12, and the rever...

Embodiment 2

[0063] Embodiment 2, with respect to embodiment 1, both the first conveying surface A and the second conveying surface B can rise or fall relative to the frame 14, when the conveying direction of the material needs to be changed, then change the relative height of the two conveying surfaces, Realize the reversing transfer of materials from one conveying surface to the other; when the conveying direction of the material does not need to be changed, the relative height of the two conveying surfaces remains unchanged, and the material is conveyed along the conveying direction of the conveying surface.

Embodiment 3

[0064] Example 3 as Figure 5 As shown, the difference from Embodiment 1 or 2 is that each reversing roller 12 is driven by a reversing motor 122, so that each reversing roller 12 can realize a three-dimensional movement, that is, along a direction perpendicular to the center of the reversing roller. The diameter R of the shaft is for shaft rotation and vertical lift. Each reversing motor 122 runs synchronously, and the conveying direction b of the second conveying plane B formed by the highest point of the reversing roller 12 also changes thereupon. The angle α between the conveying directions b also changes accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com